Gas phase sample introduction bottle cleaning device

A technology for cleaning devices and sampling bottles, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as danger, time-consuming and laborious, and low work efficiency, and achieve compact structure, cost reduction, and improvement The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

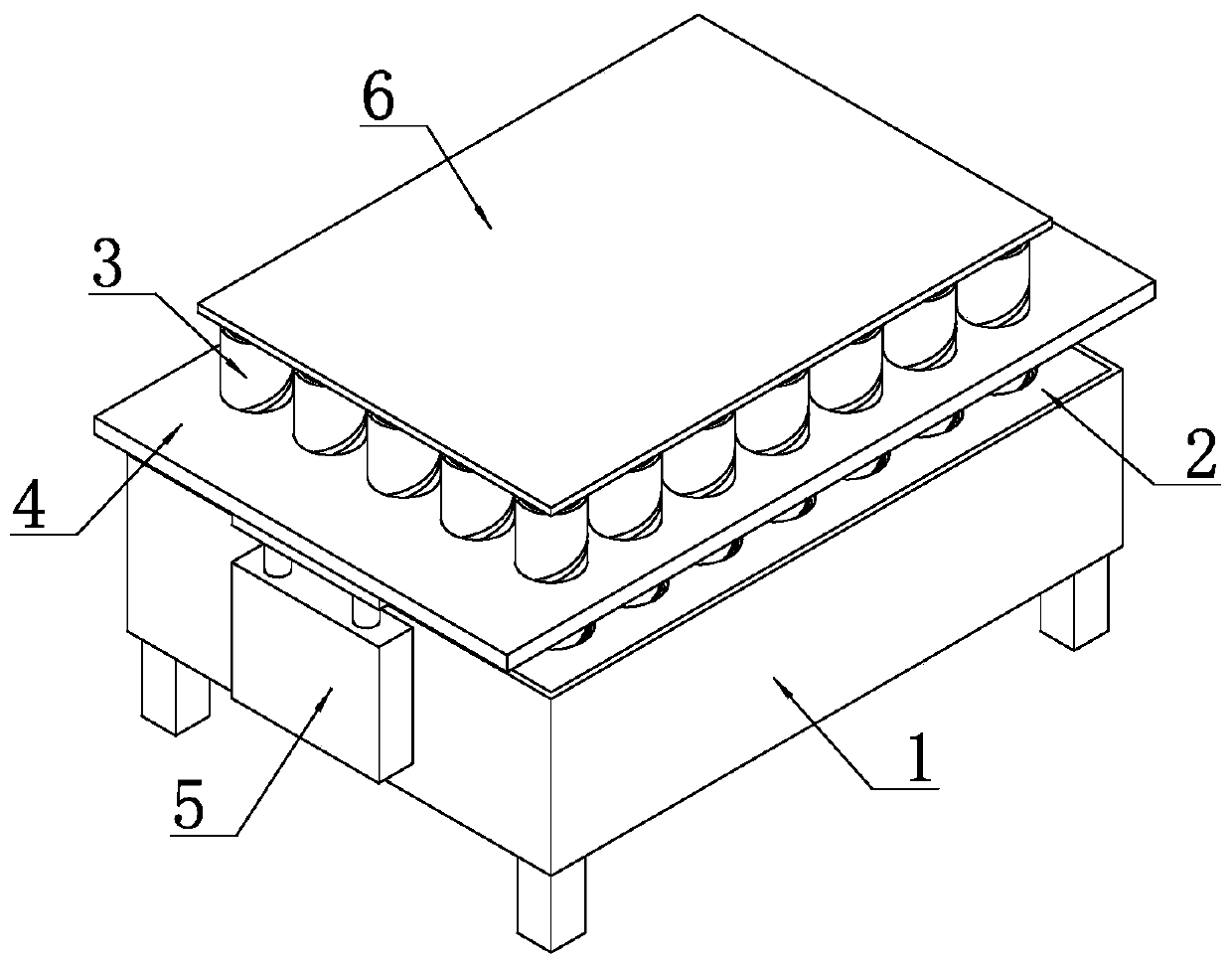

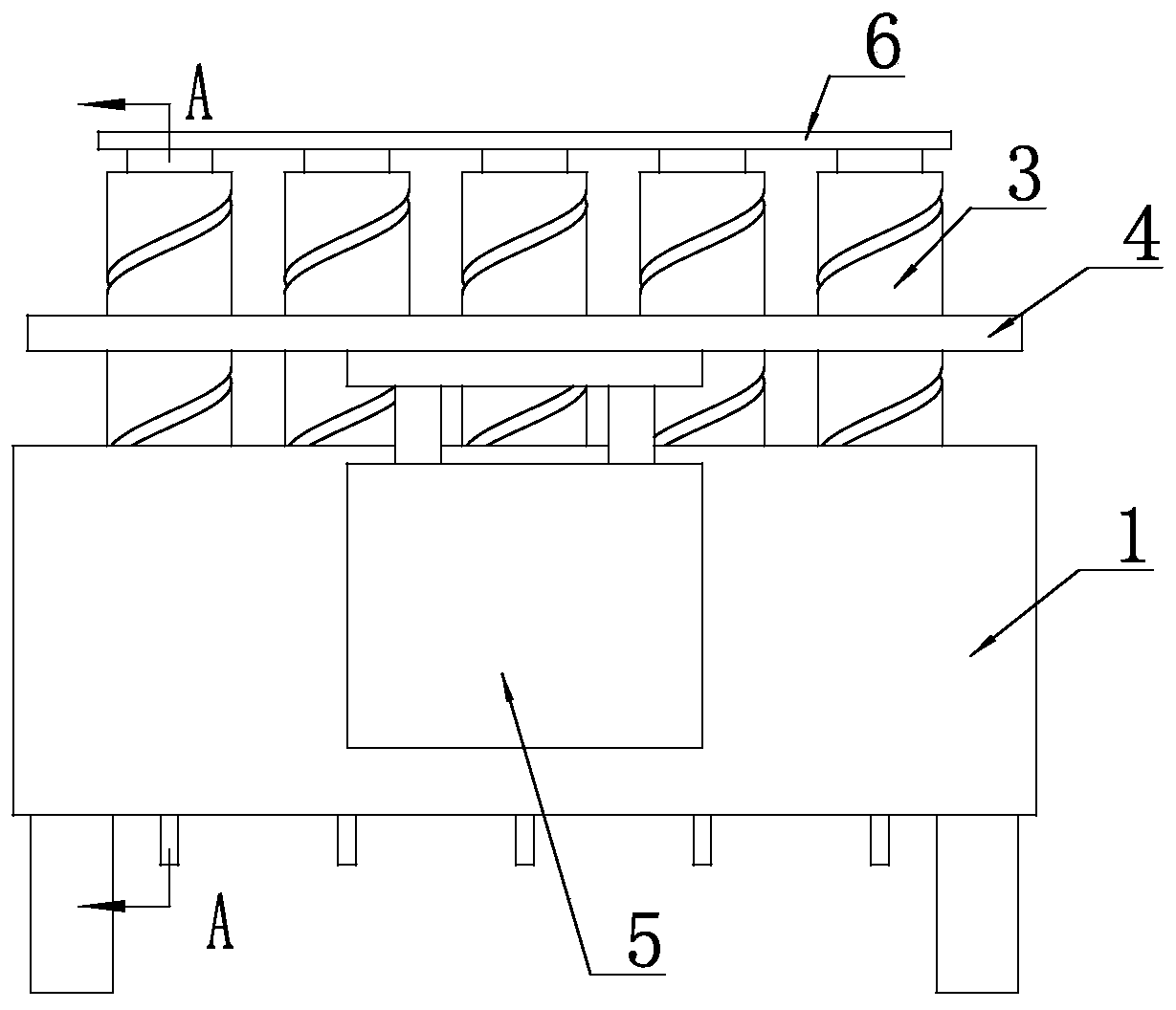

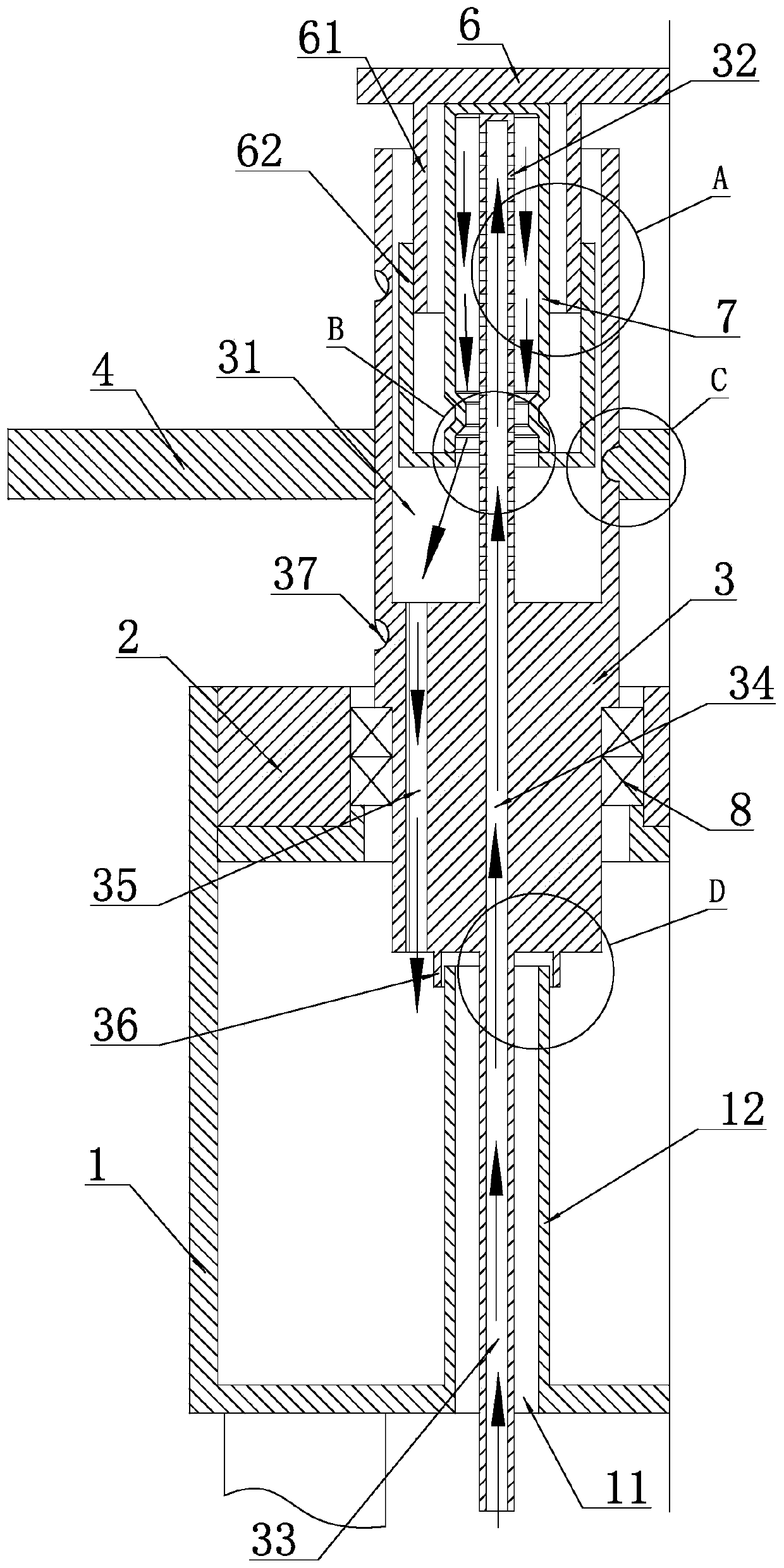

[0040] A device for cleaning a gas-phase sampling bottle 7 sequentially includes a cleaning unit and a fixing unit for fixing the gas-phase sampling bottle 7 from the bottom to the top.

[0041] like Figure 10 As shown, the fixing unit includes a fixing plate 6 , and a plurality of limit cylinders 61 for accommodating gas-phase sampling vials 7 are arranged on the lower side of the fixing plate 6 . As a specific implementation, there are 35 limiting cylinders 61 described in this embodiment, arranged in a matrix of seven rows and five columns. Each of the limiting cylinders 61 is provided with a compression cylinder 62 for compressing the gas phase sampling bottle 7 , and the compression cylinder 62 is threadedly connected to the limiting cylinder 61 . The compression cylinder 62 is provided with a first through hole 11, when the gas phase sampling bottle 7 is compressed in the limit cylinder 61, the mouth of the gas phase sampling bottle 7 passes through the first The thro...

Embodiment 2

[0057] The nozzle pipe 32, the drainage pipe 33 and the cleaning roller shaft 3 adopt a split structure, and the lower end of the nozzle pipe 32 is fixedly connected with the cleaning roller shaft 3 through a threaded connection, and the drainage pipe 33 The upper end is fixedly connected with the cleaning roller shaft 3 through threaded connection. All the other structures are the same as in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap