Automatic flow line type UV curing equipment

A curing equipment, streamlined technology, applied in the direction of conveyor objects, conveyors, devices for coating liquid on the surface, etc., can solve the problem of low assembly accuracy and stability, unfavorable product quality assurance, low production efficiency, etc. problems, to achieve the effect of facilitating real-time adjustment and review, consistent curing effect, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

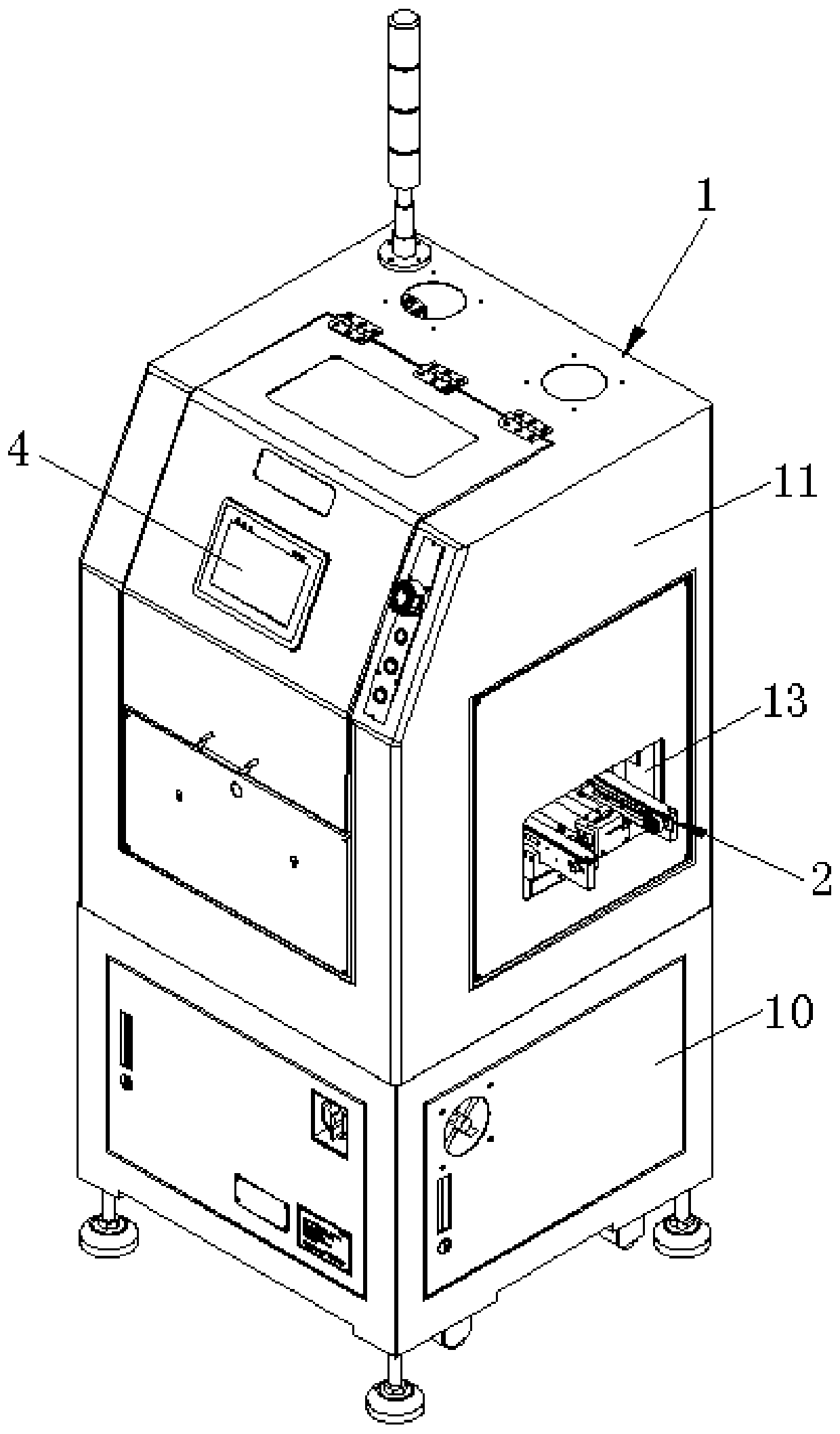

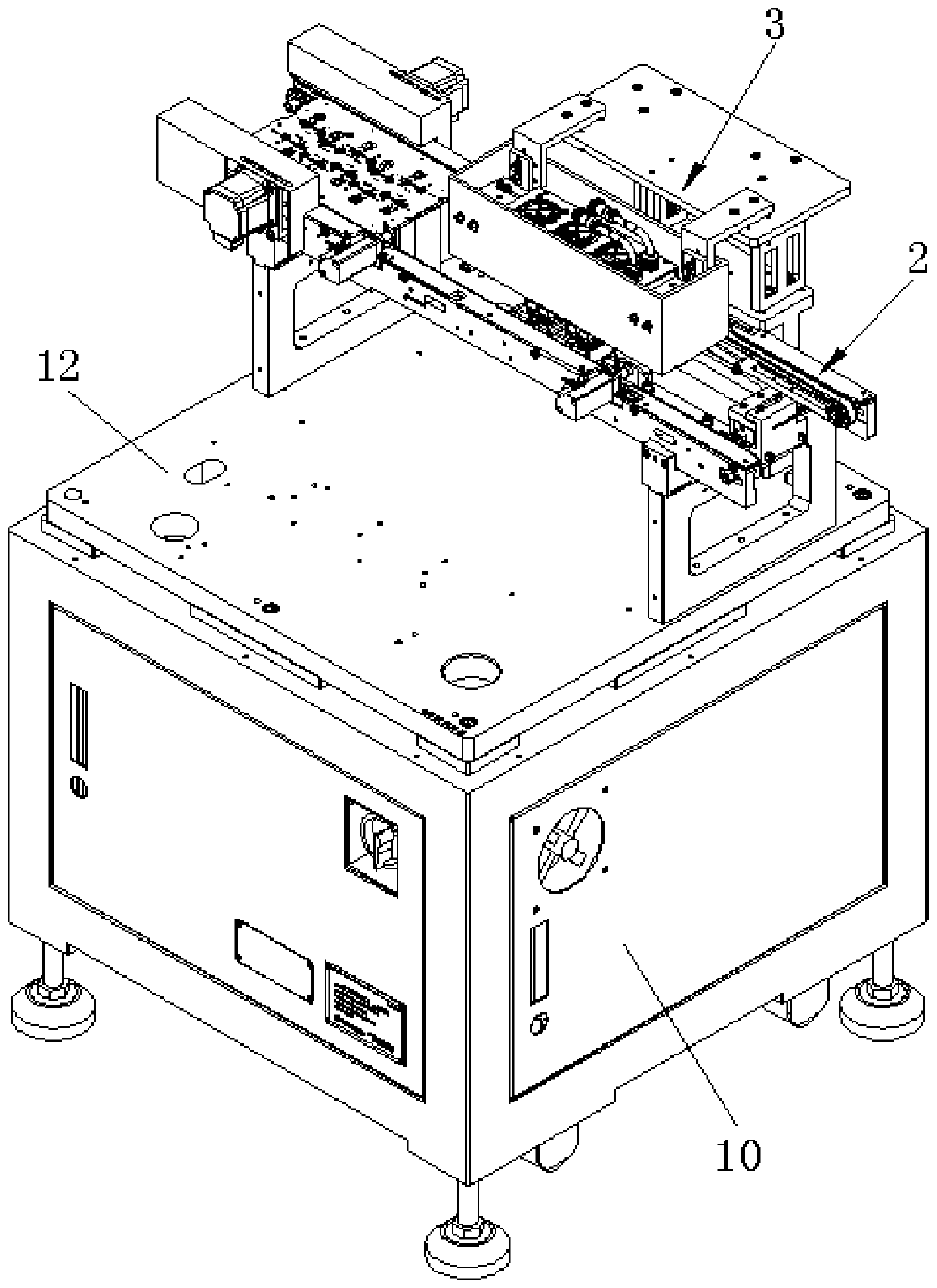

