A kind of pla/pbat composite material and preparation method thereof

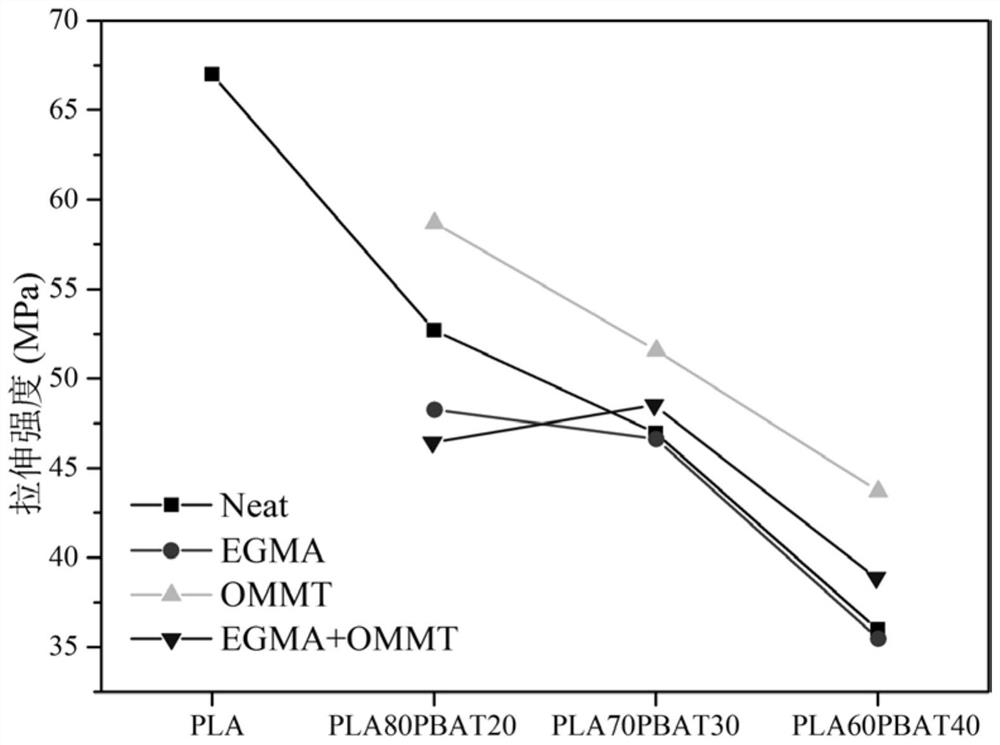

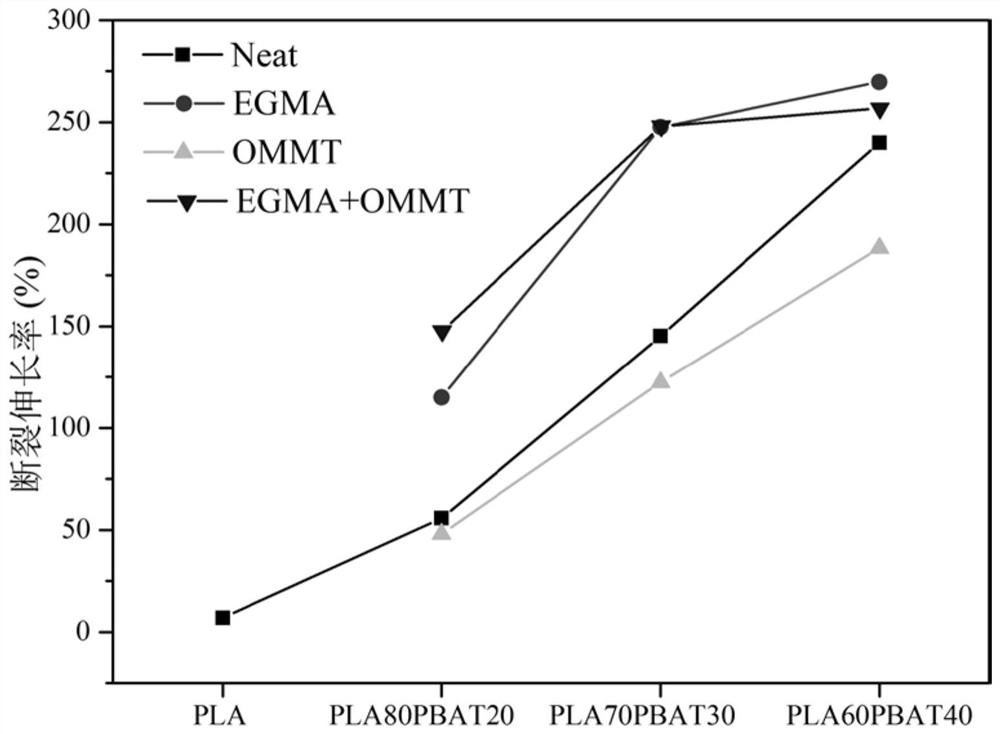

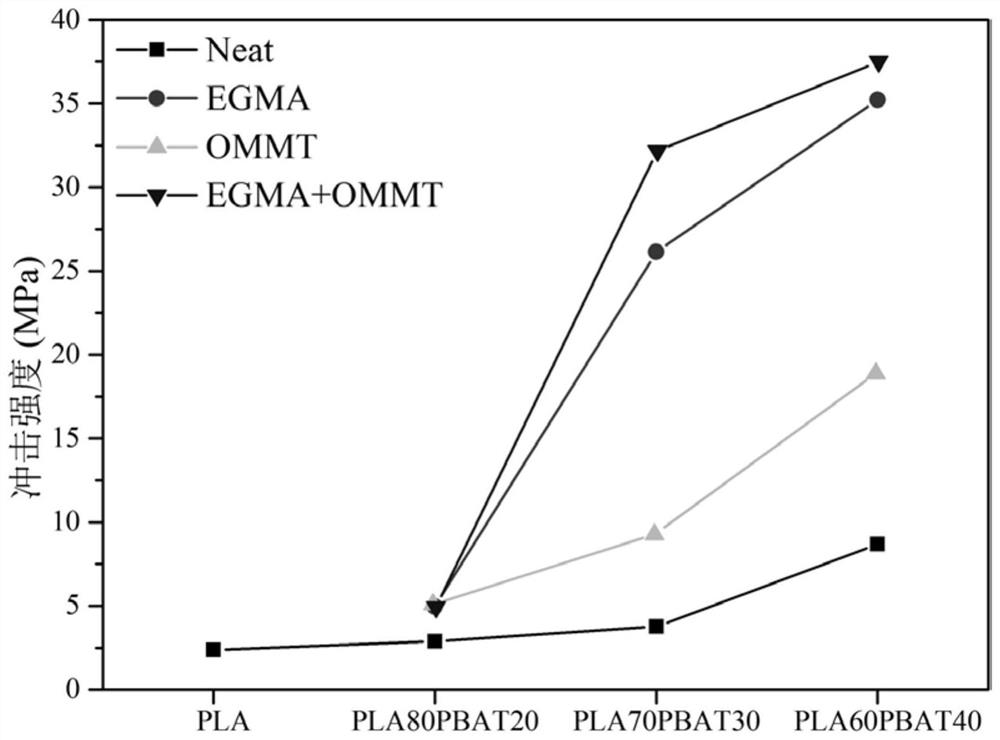

A composite material, PLA60 technology, applied in the field of polymer material preparation, can solve the problems of difficult control of product quality, unfavorable material melting and dispersion, poor heat transfer performance of plastics, etc., to achieve the promotion of stress transfer efficiency, material toughness improvement, strong stress The effect of transferability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] This example provides 3 kinds of PLA / PBAT composite materials and their preparation methods, and provides 10 sets of corresponding comparative examples.

[0034] According to embodiment 1~3 shown in table 1, comparative example 1~4 shown in table 2, the formula of comparative example 5~7 shown in table 3 and comparative example 8~10 shown in table 4 carries out batching, then Mix the above ingredients uniformly for 30 minutes, and then use a balanced three-screw dynamic extruder for melt blending. The temperature of each section of the three-screw mixing part is 120°C-130°C-150°C-185°C-185°C-185°C –185°C–185°C–185°C–130°C–120°C, the temperature of each section and die head of the single-screw extrusion part is 185°C–185°C–185°C–185°C–185°C–185°C–180°C, three The screw speed of the screw mixing part is 80 rpm, the screw speed of the single-screw extrusion part is 60 rpm, extruded, cooled, air-dried, pelletized, and the above PLA / PBAT composite material can be obtained af...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap