Novel engineering road paver

A paving machine and engineering technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of inconvenient crushing and mixing of stone materials, the progress of crushing and mixing, and the inability to carry out stone materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

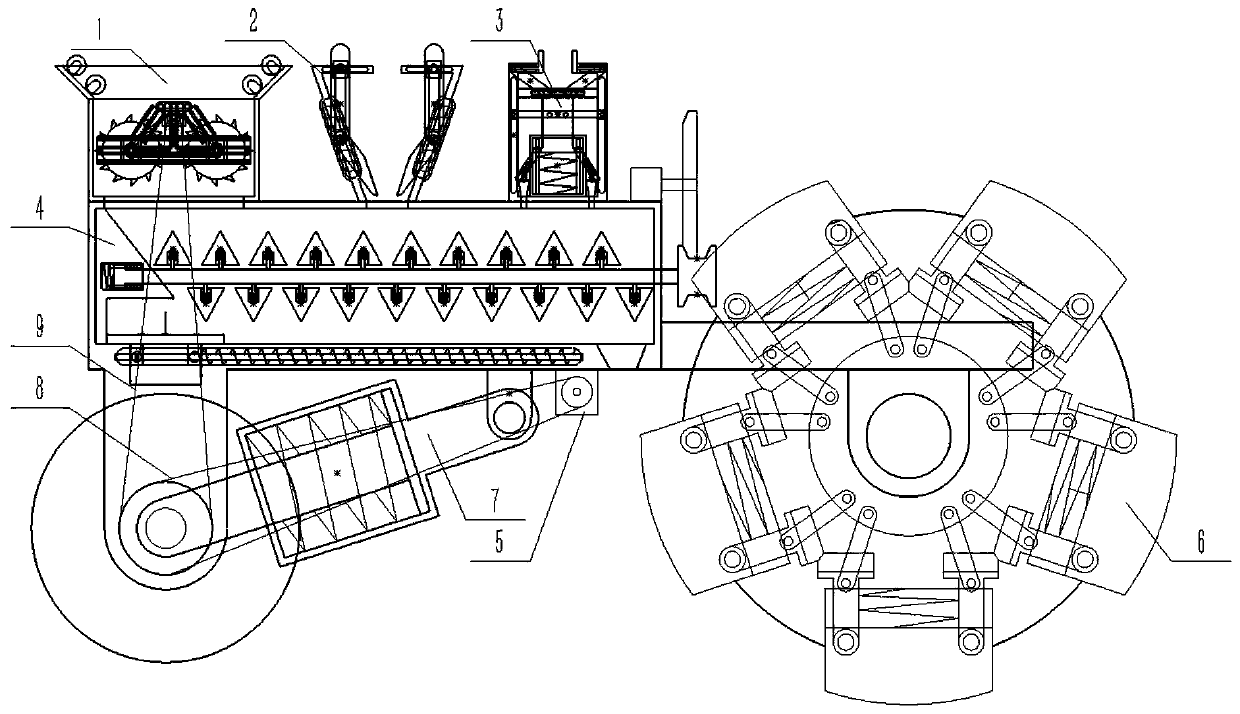

[0040] Combine below Figure 1-22 Description of this embodiment, a new type of engineering paving machine, including a stone crushing wheel 1, a mineral frame 2, a melting liquid device 3, a crushing and mixing device 4, a motor 5, a rolling wheel 6, a shock absorber 7, a synchronous belt 8 and Synchronous belt two 9, the stone crushing wheel 1, the mineral outer frame 2 and the melting liquid device 3 are all fixedly connected to the crushing and mixing device 4, and the stone crushing wheel 1, the mineral outer frame 2 and the melting liquid device 3 are all connected to the crushing and mixing device 4 is connected, the motor 5 is fixedly connected with the pulverizing and mixing device 4, the rolling wheel 6 is rotationally connected with the pulverizing and mixing device 4, the shock absorber 7 is hingedly connected with the pulverizing and mixing device 4, and the timing belt 18 is connected between the pulverizing and mixing device 4 and the motor 5 Between, two synchr...

