Uniformization correction method for X-ray hardened artifact and based on spiral die bodies

An X-ray and beam hardening technology, applied in the field of multi-energy X-ray CT beam hardening calibration, can solve problems such as easy introduction of errors, need to re-measure, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

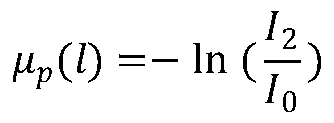

[0037] The invention combines the characteristics of industrial production to quickly and accurately measure the projection information of materials under X-rays.

[0038] 1. Model design

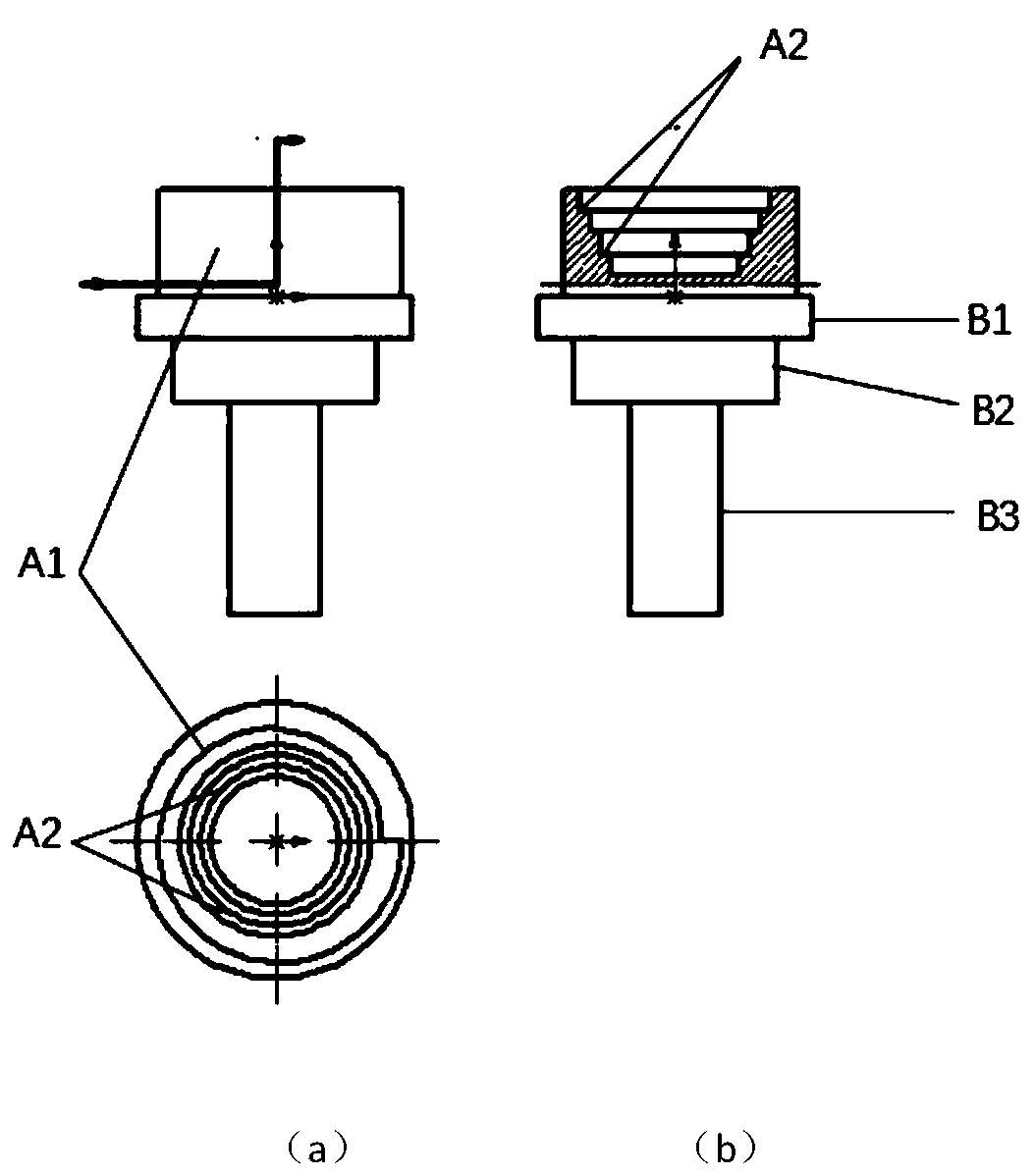

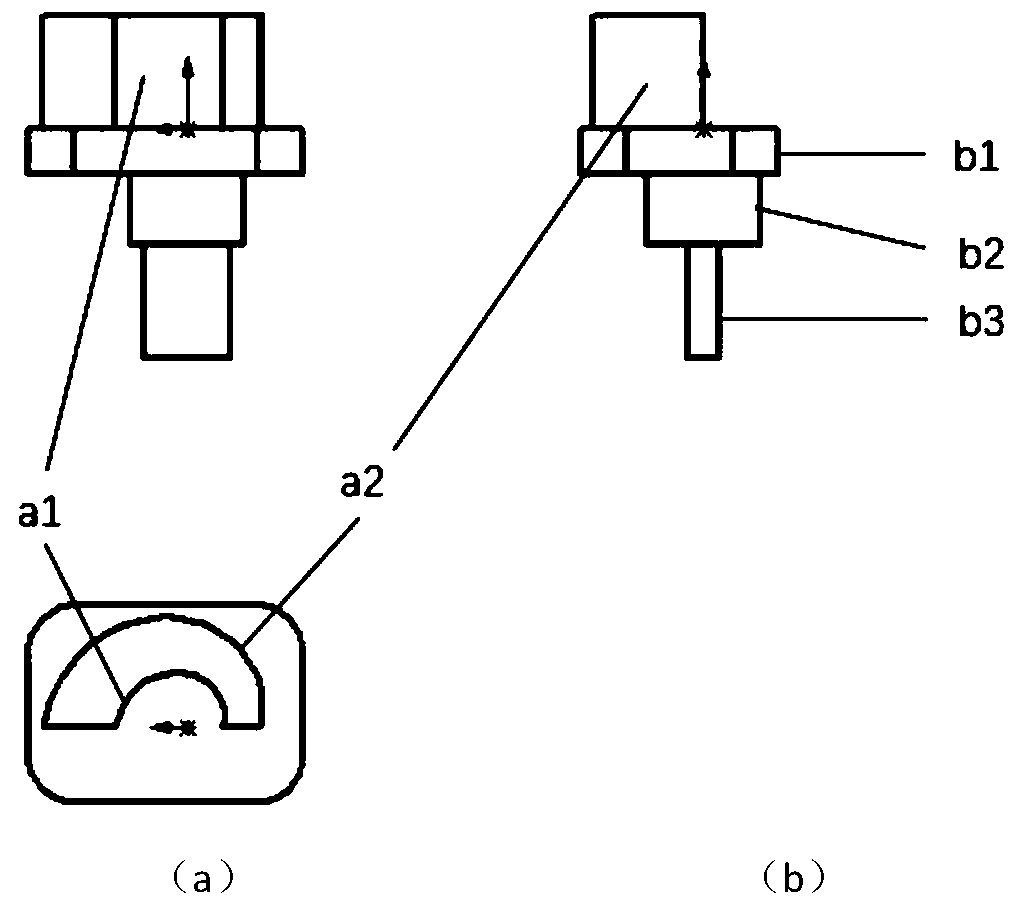

[0039] Phantom one:

[0040] 1) The upper part of the phantom is the measurement structure, the lower part is the auxiliary structure, and the two are directly connected;

[0041] 2) The outer edge of the measurement structure is a cylinder formed by the stretching of an Archimedes spiral, and the inner ring is a circle. The parametric equations in the coordinate system are

[0042]

[0043] Among them, L and S are the length parameters in helical processing, d is the diameter of the inner hole, these three parameters together determine the measurement range of the phantom, θ is the helical rotation angle in radians, and the range is [0, 2π].

[0044] When scanning the measurement structure 360 degrees, the penetration distance x corresponding to the angle θ is

[0045] x=2(L-d)+s*...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com