Method for mounting positive displacement metering pump in working position

A working position, metering pump technology, applied in the direction of variable volume pump components, components of pumping devices for elastic fluids, liquid variable volume machinery, etc., to achieve the effects of avoiding damage, fast fixing, and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

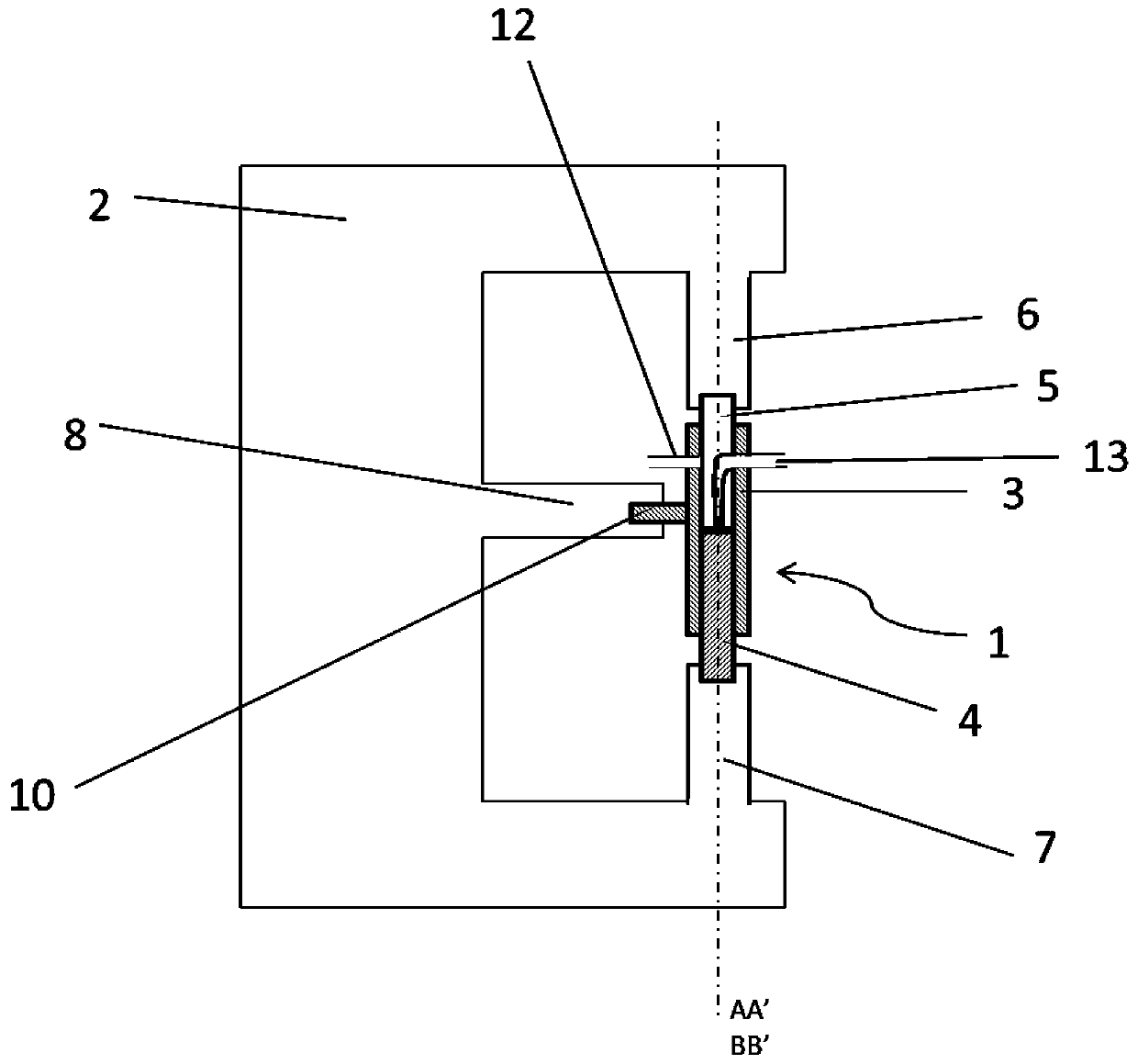

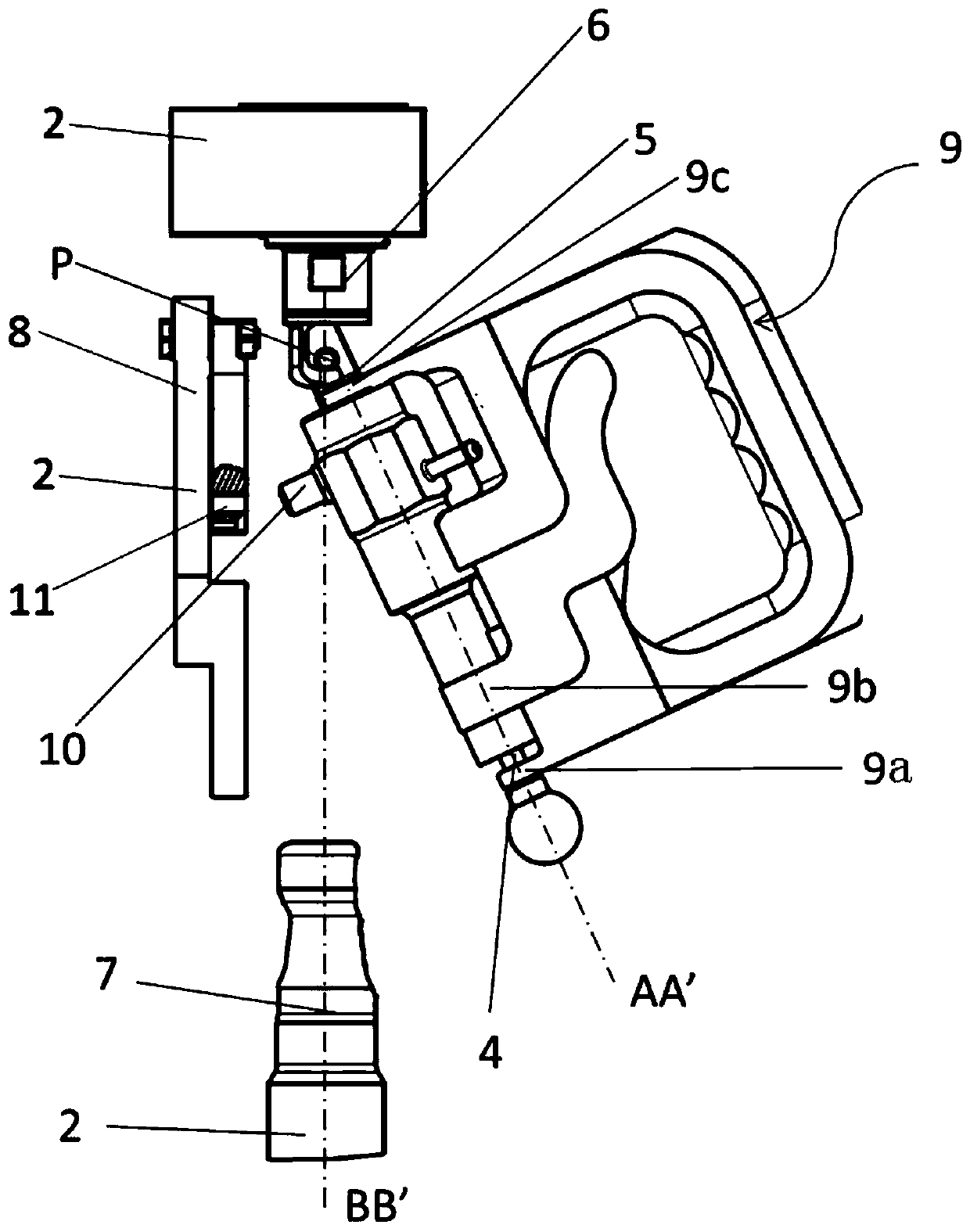

