Descaling and washing equipment for thread rod

A technology for cleaning equipment and threaded rods, which is applied in the electromechanical field, can solve the problems of inconvenient cleaning of dirt, and achieve the effect of improving utilization efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

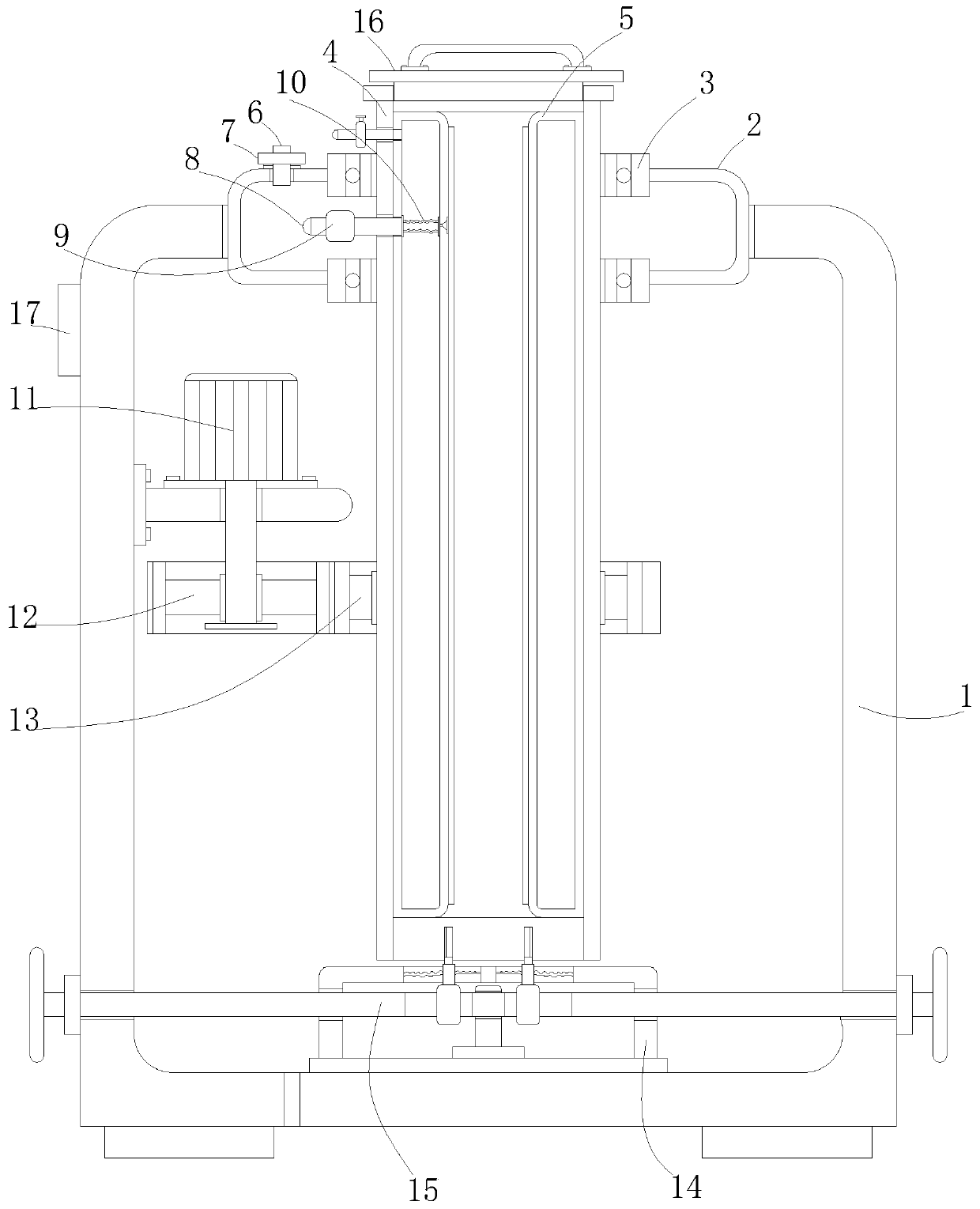

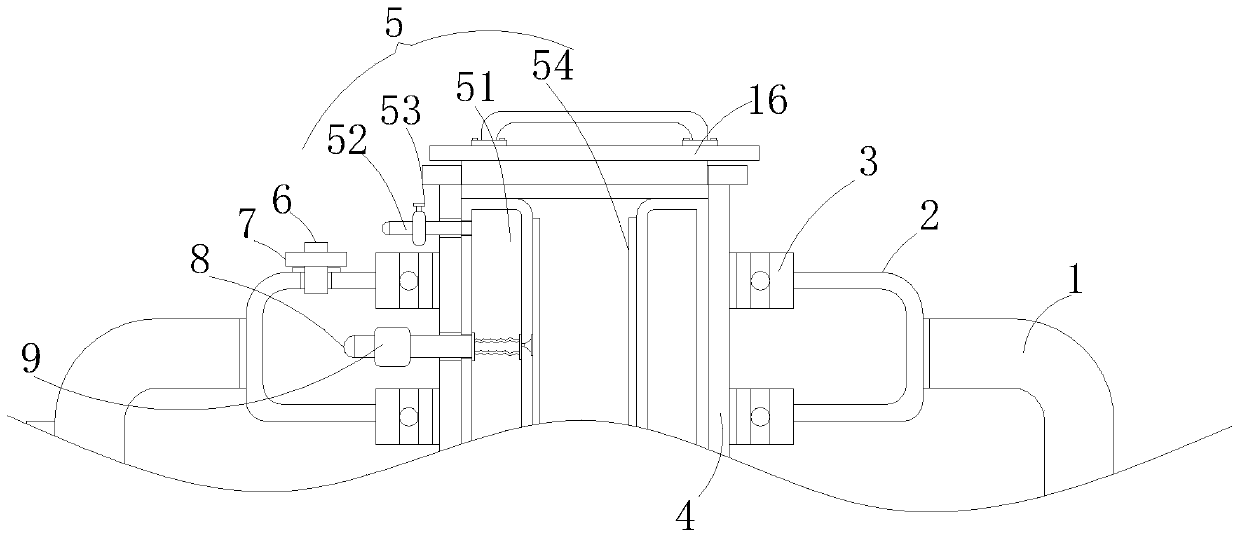

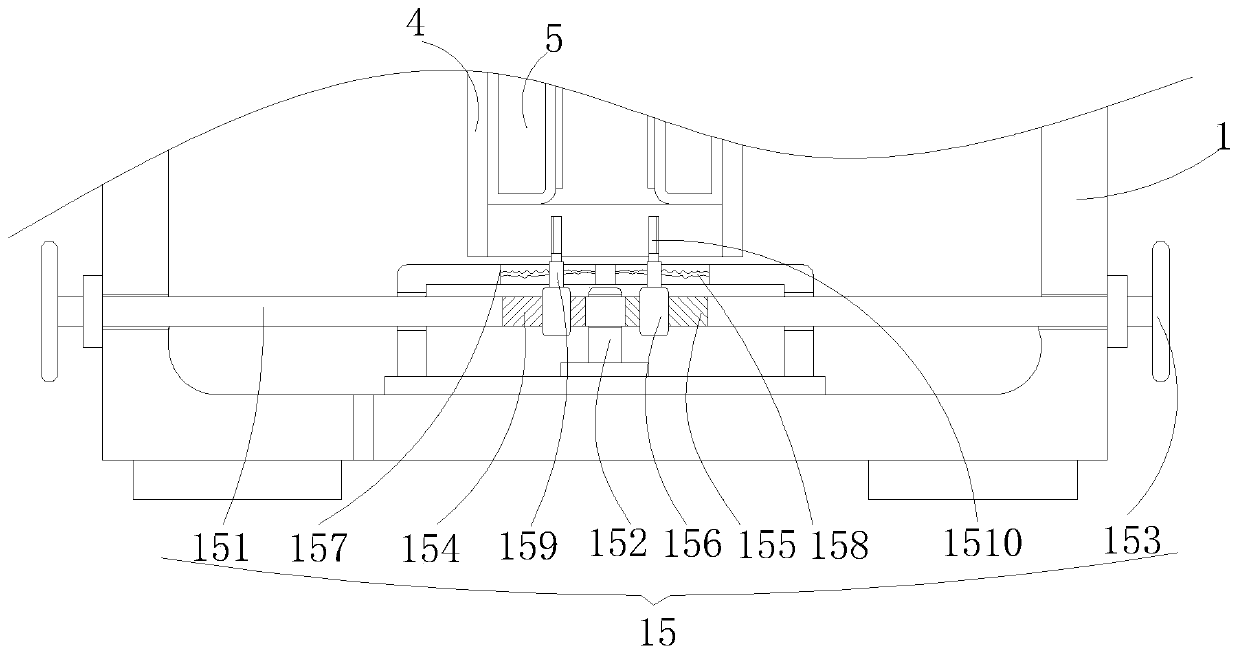

[0020] like Figure 1-4 As shown, the present invention provides a technical solution: a descaling and cleaning equipment for threaded rods, including a body 1, a sealed box 2, two sealed bearings 3, a casing 4, an internal descaling mechanism 5, and a water guide pipe 6 , pressure reducing valve 7, connecting pipe 8, one-way valve 9, telescopic hose 10, driving motor 11, pinion gear 12, large gear 13, isolation frame 14, radial clamping mechanism 15, sealing cover 16 and control switch 17 , the sealing box 2 is installed in the top channel of the body 1, and there are two mounting holes on the sealing box 2, and the two sealed bearings 3 are respectively installed inside the two mounting holes, and the sleeve 4 runs through the two sealed bearings 3 The inner ring of the bearing extends to the inner bottom of the body 1, the inner descaling mechanism 5 is installed on the inner side of the casing 4, the water guide pipe 6 is installed at the water inlet of the sealed box 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com