Automatic pattern cutting equipment

A cutting flower and equipment technology, applied in metal processing, slaughtering, poultry processing, etc., can solve the problems of high labor cost and low work efficiency, and achieve the effect of reducing labor cost, improving work efficiency and reducing space occupancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

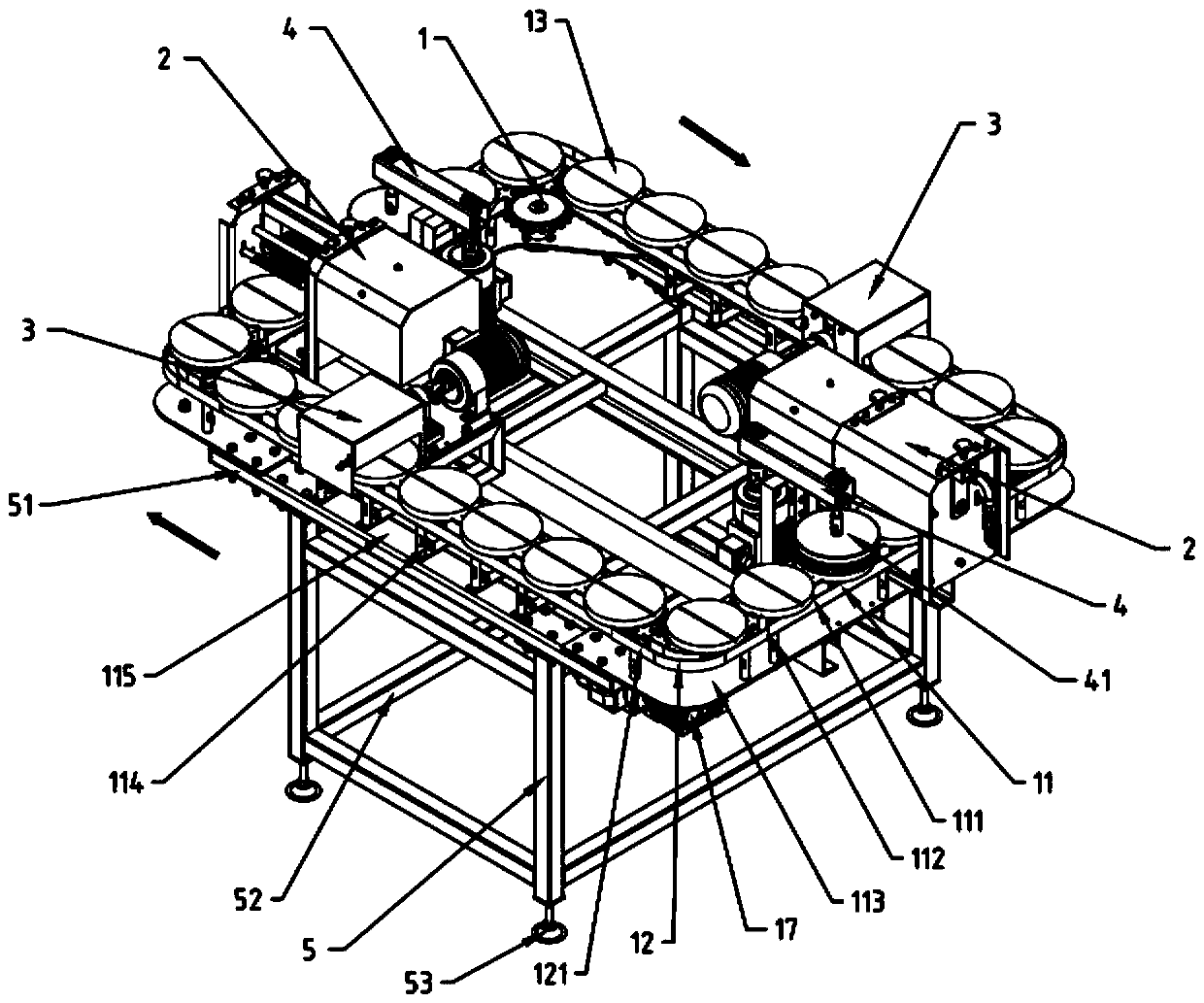

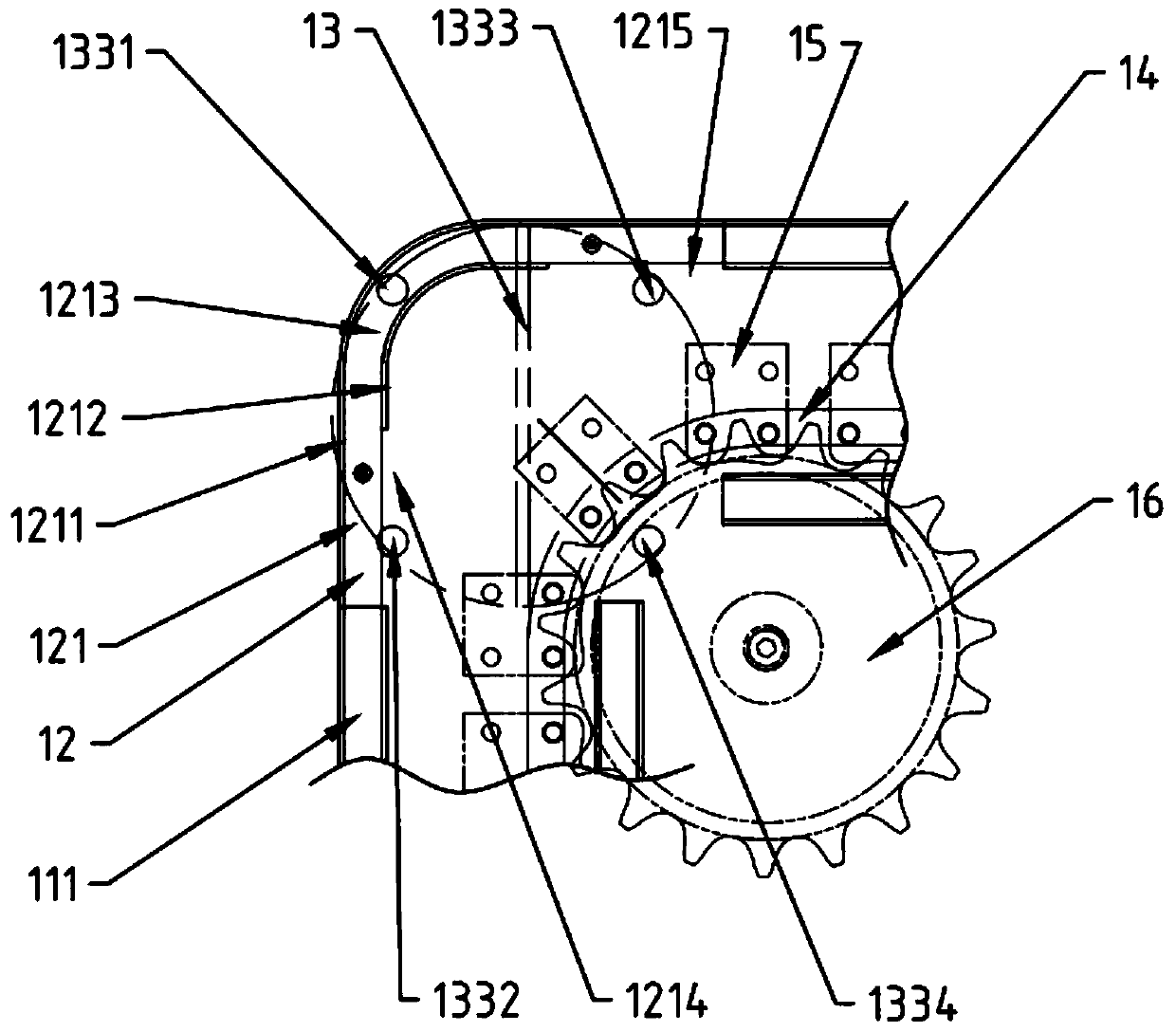

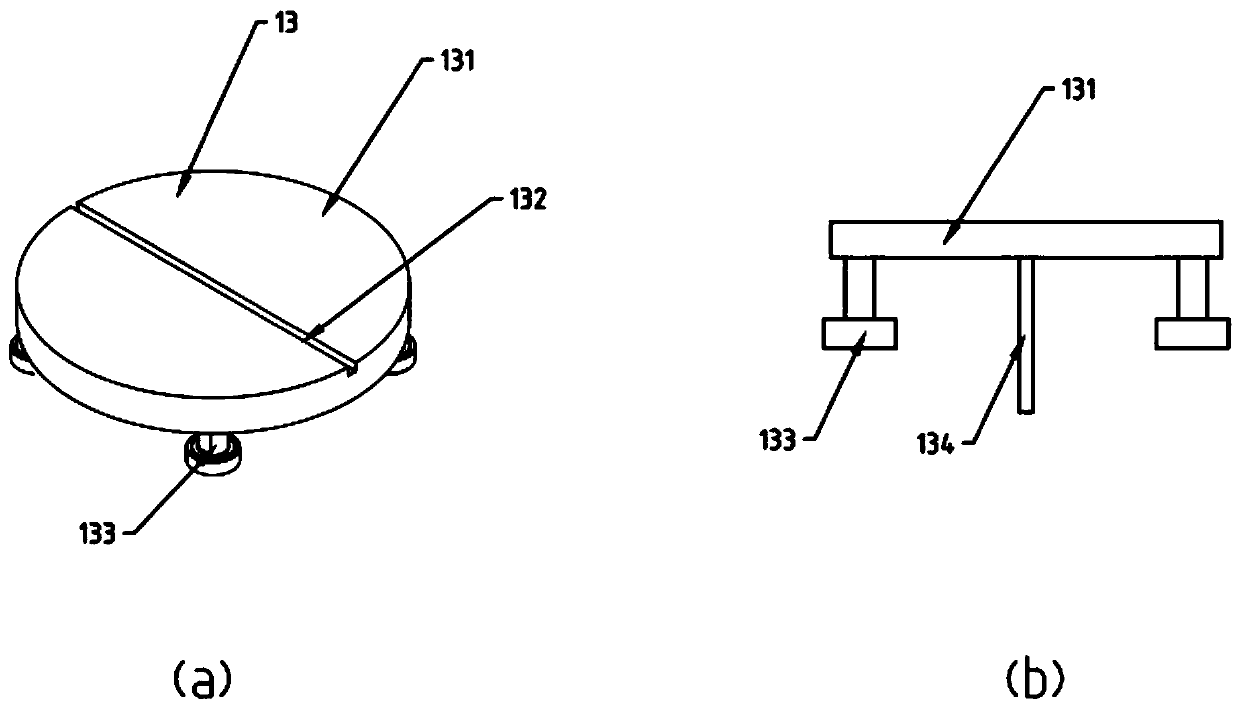

[0030] see figure 1 , figure 1 It is a kind of automatic cut flower equipment of this embodiment, including a transmission mechanism 1, a cut flower assembly 2, a half-cut assembly 3, a sweep-out assembly 4 and a support assembly 5, and the support assembly 5 supports the above-mentioned transmission mechanism 1, cut flower assembly 2, The half-cut assembly 3 and the sweep-out assembly 4, the conveying mechanism 1 includes a first conveying mechanism 11 and a second conveying mechanism 12, wherein the first conveying mechanism 11 is a linear conveying mechanism, and the second conveying mechanism 12 is a curved conveying mechanism , the conveying mechanism 1 is a closed loop composed of several first conveying mechanisms 11 and several second conveying mechanisms 12, and several product fixing components 13 are distributed on the first conveying mechanism 11 and the second conveying mechanism 12, and the product is fixed The component 13 can move circularly on the conveying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com