Aircraft braked wheel rim

A technology for aircraft wheels and rims, applied in the directions of rims, wheels, wheels, etc., can solve the problems of increasing the risk of carbon oxidation of the brake disc and the weight of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

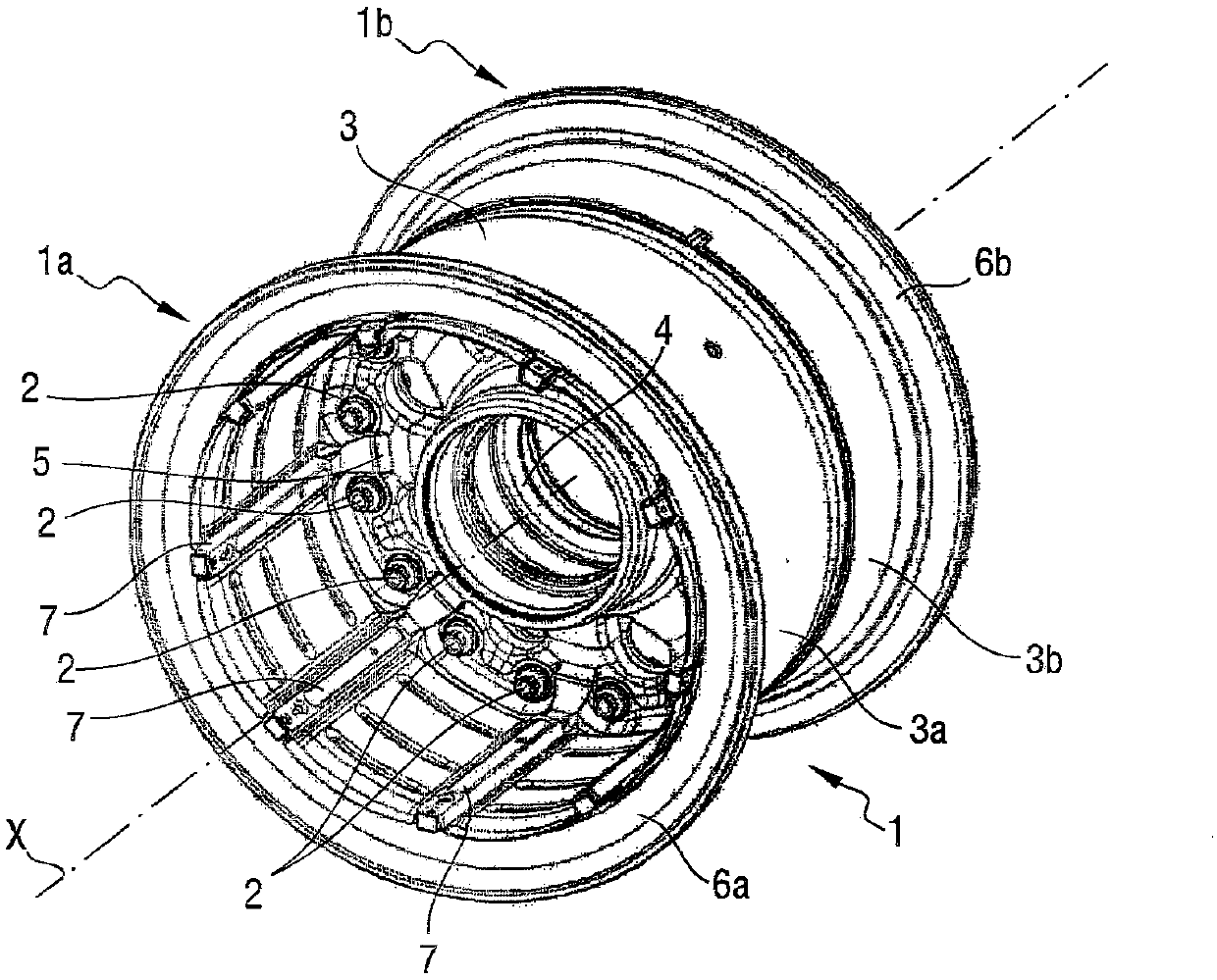

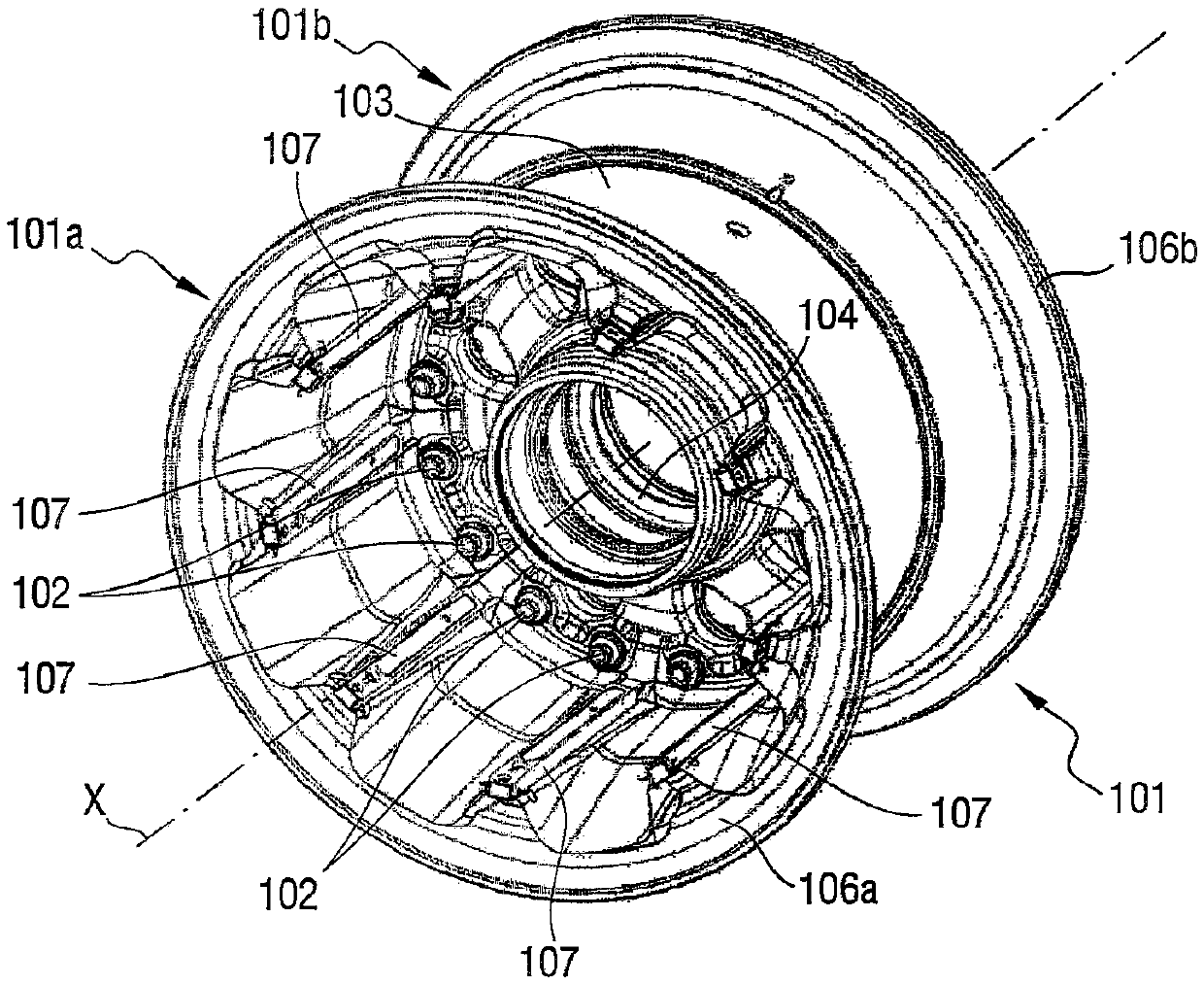

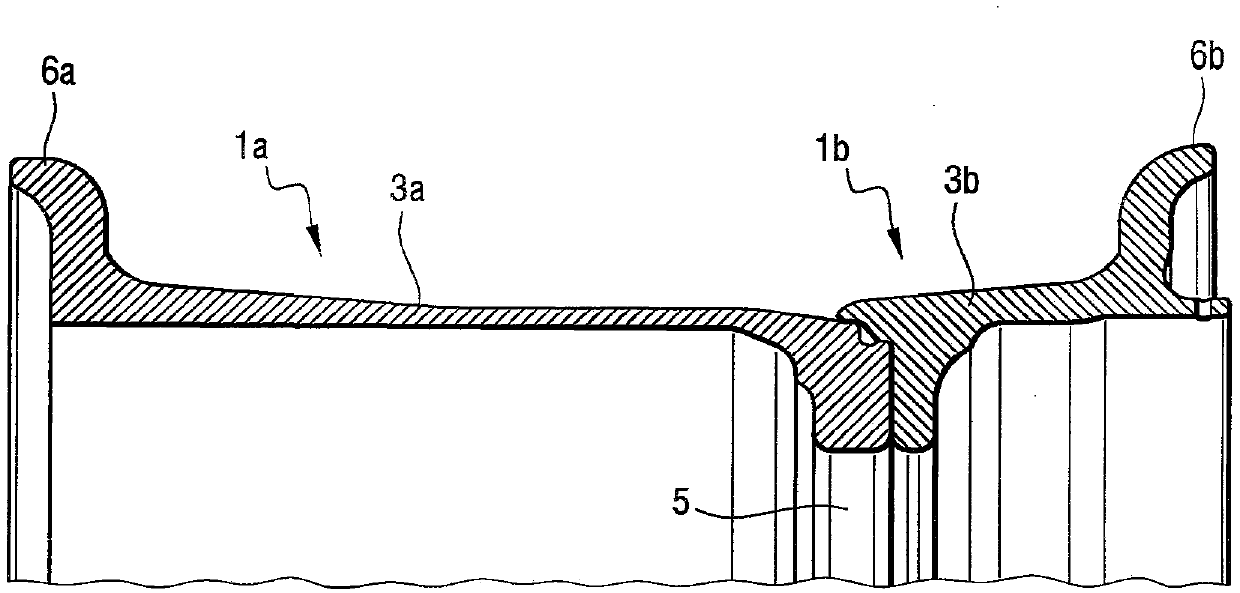

[0015] Figure 1A shows a rim 1 of a conventional brake wheel, consisting of two half-rims 1a and 1b, which are fastened to each other by bolts 2 passing through the disc. The rim 1 has an outer circular portion 3 for receiving a tire (not shown). The rim comprises a hub 4 connected to its outer circular part 3 by a perforated disc 5 . The hub 4 is intended to receive bearings for mounting the wheel on an aircraft landing gear axle such that the wheel rotates about an axis of rotation coinciding with the central axis X of the wheel. The outer circular part 3 comprises two parts 3a and 3b carried by two half-rims 1a and 1b respectively and terminated by respective flanges 6a, 6b. In this example, the half-rim 1a is intended to receive a brake disc and it comprises a ridge 7 extending parallel to the central axis X to receive a corresponding rod engaging in a peripheral notch in the brake disc. As can be seen from FIG. 2A , the profile of the outer circular portion 3 extends su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com