Reinforcing steel bar binding moulding bed frame for prefabricating T-beam wing plate and use method

A technology of steel bar binding and beam wing plate, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems affecting T-beam pouring, bellows are easy to shift, T-beam binding wing plate takes a long time, etc., to improve work efficiency and Quality of work, simple structure, time-consuming effects to solve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

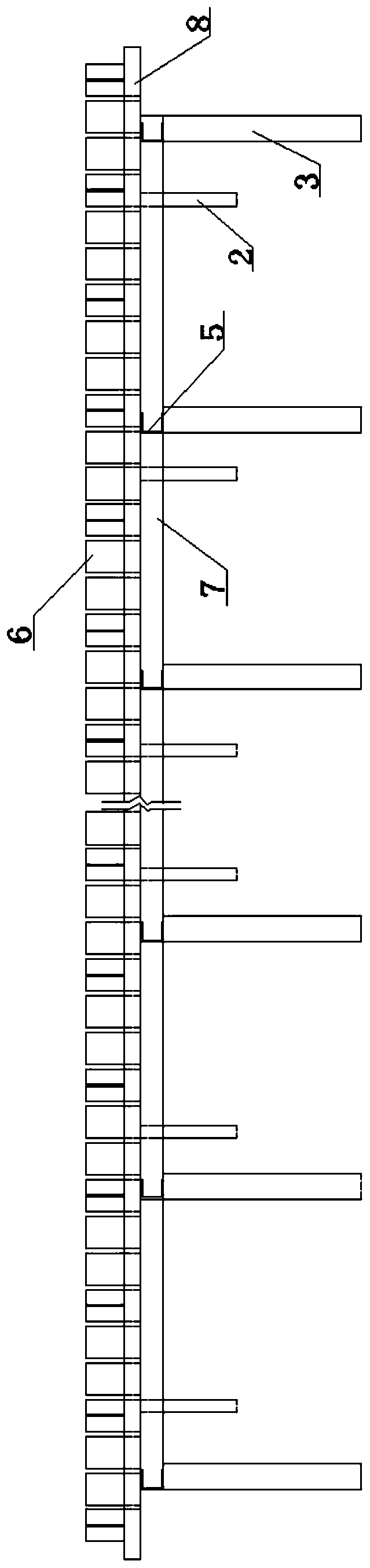

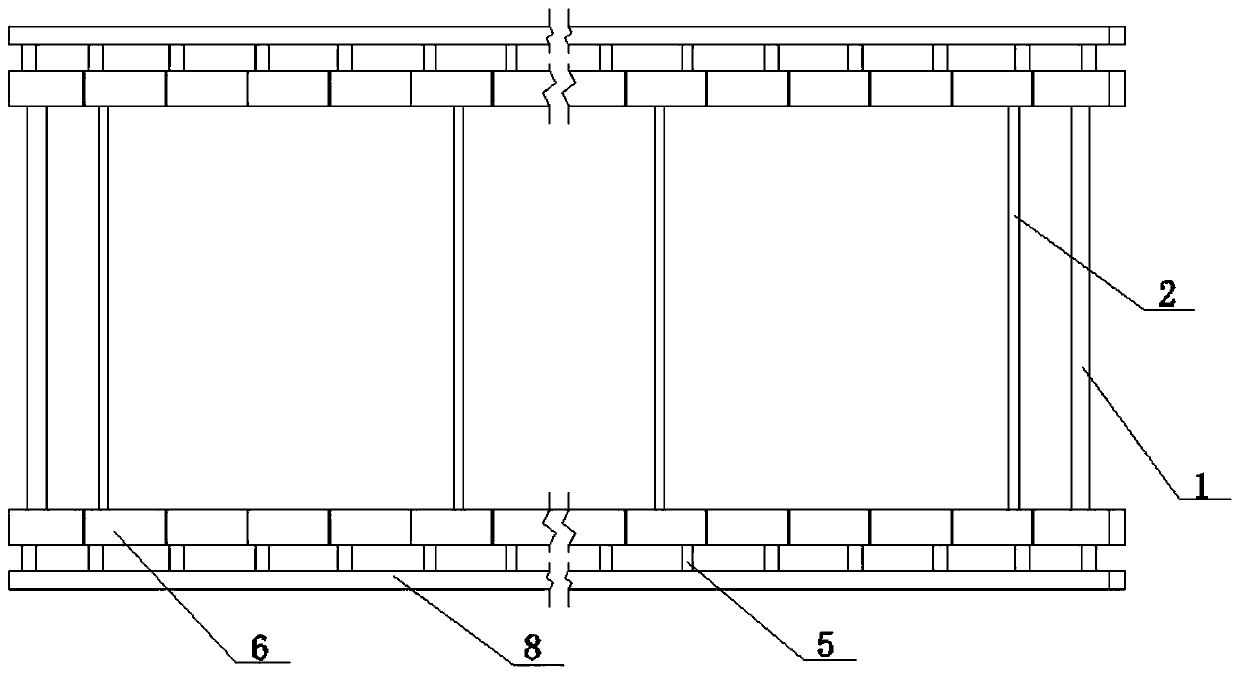

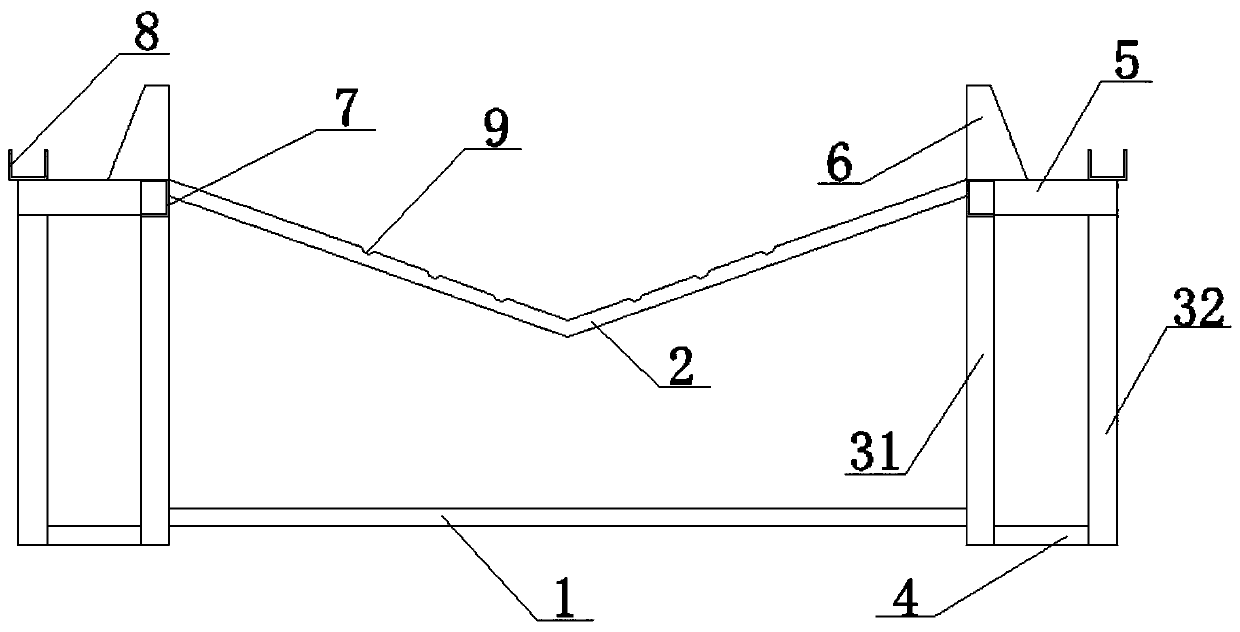

[0036] As attached to the manual Figures 1 to 4 The shown prefabricated T-beam wing plate steel bar binding tire formwork includes a plurality of connecting rods 1 arranged in parallel, each connecting rod 1 is provided with two main poles 3 at both ends, and the two main poles 3 includes the first main pole 31 and the second main pole 32, the two ends of the connecting rod 1 are welded with the first main pole 31, and the top ends of the first main pole 31 at both ends of the connecting rod 1 are welded respectively There is a main beam 7, and a plurality of V-shaped brackets 2 are welded equidistantly between the main beams 7 on the same side. The upper surface of the V-shaped bracket 2 is provided with a plurality of bellows positioning grooves 9, and the main beam 7 on the same side is far away from the The surface of the side wall of the V-shaped bracket 2 is equidistantly welded with a plurality of upper fixing rods 5, and the upper surface of the upper fixing rod 5 awa...

Embodiment 2

[0044] A method for using a steel bar binding tire formwork for prefabricating a T-beam wing plate, comprising the following specific implementation steps:

[0045] Step 1: Set up the reinforcing bars for positioning, and insert the two rows of reinforcing bars for positioning into the ground at the designated position at a certain interval;

[0046] Step 2, the first main pole 31 and the second main pole 32 are welded with reinforcing bars for positioning;

[0047] Step 3, the lower fixed rod 4 and the upper fixed rod 5 are respectively connected to the first main vertical rod 31 and the second main vertical rod 32 for horizontal welding and fixing, and the lower fixed rod 4 is welded to the steel bar for positioning;

[0048] Step 4, use connecting rod 1 to connect below the first main poles 31 in two horizontal rows;

[0049] Step 5, use the main crossbeam 7 to connect above the first vertical main pole 31 of each row;

[0050] Step 6, multiple V-shaped brackets 2 are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com