Scissors

A scissors and through-hole technology, applied in metal processing and other directions, can solve the problems of high price and complex structure, and achieve the effects of good sharpness, restraint of wear, and reduced force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] for the manner in which the invention is carried out

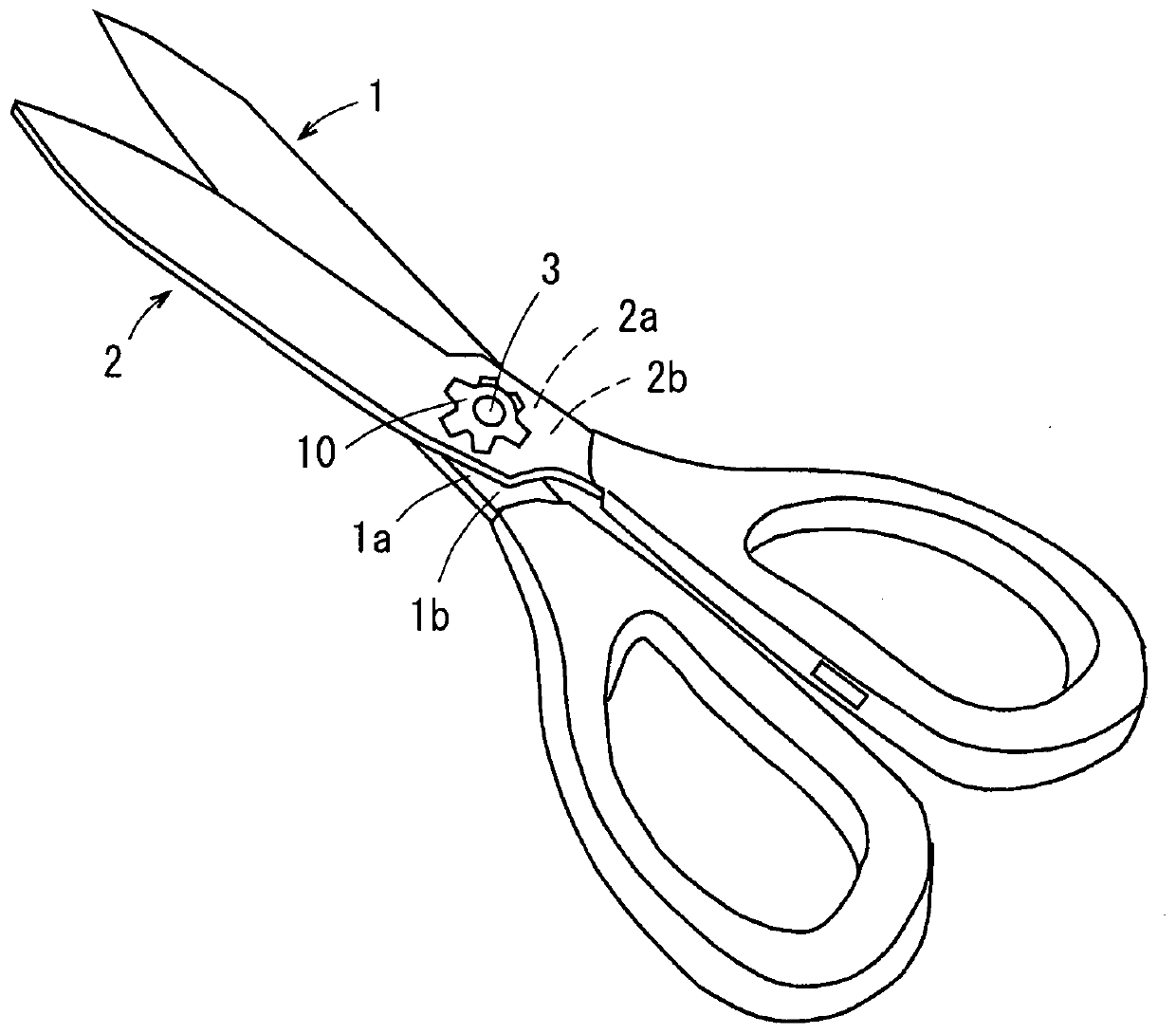

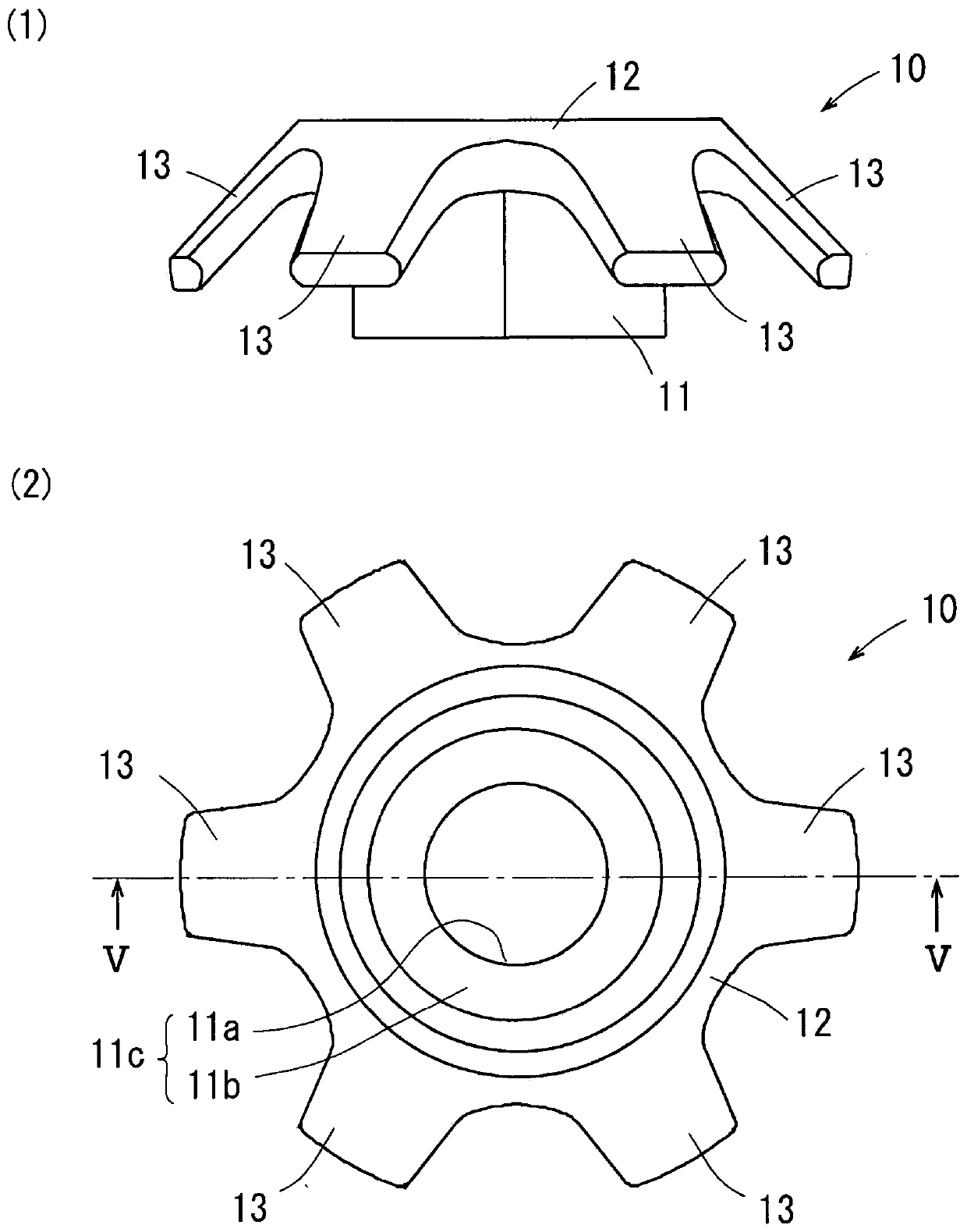

[0066] Embodiments 1 to 4 in which scissors according to the present invention are embodied will be described below based on the drawings. First, scissors according to Embodiment 1 will be described. figure 1 It is an assembled perspective view of the scissors of Embodiment 1, figure 2 This is an exploded perspective view of the scissors. like figure 1 , 2 As shown, this scissors will be the first blade body 1 as the static blade and the second blade body 2 as the moving blade by the first and second main parts 1a, 2a that will be located in the central part of the first and second blade bodies 1, 2. The penetrating rivet 3 as the main shaft is connected so as to be openable and closable. The rivet 3 is composed of a columnar main body 3 a and a frustoconical head 3 b formed at the proximal end of the main body 3 a. In addition, a resin elastic member 10 is interposed between the second blade body 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com