Sai Er brick and manufacture process thereof

A manufacturing process, the technology of Searle bricks, applied in the field of refractory materials, can solve the problems of poor heat preservation and heat storage, and increase the energy consumption of kilns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of manufacture craft of Searle brick, comprises following operation steps:

[0039] S1: Ingredients, weighed in sequence by weight percentage

[0040] High alumina bauxite particles 25%

[0041] Andalusite Granules 25%

[0042] Corundum particles 15%

[0043] Kaolin 5%

[0045] Andalusite powder 20%,

[0046] Place in a blender, add water and stir for 10 minutes to obtain a mixture with a water content of 8%, and set aside;

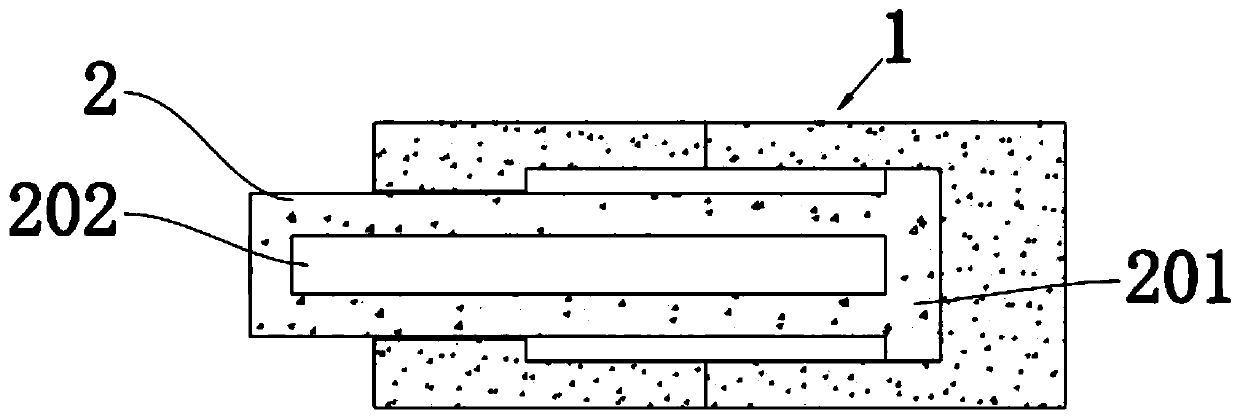

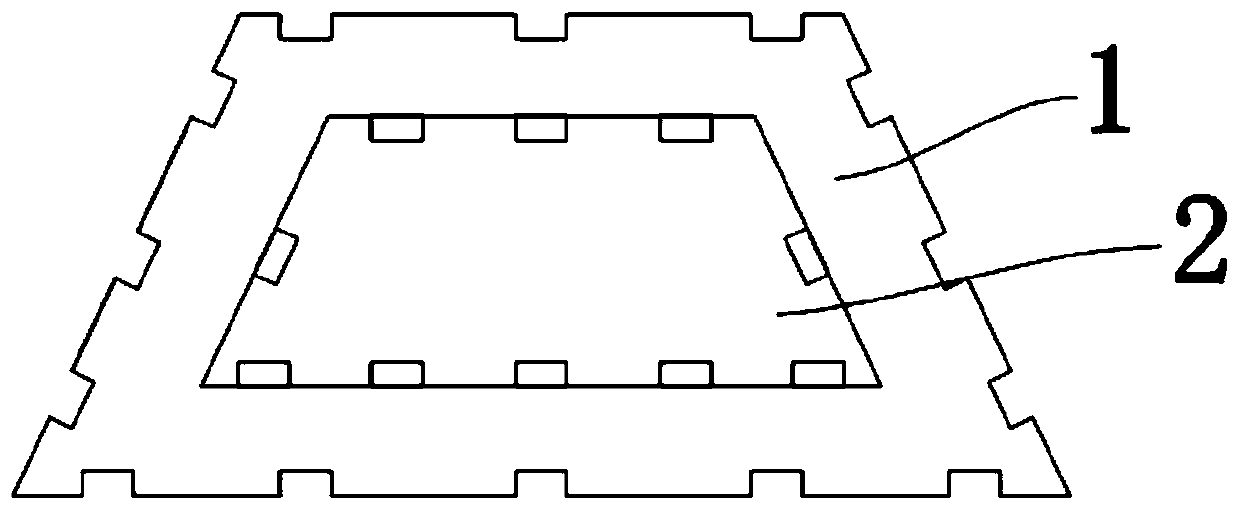

[0047] S2: Prepare the insulation brick core 2, put the mixture into the mold, and make the insulation brick core 2 under the pressure of 500KN, then place the insulation brick core 2 in the rotary kiln for sintering at 1200°C for 4 hours, take out the heat preservation after natural cooling Brick core 2 spare;