specific Embodiment approach 2

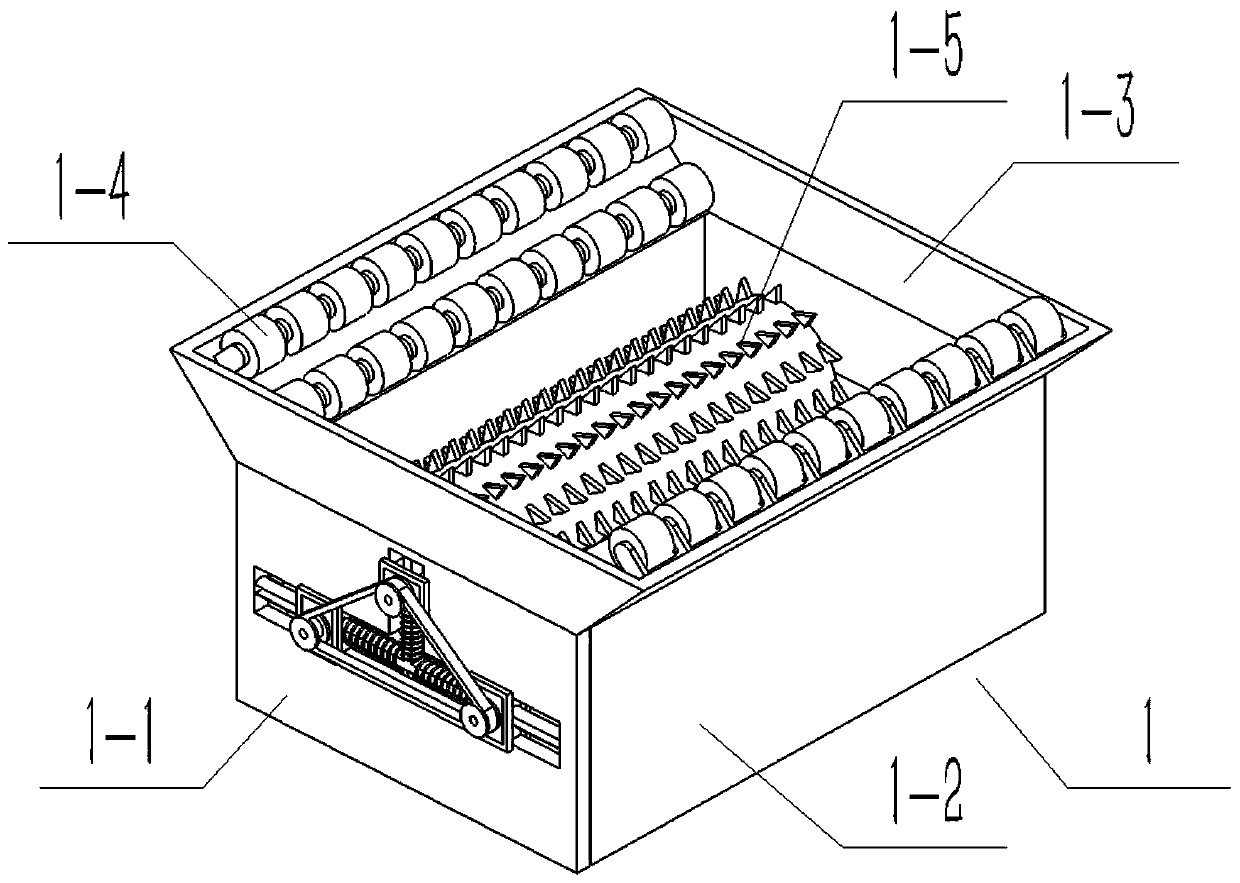

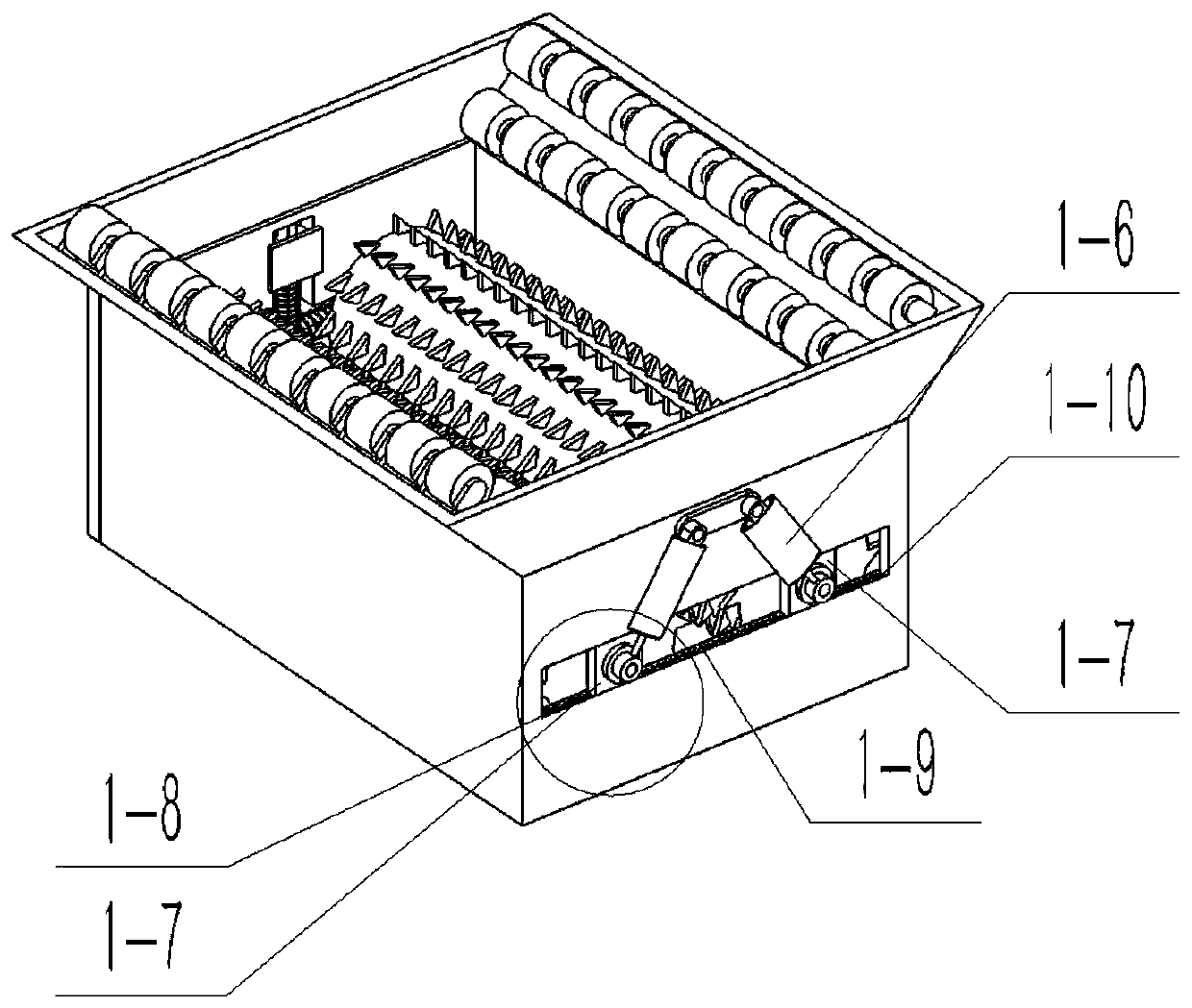

[0041] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain Embodiment 1. The stone crushing wheel 1 includes a front end frame device 1-1, a main body frame 1-2, an upper side frame 1-3, a rolling stone roller 1-4, Crushing roller 1-5, limit fit body 1-6, two hinged sliders 1-7, two sleeve springs 1-8, sleeve spring 2 1-9, cylindrical slide bar 1-10 and rectangular chute 1-11, the front-end frame device 1-1 includes a front-end vertical plate 1-1-1, a D-shaped sliding rod 1-1-2, a D-shaped chute 1-1-3, and a D-shaped rod sleeve spring 1-1 -4, the upper side sleeve spring 1-1-5, the connecting strip 1-1-6 and three sliding hinged terminals 1-1-7, the D-shaped chute 1-1-3 is arranged on the front vertical plate 1-1- The middle end of 1, the D-shaped sliding rod 1-1-2 is fixedly connected to the inner end of the D-shaped chute 1-1-3, the D-shaped rod sleeve spring 1-1-4 and the upper side sleeve spring 1-1-5 They are all socketed on the D-s...

specific Embodiment approach 3

[0043] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain Embodiment 1, the mineral outer frame 2 includes a mineral outer frame body 2-1, a material lever 2-2, a material push spring 2-3 and a material outlet 2-4 , the mineral frame body 2-1 includes a mineral frame 2-1-1, two frame side wall sliders 2-1-2, two frame side wall waist grooves 2-1-3 and a hollow cavity 2-1-4, the two outer frame side wall slide bars 2-1-2 are respectively arranged on the side walls of the mineral outer frame 2-1-1 of the body, and the waist grooves 2-1-3 of the two outer frame side walls are respectively On the side wall of the body mineral outer frame 2-1-1, the hollow cavity 2-1-4 is arranged at the inner end of the body mineral outer frame 2-1-1, and the material lever 2-2 includes the material lever Body 2-2-1, material lever slider 2-2-2, material lever slider 2-2-3 and material lever hinged terminal 2-2-4, material lever 2-2-3 and material lever The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com