Floating type packaging dust collection mechanism

A vacuum mechanism, floating technology, applied in the field of floating packaging vacuum mechanism, can solve the time-consuming and labor-intensive problems, achieve good dust absorption effect, easy maintenance, and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

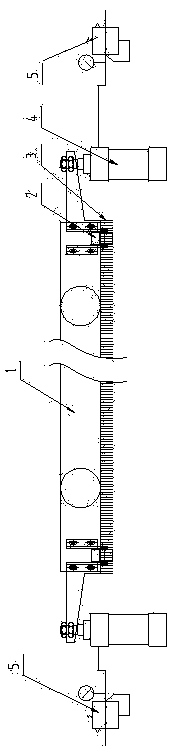

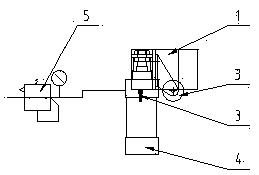

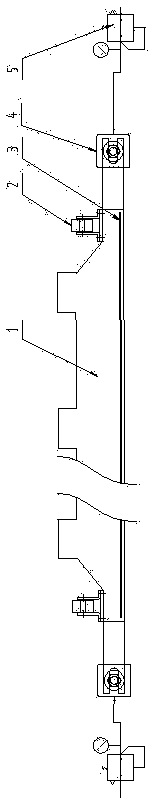

[0015] Accompanying drawing is a kind of specific embodiment of the present invention.

[0016] The floating packaging vacuum mechanism of the present invention includes a pusher dust suction rod 1 and a cylinder 4, and is characterized in that: a brush 3 is arranged under the push material suction rod 1, and the bottom of the brush is connected to a packing box conveyor belt, And the left and right ends of the push material suction rod 1 are respectively equipped with rollers 2; the two ends of the push material suction rod 1 are led out of the installed cylinder 4, and the control pipeline of the cylinder 4 is equipped with a pressure regulating valve 5; The vacuum rod 1 is provided with a vacuum suction device inside; the lower end of the brush 3 is at the same height as the lowest point of the roller 2 .

[0017] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. What described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com