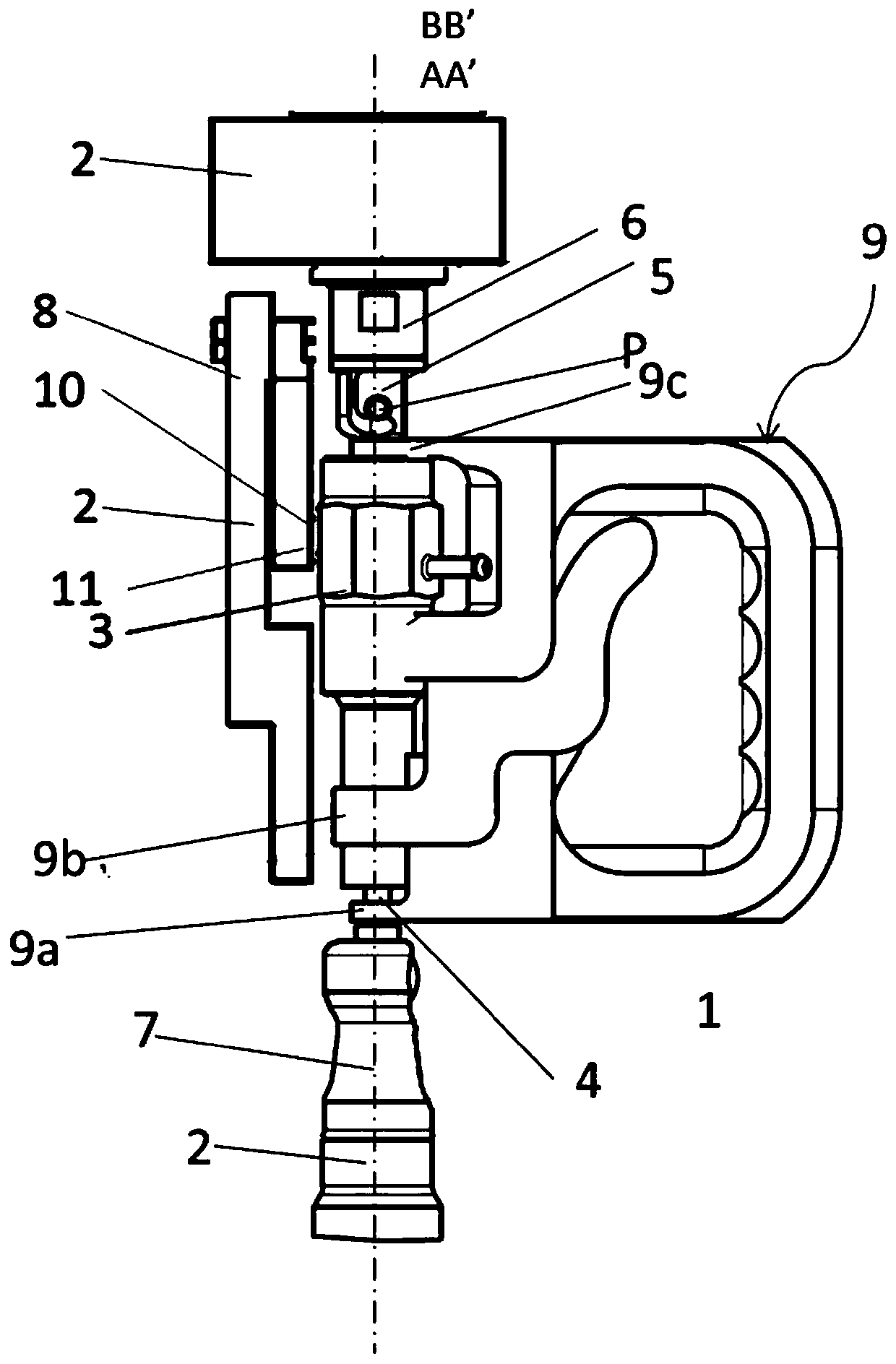

[0059] Such as figure 1 As shown, the principle of interconnection of the positive displacement metering pump 1 in the working position with the drive machine 2 is illustrated. The drive machine 2 comprises two arms, a second arm 6 and a first arm 7 , and a stationary body 8 . A positive displacement metering pump 1 comprises a hollow cylindrical pump body 3, a fluid inlet 12 and a fluid outlet 13, wherein a piston 4 is slidably mounted in the hollow cylindrical pump body 3 along the pump axis AA' and rotates around the pump axis AA' A switching valve 5 is installed. The piston 4 and the switching valve 5 are generally cylindrical matched with the inside of the pump body 3 . The piston 4 and the switching valve 5 protrude from one side of the pump body 3 respectively. The sleeve 10 protrudes from the side of the pump body 3 .

[0060] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com