A dendritic porous sio 2 Base Composite Resin and Its Preparation and Application

A composite resin, dendritic technology, applied in dental preparations, mold cups, dental prostheses, etc., can solve the problems of poor mechanical properties of dental composite resins, and achieve improved mechanical properties, enhanced interfacial adhesion, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Dendritic porous SiO 2 Granule preparation

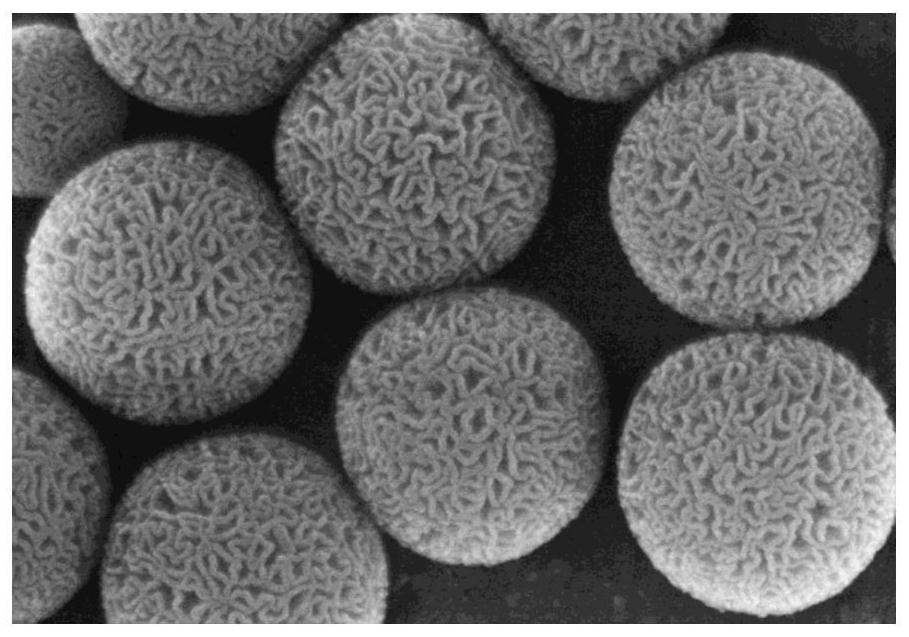

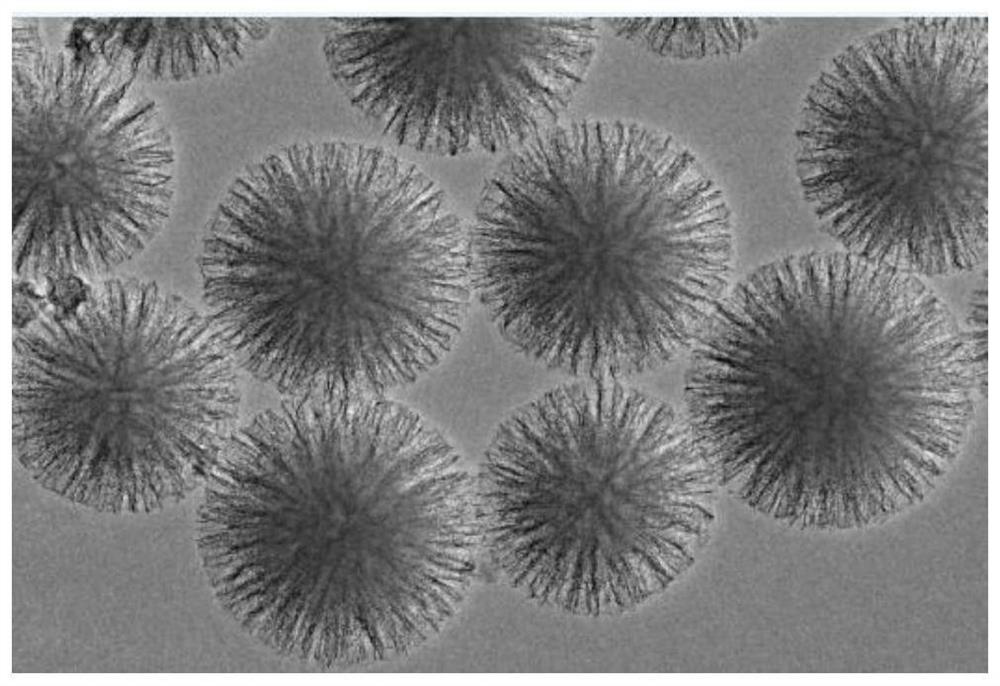

[0039] 1.5ml of pentanol, 15ml of cyclohexane and 1.5ml of tetraethylorthosilicate TEOS were mixed and stirred to form a mixed solution, and then a mixed solution of 1g of CTAB, 0.2g of urea and 10g of water was added to the above mixed solution. Subsequently, the above-mentioned uniformly stirred mixed solution was poured into a polytetrafluoroethylene high-temperature and high-pressure hydrothermal kettle, and reacted at 130°C for 4 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed with acetone and deionized water, and then calcined at high temperature for a certain period of time to obtain Dendritic porous SiO with a particle size of 100 nm 2 Particles, SEM and TEM results were as figure 1 and 2 As shown by the SEM images, it can be concluded that the SiO 2 The particles have a uniform particle size, and the particle surface has a uniformly distributed pore s...

Embodiment 2

[0047] (1) Dendritic porous SiO 2 Granule preparation

[0048] 1.5ml of pentanol, 20ml of cyclohexane and 4.0ml of TEOS were mixed and stirred to form a mixed solution, then a mixed solution of 3g of CTAB, 0.6g of urea and 20g of water was added to the above mixed solution. The above-mentioned uniformly stirred mixed solution is poured into a polytetrafluoroethylene high-temperature and high-pressure hydrothermal kettle, and reacted at 130°C for 4 hours. After the reaction is completed, it is naturally cooled to room temperature, centrifuged, washed with acetone and deionized water, and then calcined at high temperature for a certain period of time to obtain the particle size 300nm dendritic porous SiO 2 particle.

[0049] (2) Preparation of composite resin

[0050] According to the formula shown in Table 2, the above-mentioned dendritic porous SiO 2 The particles, organic monomer and photoinitiator system are mixed. When the inorganic filler is fully wetted by the resin m...

Embodiment 3

[0057] (1) Dendritic porous SiO 2 Granule preparation

[0058] 1.5ml of pentanol, 30ml of cyclohexane and 2.5ml of tetraethylorthosilicate (TEOS) were mixed and stirred into a mixed solution, then a mixed solution of 1.8g of CTAB, 1g of urea and 30g of water was added to the above mixed solution. The above-mentioned uniformly stirred mixed solution is poured into a polytetrafluoroethylene high-temperature and high-pressure hydrothermal kettle, and reacted at 130°C for 4 hours. After the reaction is completed, it is naturally cooled to room temperature, centrifuged, washed with acetone and deionized water, and then calcined at high temperature for a certain period of time to obtain the particle size 500nm dendritic porous SiO 2 particle.

[0059] (2) Preparation of composite resin

[0060] According to the formula shown in Table 3, the above-mentioned dendritic porous SiO with a particle size of 500 nm was firstly mixed by hand 2 The particles, organic monomer and photoinit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com