Tool wear condition prediction method of numerical control machine tool based on parallel deep neural network

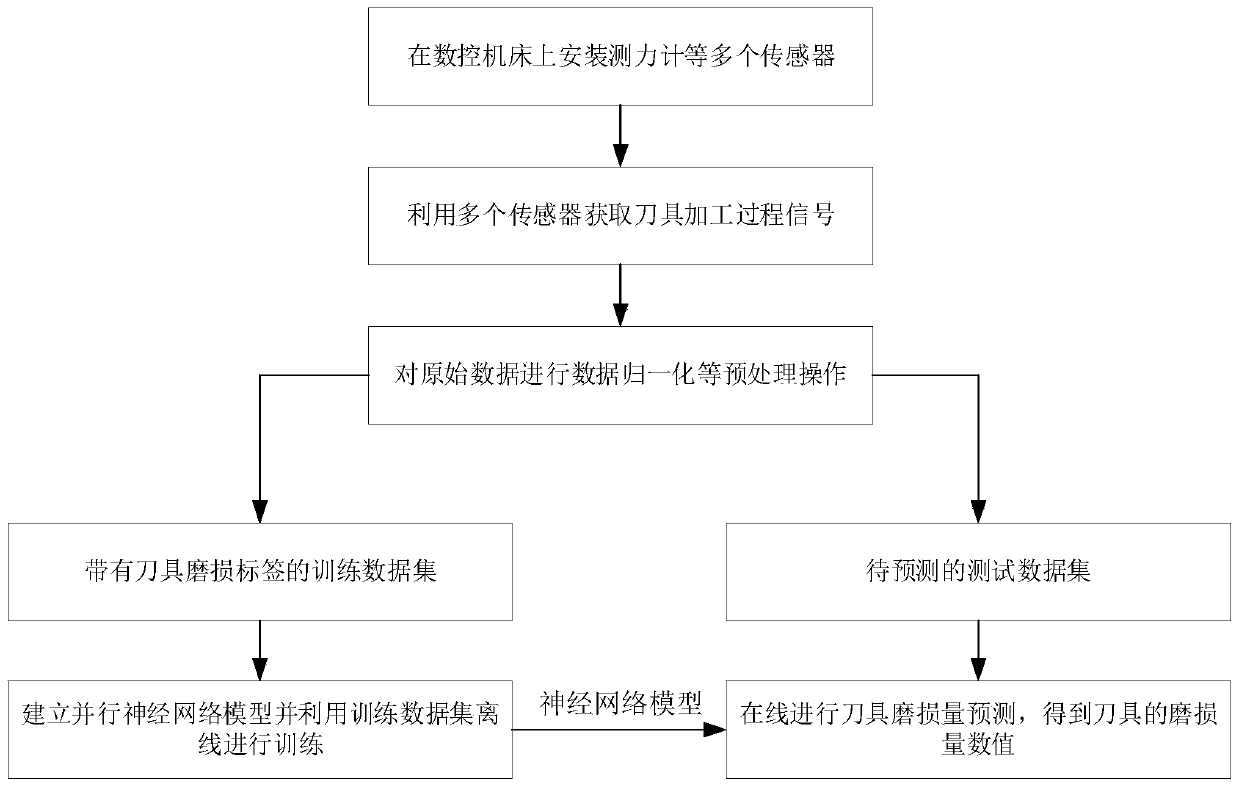

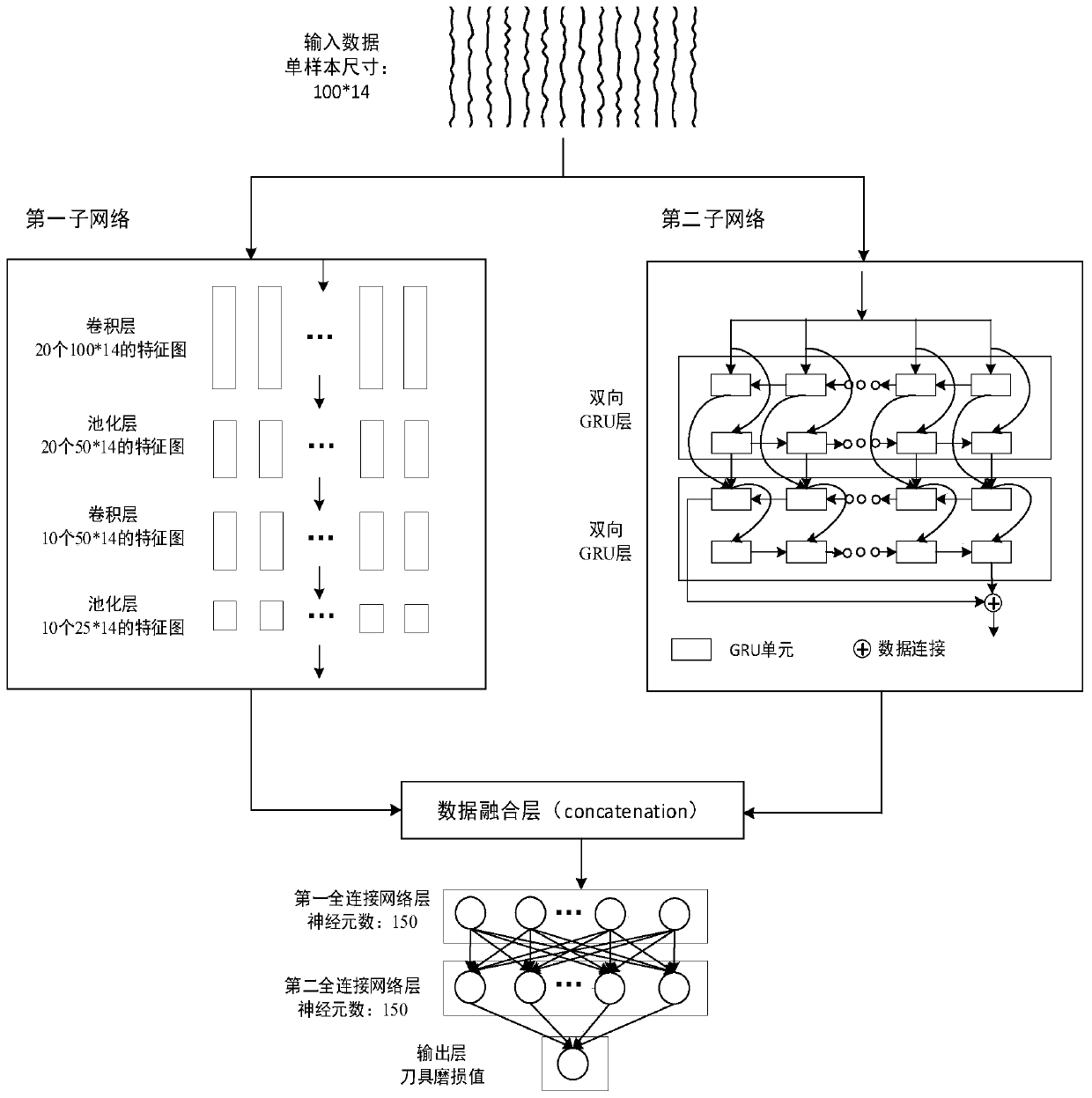

A deep neural network and tool wear technology, which is used in the prediction of tool wear state of CNC machine tools, and the field of tool wear state prediction of CNC machine tools based on parallel neural networks, can solve the problems of limited application, low prediction accuracy and weak data processing ability. and other problems, to achieve the effect of wide applicability and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0052] The International PHM (Fault Diagnosis and Health Management) Data Competition is a competition with great influence on fault prediction. This example uses the competition data of the 2010 International PHM Data Competition to verify the effectiveness of the proposed method.

