Hydrodynamic cavitation device for pharmaceutical wastewater treatment

A technology for hydrodynamic cavitation, pharmaceutical wastewater, applied in natural water treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of improving the treatment effect, improving the cavitation efficiency, and improving the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

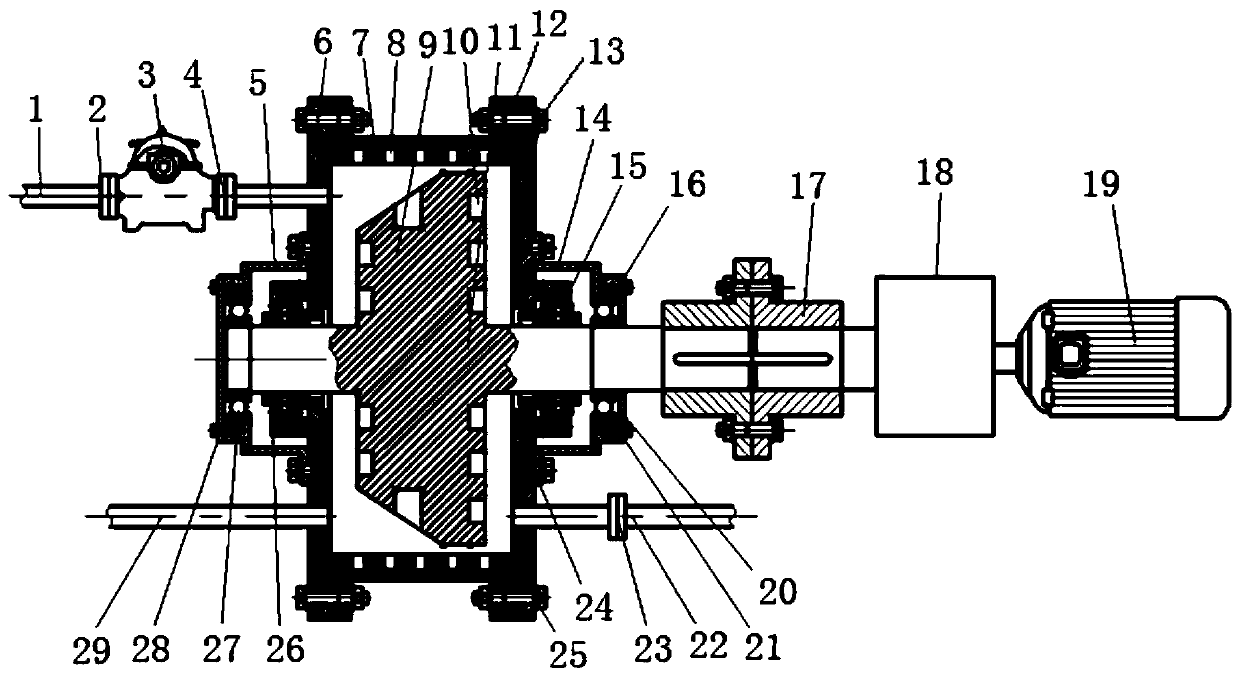

[0023] The hydraulic cavitator for pharmaceutical wastewater treatment of the present invention, such as figure 1 As shown, it includes a stator 7, a rotor 9 and a rotating shaft 11, and the stator 7 can be fixed on the foundation. A cavitation cavity is formed inside the stator 7 . Both ends of the stator 7 are connected with a stator left end cover 6 and a stator right end cover 13 by bolts 25, and a sealing gasket 12 is arranged between the stator 7 and its left and right end covers. The stator 7 and its left end cover 6 and right end cover 13 form a cavitation cavity. Stator blind holes 8 are distributed on the inner wall of the cavitation chamber. The depth of the stator blind holes 8 is 40mm and the diameter is 20mm.

[0024] The stator left end cover 6 and the stator right end cover 13 are respectively connected with the bearing left support cover 5 and the bearing right support cover 14 by screws 24, and the bearing left support cover 5 and the bearing right support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com