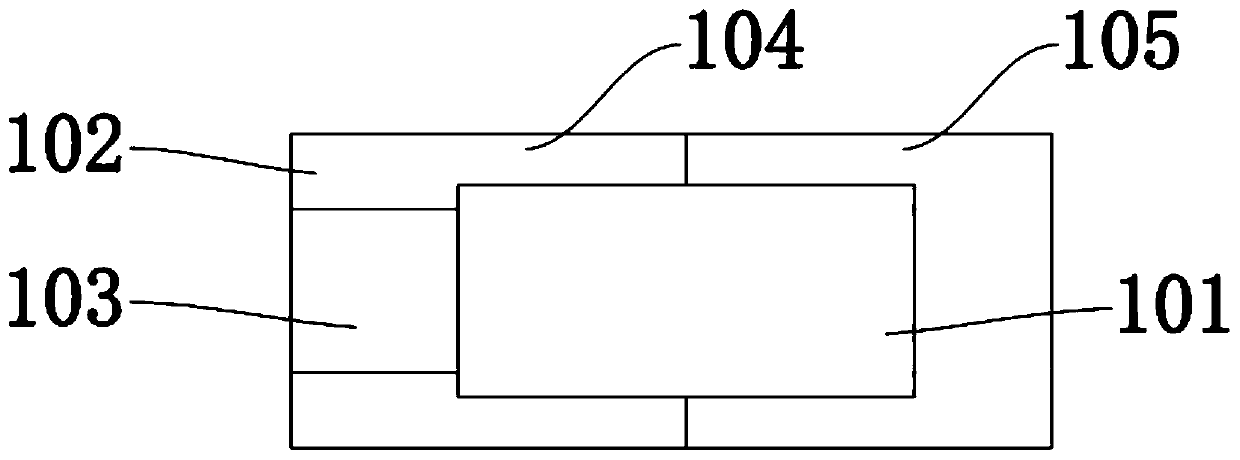

[0048] S3: Prepare the load-bearing brick body 1, then add the mixture into the press mold, press the left brick body 104 and the right brick body 105 respectively under a pressure of 700KN, and w...

Embodiment 2

[0050] A kind of manufacture craft of Searle brick, comprises following operation steps:

[0051] S1: Ingredients, weighed in sequence by weight percentage

[0052] High alumina bauxite particles 30%

[0053] Andalusite Granules 30%

[0054] Corundum particles 10%

[0055] Kaolin 5%

[0056] Corundum powder 10%

[0057] Andalusite Powder 15%,

[0058] Place in a blender, add water and stir for 20 minutes to obtain a mixture with a water content of 9%, and set aside;

[0059] S2: Prepare the insulation brick core 2, put the mixture into the mold, and make the insulation brick core 2 under the pressure of 550KN, then put the insulation brick core 2 in the rotary kiln for sintering at 1250°C for 6 hours, take out the heat preservation after natural cooling Brick core 2 spare;

[0060] S3: Prepare the load-bearing brick body 1, then add the mixture into the press mold, respectively press the left brick body 104 and the right brick body 105 under a pressure of 740KN, and wet...

Embodiment 3

[0062] A kind of manufacture craft of Searle brick, comprises following operation steps:

[0063] S1: Ingredients, weighed in sequence by weight percentage

[0064] High alumina bauxite particles 20%

[0065] Andalusite Granules 30%

[0066] Corundum particles 15%

[0067] Kaolin 10%

[0068] Corundum powder 10%

[0069] Andalusite Powder 15%,

[0070] Place in a blender, add water and stir for 30 minutes to obtain a mixture with a moisture content of 10%, and set aside;

[0071] S2: Prepare the insulation brick core 2, put the mixture into the mold, and make the insulation brick core 2 under the pressure of 600KN, then put the insulation brick core 2 in the rotary kiln for sintering at 1300°C for 8 hours, take out the heat preservation after natural cooling Brick core 2 spare;

[0072] S3: Prepare the load-bearing brick body 1, then add the mixture into the press mold, respectively press the left brick body 104 and the right brick body 105 under a pressure of 780KN, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com