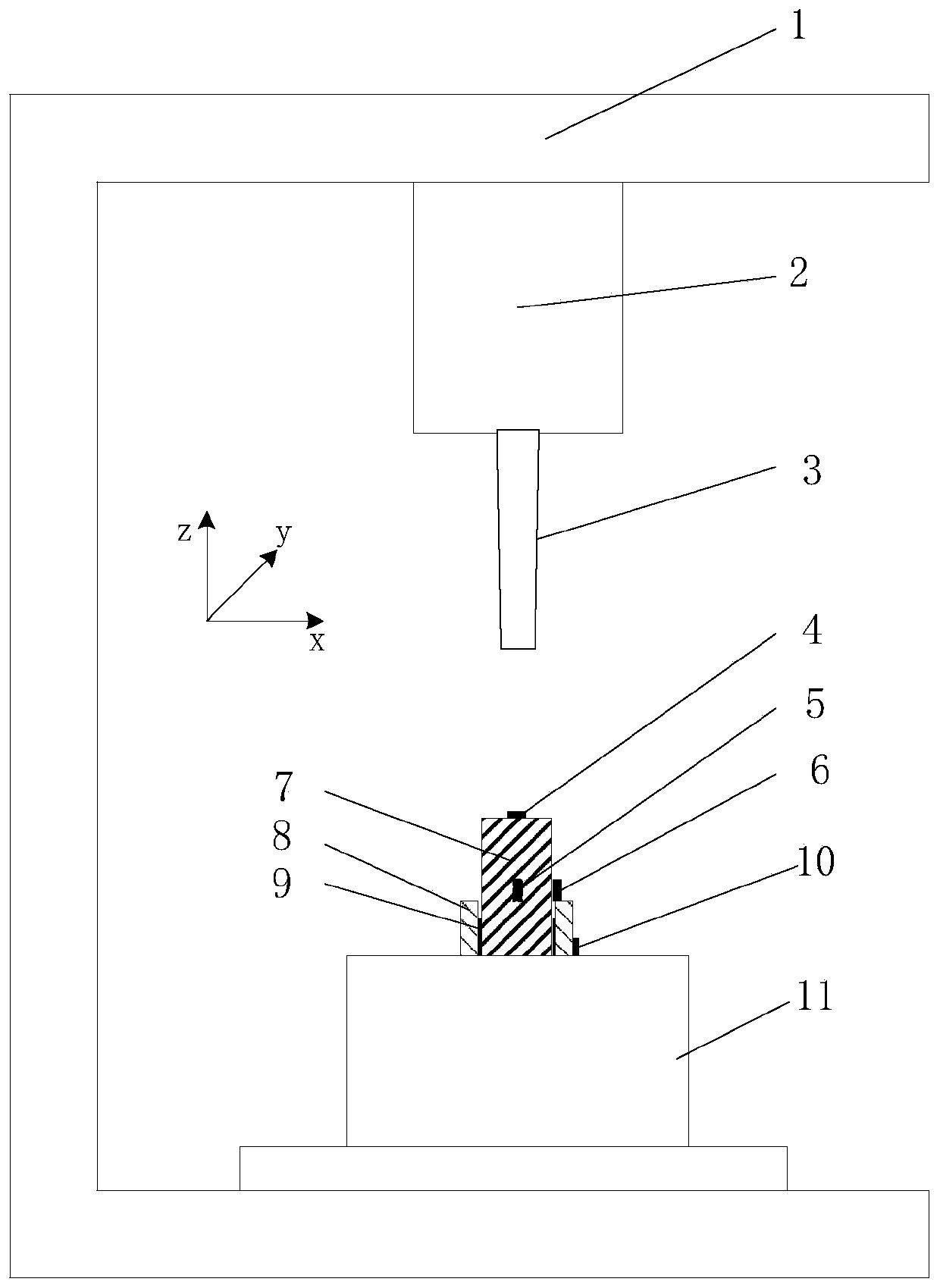

[0053] The specific implementation of CNC machine tools such as figure 2 As shown, the spindle 2 of the CNC machine tool 1 is located above the workpiece 7, the workpiece 7 is clamped in the fixture 8, the fixture 8 is fixed on the worktable 11, and three acceleration sensors 4, 4 and 4 are embedded in the three directions of the workpiece 9. 5, 6. The three-component force gauge 9 is installed between the workpiece 7 and the fixture 8, and the acoustic sensor 10 is embedded on the fixture 8.

[0054] The collected data includes: x-axis cutting force, y-axis cutting force, z-axis cutting force, x-axis vibration, y-axis vibration, z-axis vibration and sound signal. The basic process parameters se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com