Split concrete core sample cutting device and cutting method thereof

A concrete core sample and cutting device technology, which is applied in the direction of working accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of concrete block vibration and displacement, low cutting efficiency, and two surfaces are not parallel, so as to improve practicability And applicability, safety performance improvement, mechanical energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

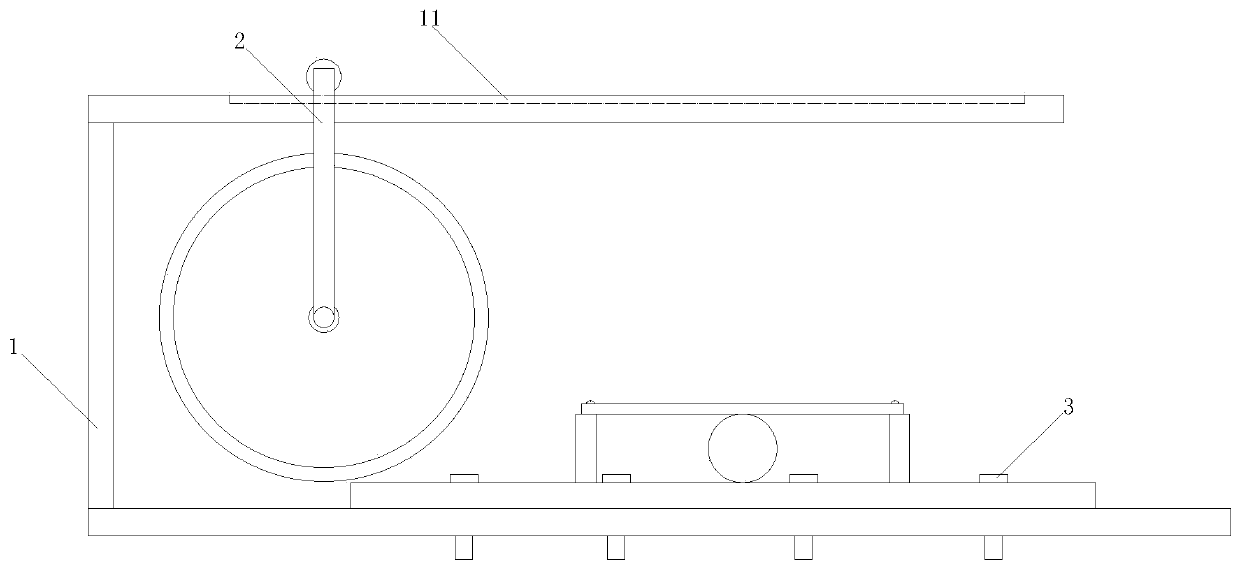

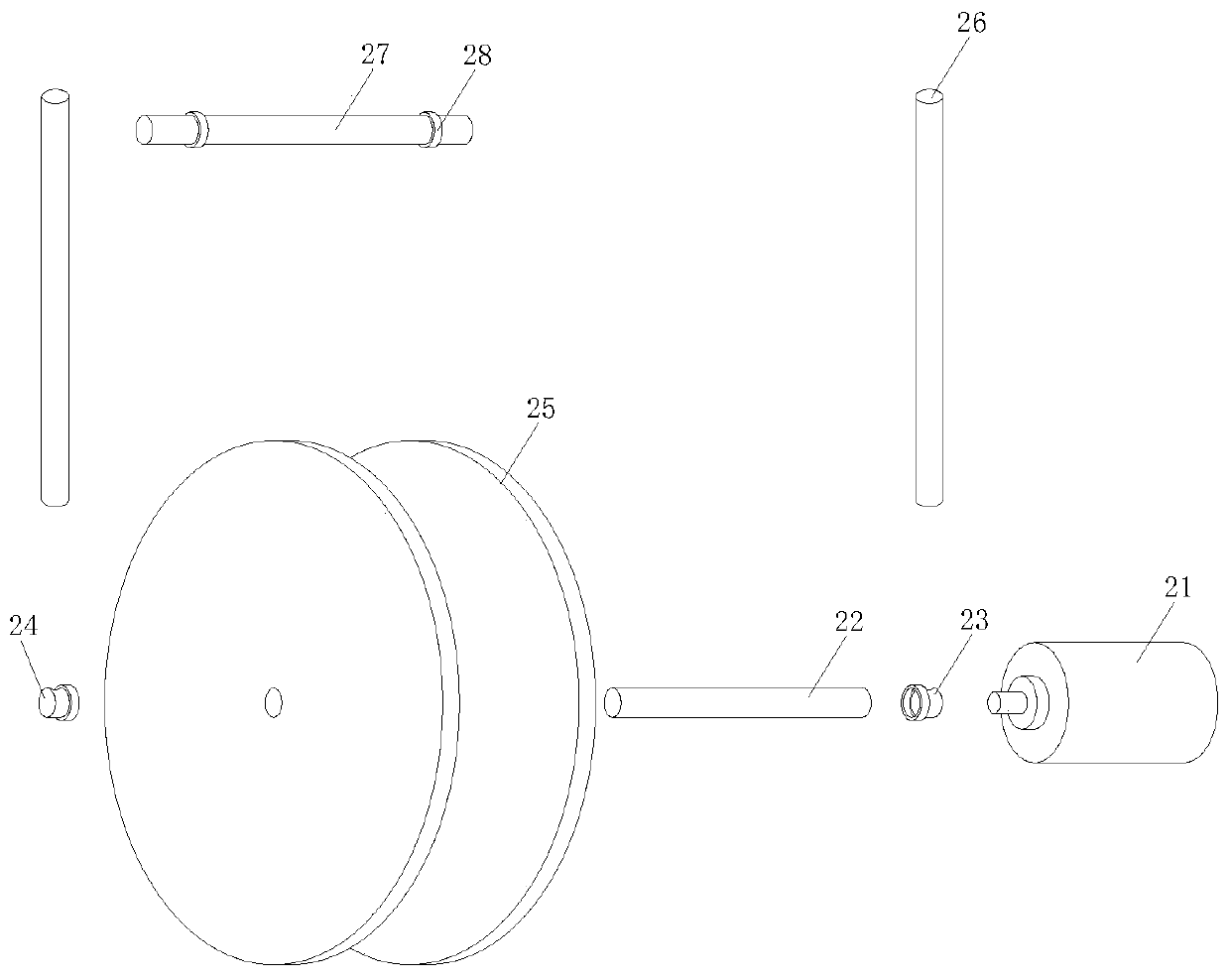

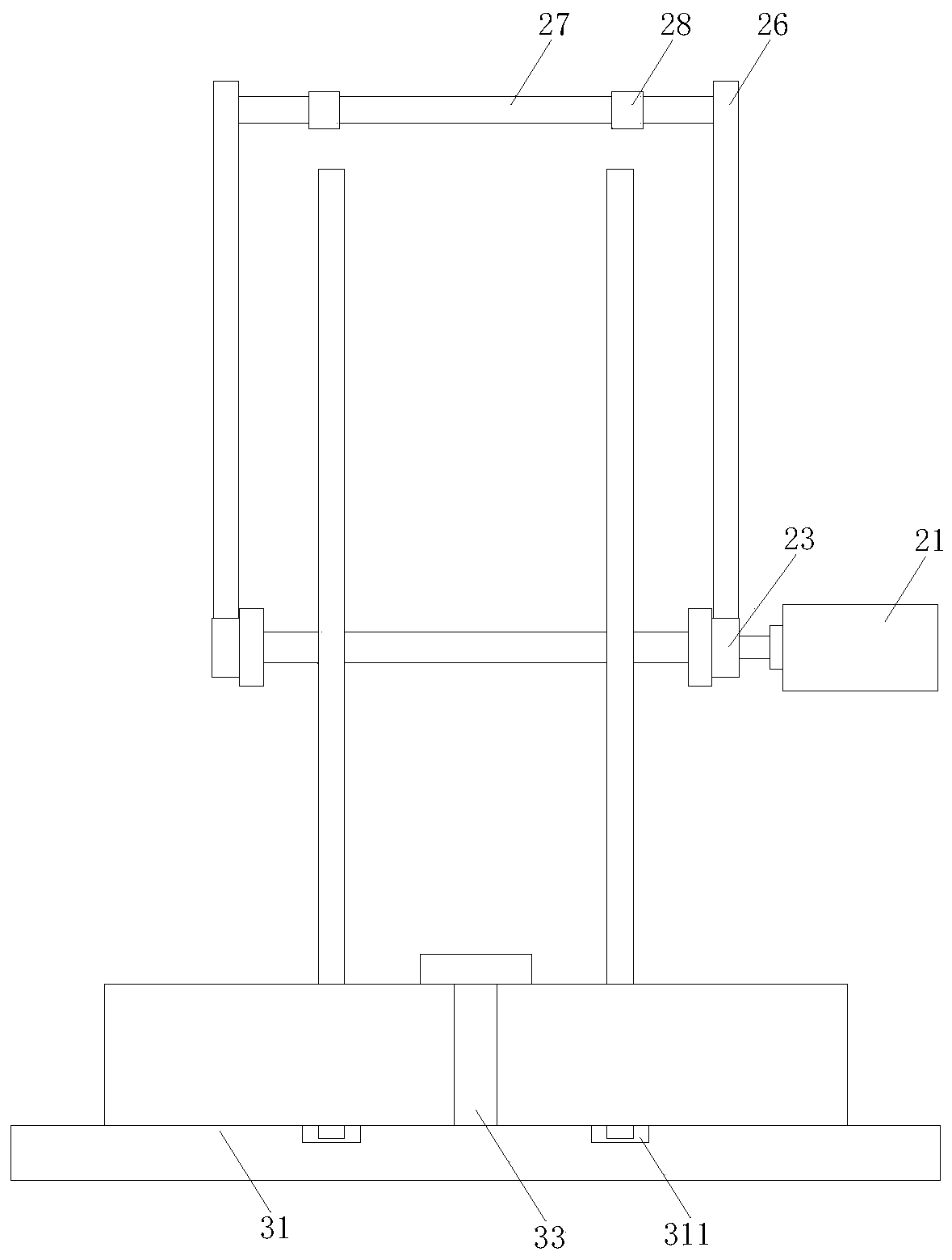

[0034] from figure 1 It can be seen that a double-parallel concrete core-like cutting device in this embodiment includes a workbench 1. A slideway 11 is provided on the upper surface of the workbench 1, and a cutting tool 2 is installed on the inner side of the slideway 11. figure 2 It can be seen that the cutting tool 2 is composed of a driving motor 21, a main shaft 22, a first bearing 23, a second bearing 24, a parallel blade 25, a connecting rod 26, a beam 27 and a roller 28, and the output end of the driving motor 21 is sleeved with a main shaft 22. The outer ring of the main shaft 22 is fixedly sleeved with a parallel blade 25. The parallel blade 25 is composed of two sets of parallel disc blades. The lower end of the blade extends to the inner side of the double blade groove 311. The inner groove surface of 311 is separated by 8mm-12mm to avoid the damage of the blade caused by the excessive cutting process. It has a protective effect on the concrete core sample and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com