Finely levelling robot with folding type connecting rod

A connecting rod and robot technology, applied in the field of precision leveling robots, can solve the problems of heavy workload, low work efficiency, and low leveling efficiency, and achieve the goal of expanding the leveling area, increasing the scope of leveling, and improving the efficiency of leveling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

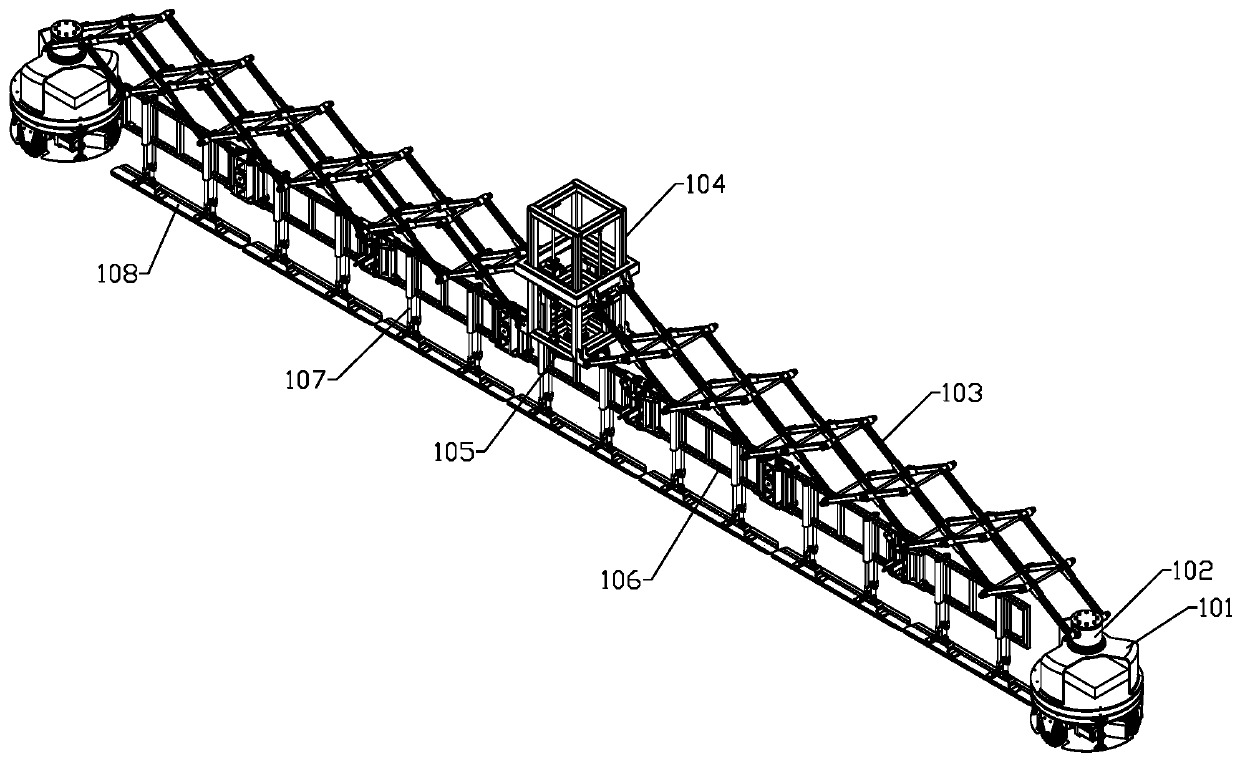

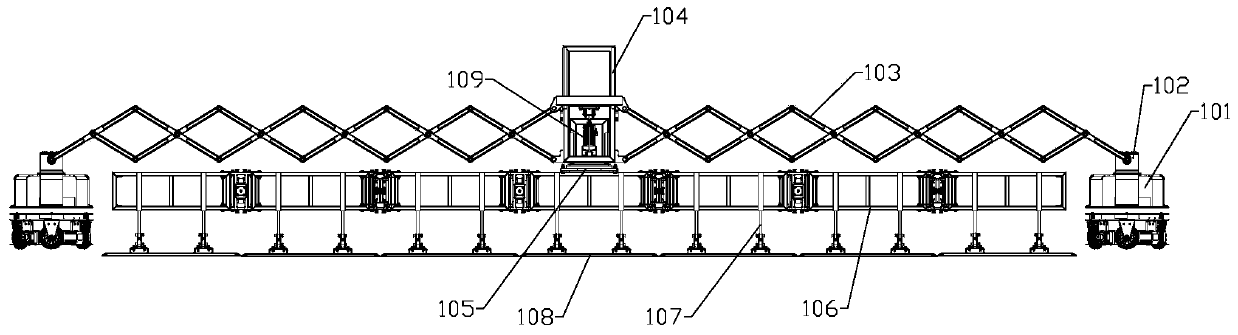

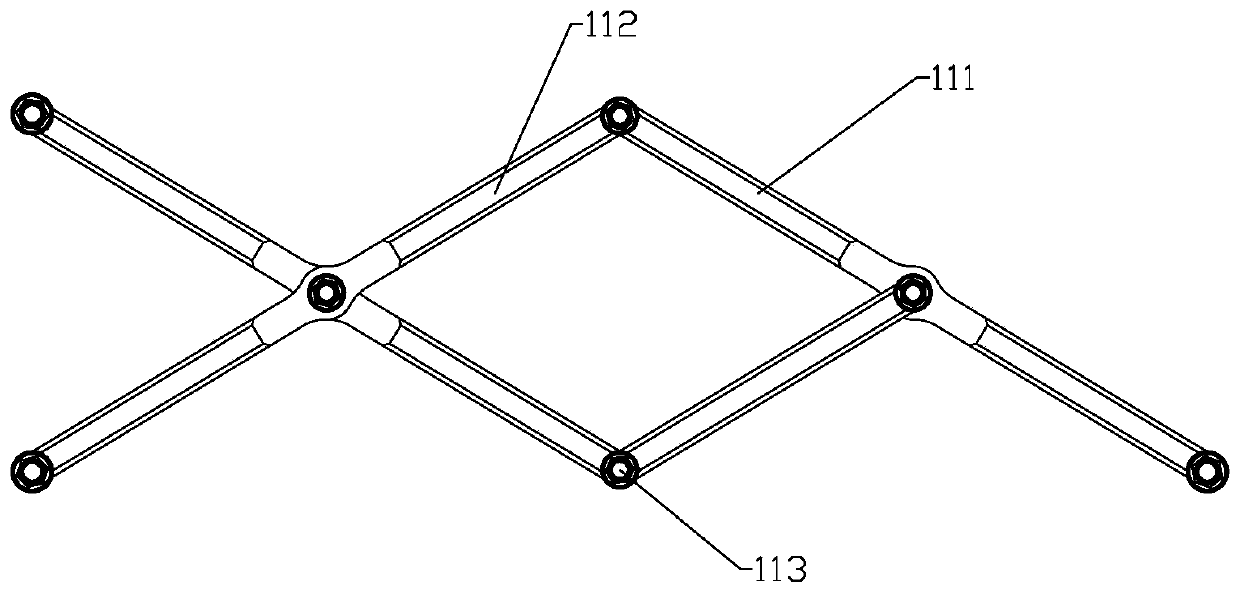

[0033] Please refer to figure 1 , this embodiment provides a precision flat robot with a foldable connecting rod, including a chassis 101, a deflection adjustment mechanism 102, a telescopic frame 103, a scraper telescopic actuator 106, a grain surface scraper 108, a telescopic support mechanism 104, a slewing support 105 and rotating motor 109, the precision flat robot adopts a double-drive chassis 101 shoulder-pick structure, and the connecting rod is the intermediate structure of the shoulder-pick type. The connecting rod includes a telescopic frame 103 and a telescopic support mechanism 104. The impurity removal assembly includes a slewing bearing 105, a scraper connection plate 110, a scraper telescopic actuator 106, and a grain surface scraper 108; The frame 103 includes two sections, the telescopic support mechanism 104 connects the two sections of the telescopic frame 103, the deflection adjustment mechanism 102 is connected to the chassis 101, the scraper telescopic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com