All-steel large-template aluminum alloy plug plate structure and manufacturing method thereof

A technology of aluminum alloy formwork and large formwork, which is applied in the fields of formwork/formwork/work frame, construction components on-site preparation, building construction, etc., which can solve the problems of speeding up the construction progress of concrete structures, reducing engineering construction costs, and slow construction progress and other issues, to achieve high commercial application and promotion value, easy assembly and disassembly of templates, and the effect of improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

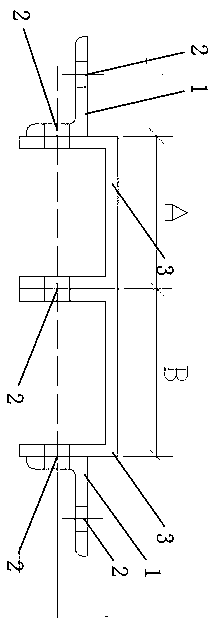

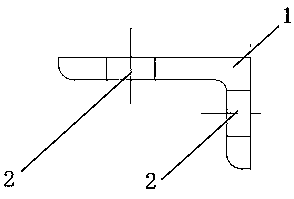

[0024] Embodiment: This embodiment is a combination of an A-width shaped aluminum alloy formwork and a B-width shaped aluminum alloy formwork. The width of the A wide shaped aluminum alloy template is (100mm), the width of the B wide shaped aluminum alloy template is (110mm), the A wide shaped aluminum alloy template and the B wide shaped aluminum alloy template are both U-shaped templates, that is, the middle horizontal plate It forms a U-shaped formwork with two side panels. The included angle between the middle horizontal plate and the two side plates is 90 degrees.

[0025] One side plate of the A wide shaped aluminum alloy formwork is connected with a side plate of the B wide shaped aluminum alloy formwork through pins and fixed with a wedge plug;

[0026] The other side plate of the A wide shaped aluminum alloy formwork is connected with the narrow angle side of the first angle aluminum through a pin and fixed with a wedge; the wide angle side of the first angle aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com