Full-automatic flange plate circumferential drilling device

A drilling device, a fully automatic technology, applied in the driving device, tangent device, tangent feeding device and other directions, can solve the problem of high manufacturing and maintenance costs, and achieve low manufacturing, maintenance costs, good reliability, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

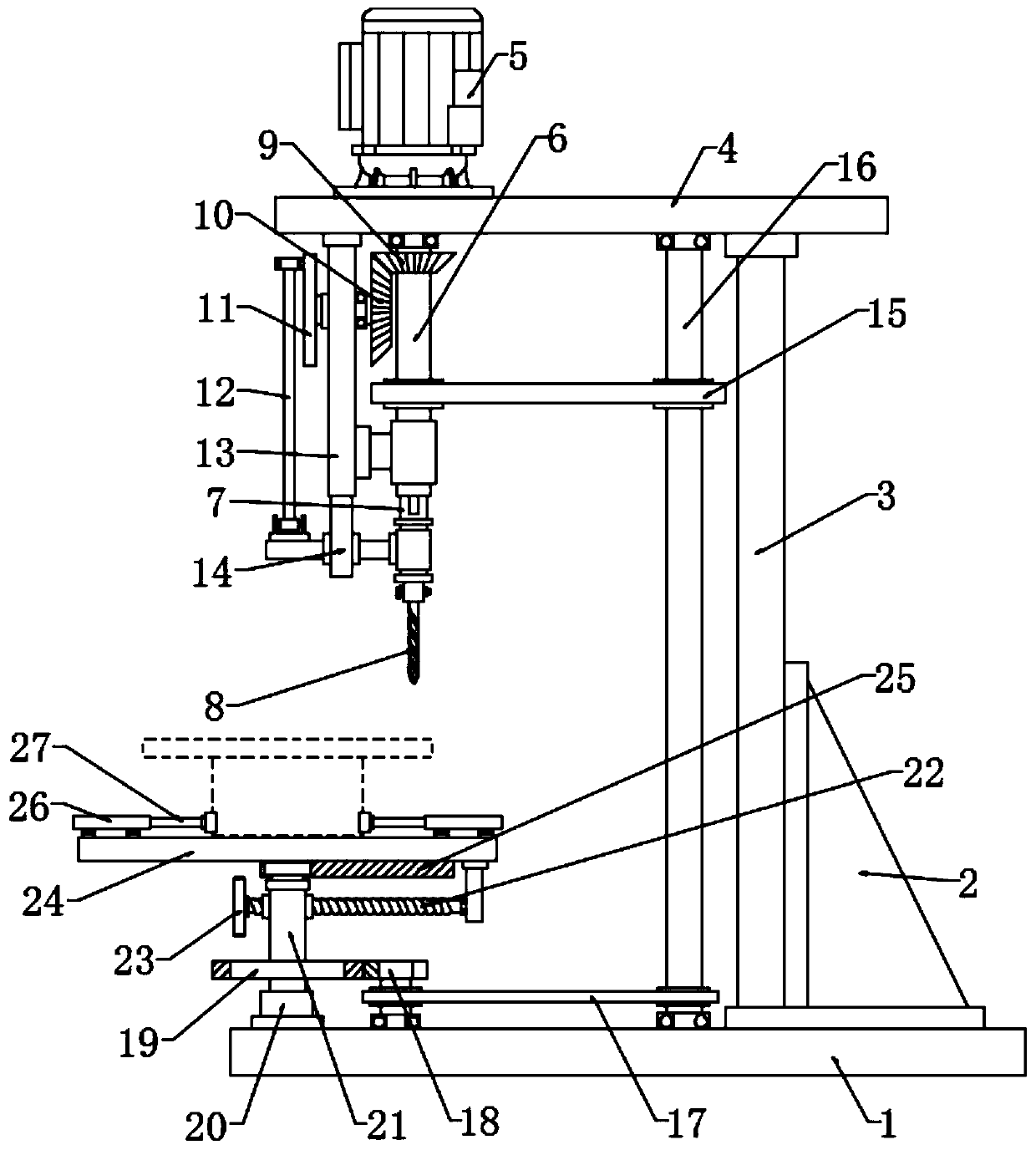

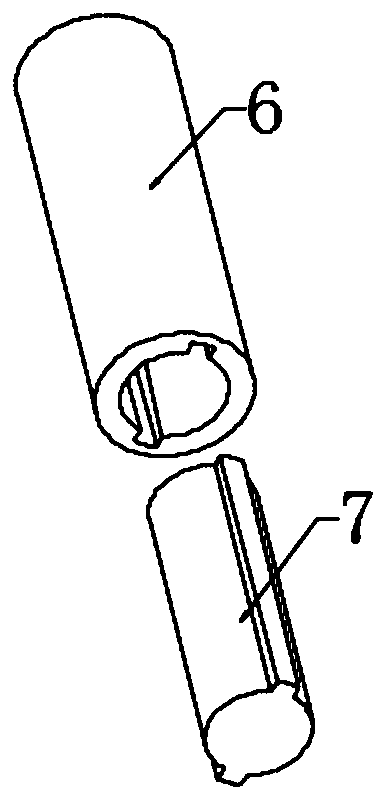

[0023] see Figure 1~4 , in an embodiment of the present invention, a fully automatic flange circumferential drilling device, including a base plate 1, an output shaft 6, a tap 8, a telescopic plate 14 and a platform 24; 3. The upper end of the back plate 3 is fixedly connected to the top plate 4, and the flange on the top plate 4 is connected to the drive motor 5, and the lower part of the drive motor 5 is connected to the output shaft 6 in rotation, and the output shaft 6 passes through the top plate 4 and is connected to the bearing in rotation, wherein the drive motor 5 wires are connected to the power supply and the switch, and the switch is turned on so that the drive motor 5 is powered on and energized to drive the output shaft 6 to rotate; the lower part of the output shaft 6 is socketed with the driven shaft 7, specifically, the output shaft 6 is hollow, and the inner wall of the output shaft 6 is hollow. Two grooves are symmetrically arranged, and the outer surface o...

