Adhesive tape unwinding and cut-off device

A technology of cutting device and tape, applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of affecting work efficiency, inconvenience, waste of physical strength, etc., to save labor, facilitate disassembly, and improve design rationality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

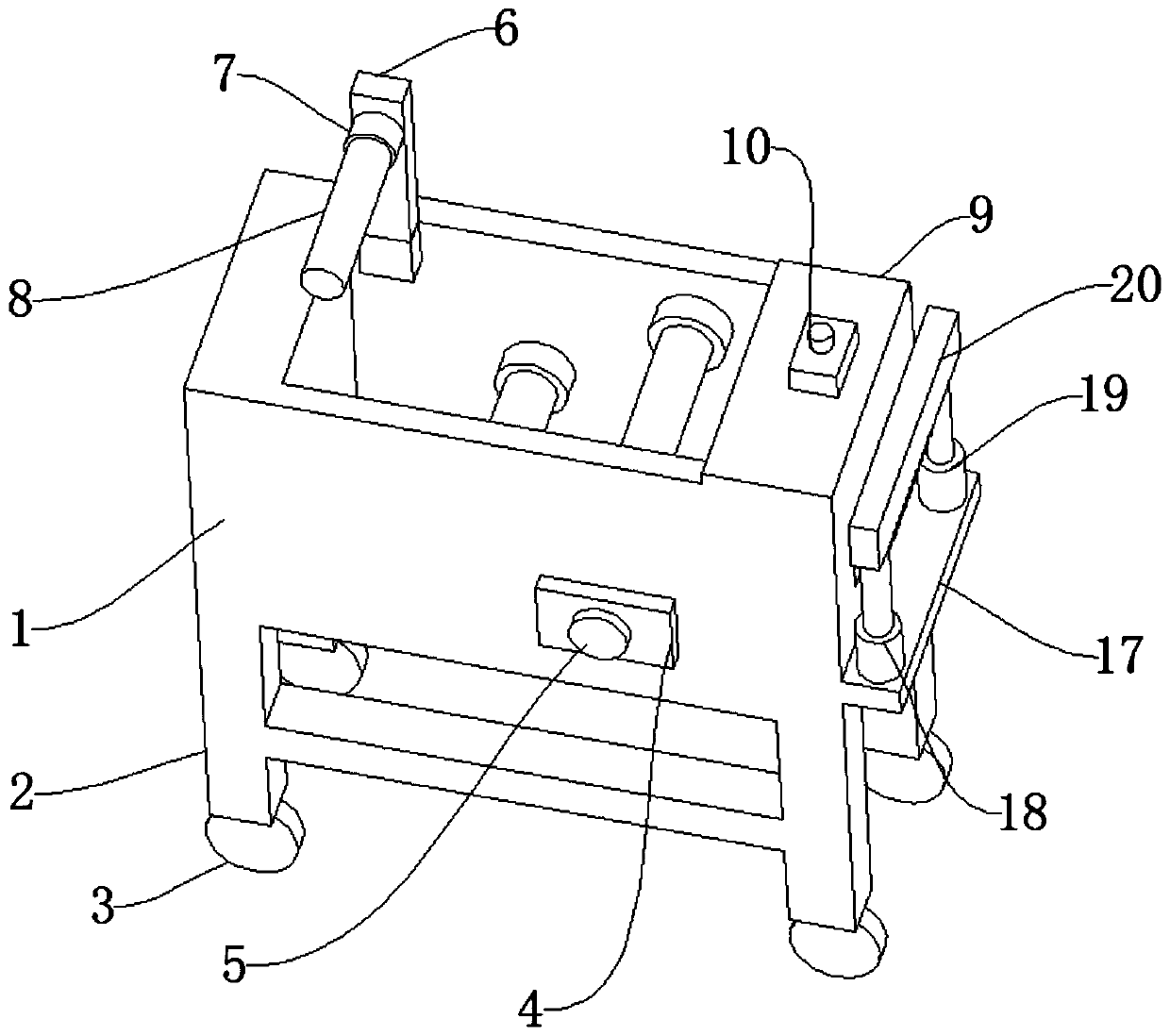

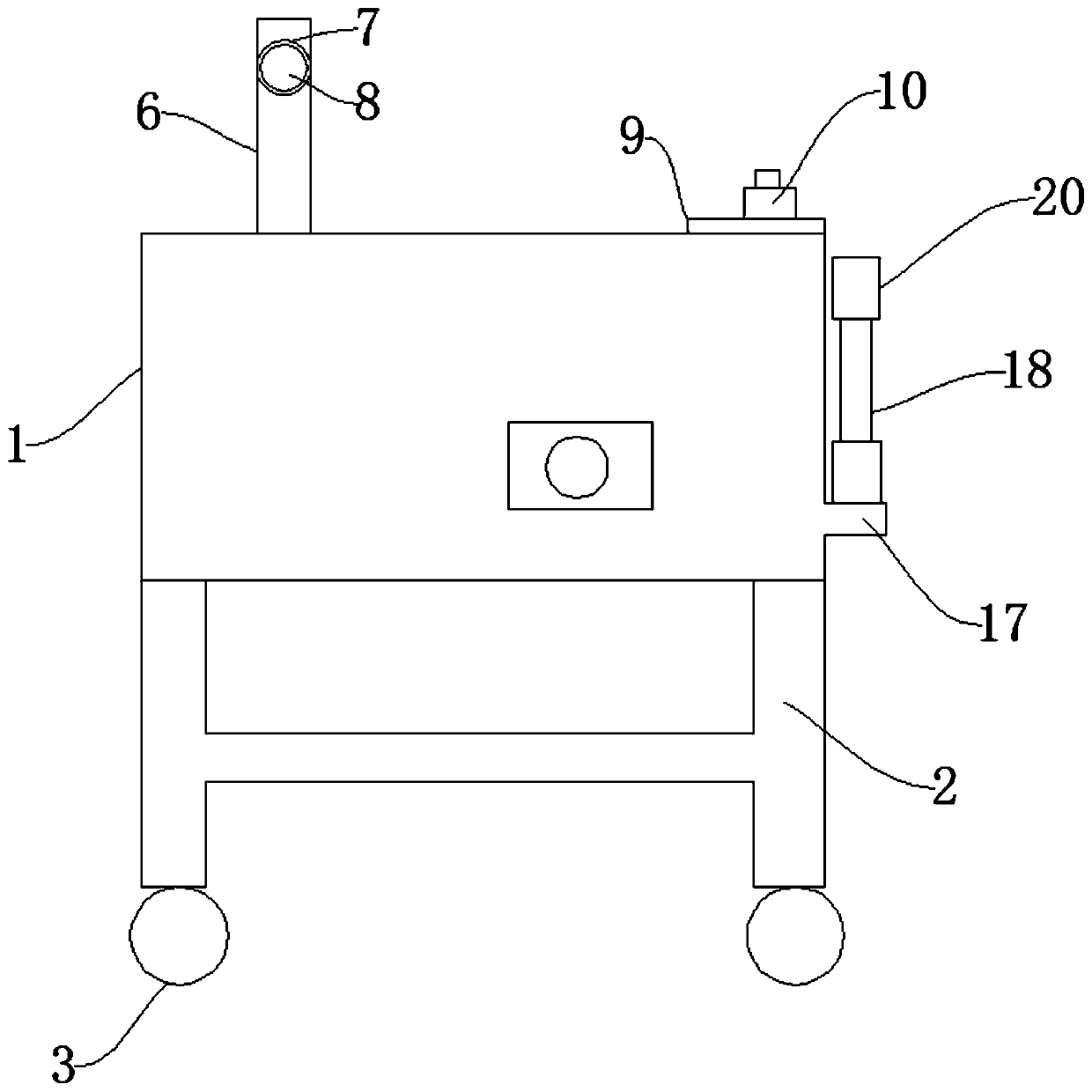

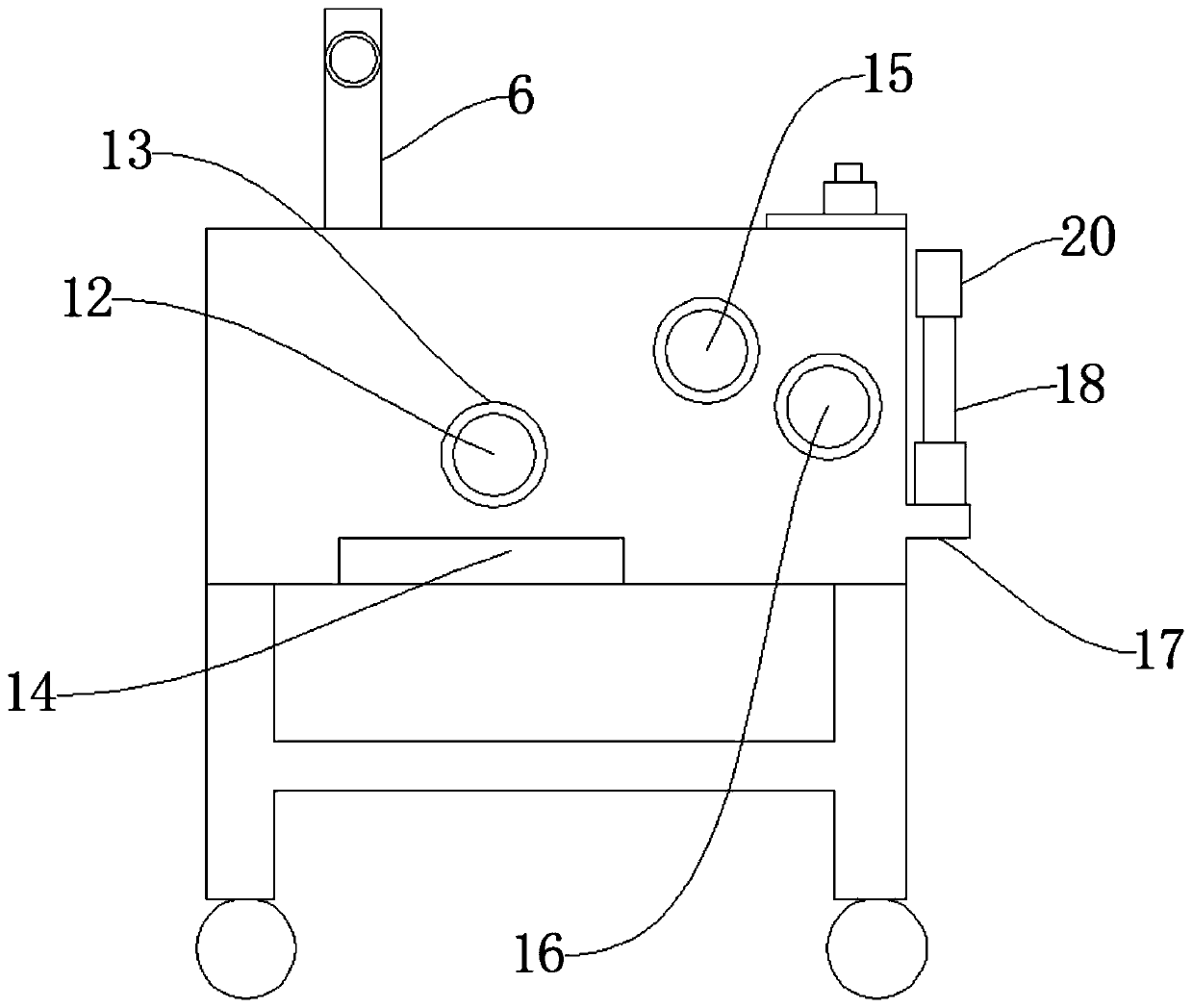

[0031] Such as Figure 1-Figure 5 As shown, the present invention provides a technical solution: a tape unwinding and cutting device, including a working box 1, a bracket 2, a pulley 3, and a control panel 4, a bracket 2 is installed under the working box 1, and a pulley 3 is installed under the bracket 2 , the pulley 3 is used to facilitate the movement of the device, the control panel 4 is installed on the front of the work box 1, the switch button 5 is installed on the control panel 4, the support rod 6 is welded on the top of the work box 1, and a No. 1 rotating column 7 is installed on the support rod 6 , the No. 1 rotating column 7 is provided with a No. 1 rotating rod 8, and the side of the supporting rod 6 is provided with a placing plate 9, which is welded with the working box 1, and an infrared probe 10 is installed on the placing plate 9, and the infrared probe 10 is used for detecting signals , the work box 1 is provided with an outlet 11, the outlet 11 is formed i...

no. 2 example

[0034] The difference between the second embodiment and the first embodiment is:

[0035] The working box 1 is welded to the support 2, and the pulley 3 and the support 2 are connected by bolts, which ensures the firmness of the connection between the working box 1 and the support 2, ensures that the pulley 3 is easy to disassemble, and improves the rationality of the device design.

no. 3 example

[0037] The difference between the third embodiment and the first embodiment is:

[0038] The control panel 4 is connected with the working box 1 by bolts, and the switch button 5 is inlaid on the control panel 4, which ensures that the control panel 4 is convenient for disassembly and maintenance, and ensures the convenience of the switch button 5 to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com