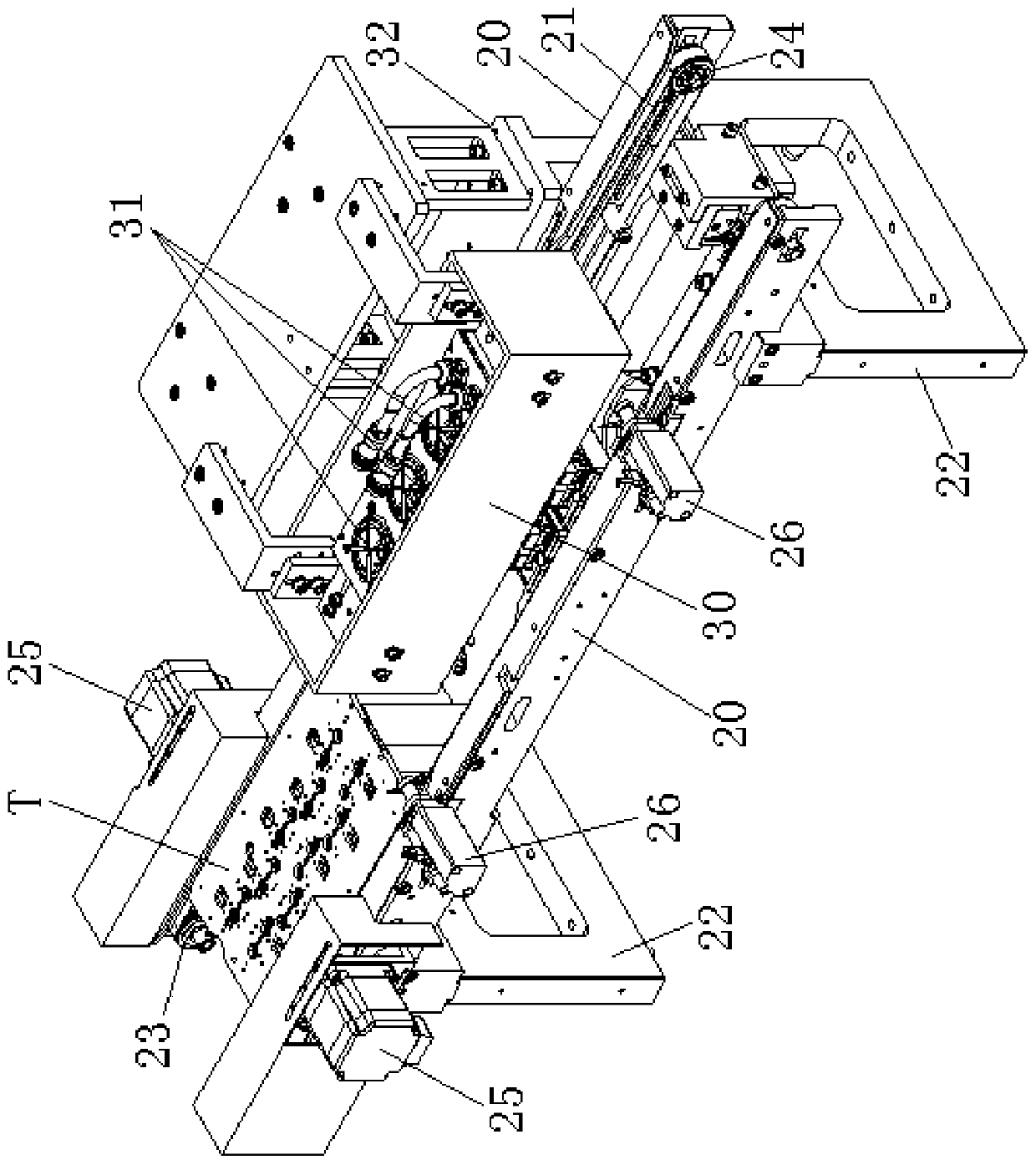

[0038] See attached figure 1 And figure 2 Shown are the three-dimensional schematic diagram of the automatic streamline UV curing equipment of the present invention and the schematic diagram of the assembly structure in which the conveyor line device and the UV light box are assembled together on the chassis shell.

[0039] The automatic streamlined UV curing equipment of the present invention is used to perform UV curing treatment on a number of product RAMs placed on the carrier tray T; the UV curing equipment includes a cabinet casing 1, a conveyor line device 2 capable of conveying the carrier tray , And UV light box 3, wherein a processing space is formed inside the cabinet shell 1, the conveying line device 2 is installed in the processing space, and the feeding side and the discharging side of the conveying line device 2 are also They are all worn out of the chassis shell 1 to connect with external feeding equipment and unloading equipment respectively; the UV light box 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com