Embodiment 2

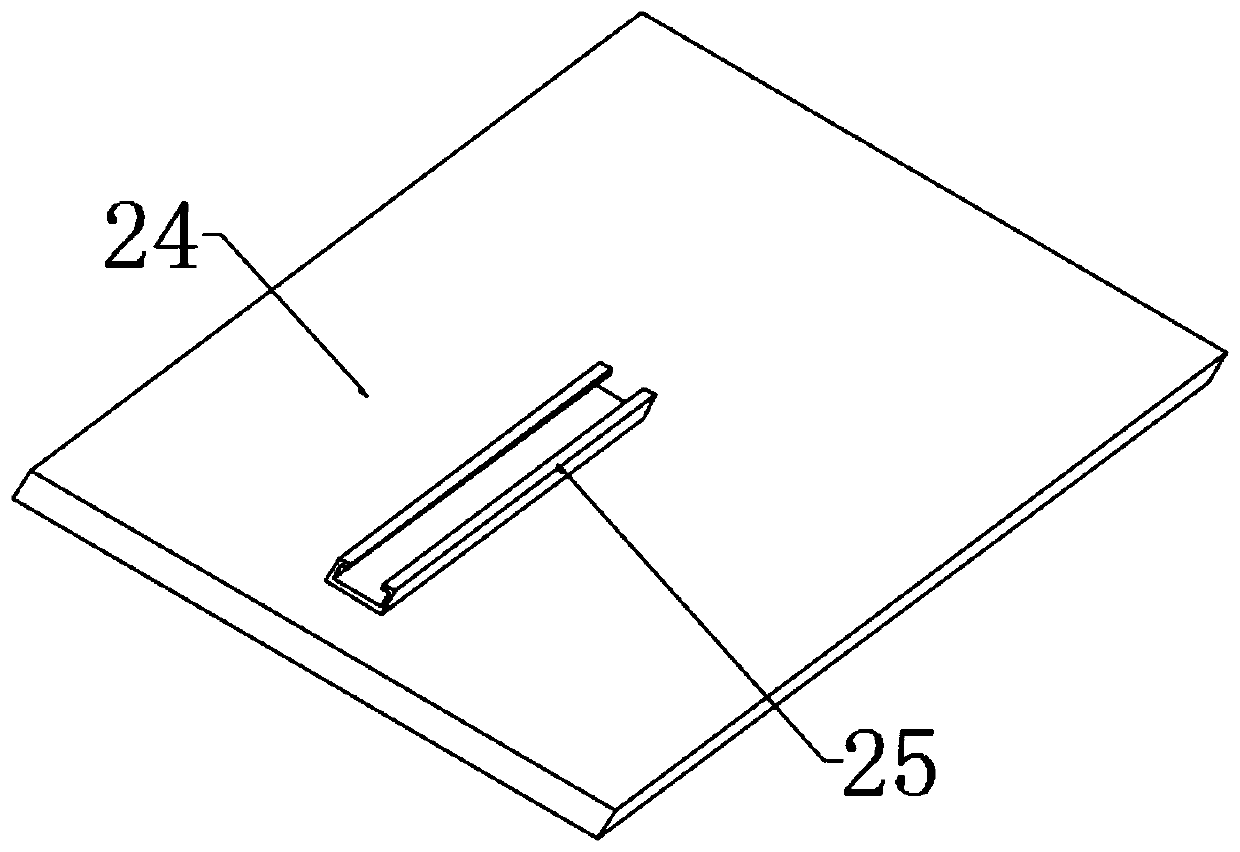

[0027] In order to further explain the above-mentioned fully automatic flange circumferential drilling device, the application provides another embodiment, the fully automatic flange circumferential drilling device in this embodiment has the following technical features: the platform 24 Cylinders 26 are symmetrically fixed on both sides of the upper side, and one side of the cylinder 26 is sealed and slidably connected to the piston rod 27. The end of the piston rod 27 is fixed with a clamp 28. The clamp 28 is arc-shaped. The thinner part of the lower part of the flange is clamped to prevent the flange from moving when drilling.

[0028]According to the specific description of the above embodiments, it is easy to know that the working principle of the present invention is: turn on the switch to make the drive motor 5 turn on the power and work to drive the output shaft 6 to rotate, and the output shaft 6 can drive the driven shaft through the cooperation of the convex strip and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com