A high-voltage cable seal lead water corrosion detection method and device

A high-voltage cable, corrosion detection technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as damage to the insulation structure of power cables, and achieve reasonable design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-voltage cable seal lead water ingress corrosion detection method, comprising the following steps:

[0037] Step 1. Wrap tinfoil in a spiral and overlapping manner at the lead seal of the high-voltage cable.

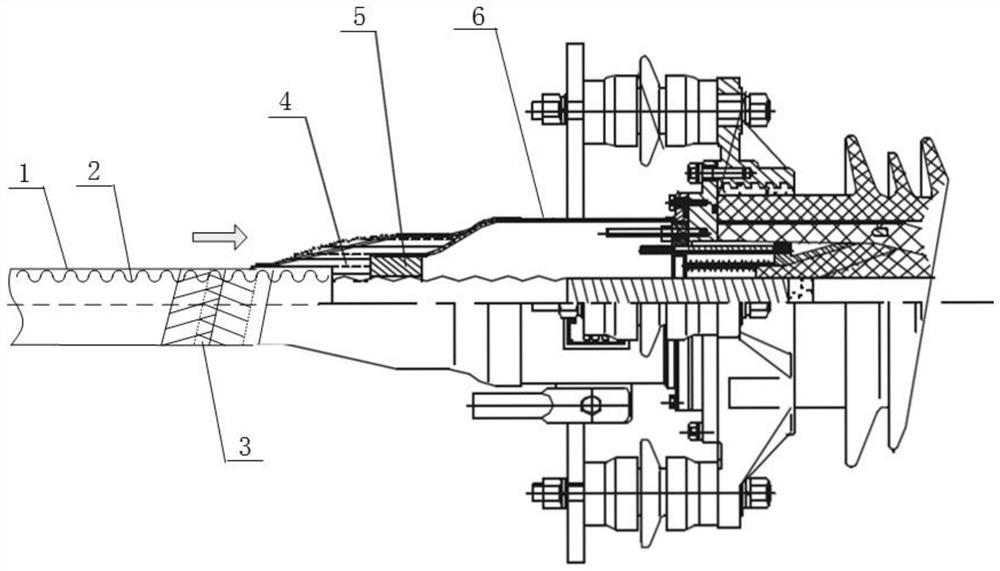

[0038] Such as figure 1 As shown, the corrugated protective sheath 2 and the outer sheath 1 are provided on the body of the existing high-voltage cable, and the lead seal 4 and the inner lining layer 5 are provided on the joint and the outer sheath 6 is provided.

[0039] In this embodiment, the tinfoil 3 is wrapped around the cable body at a distance of 30 cm from the lead sealing position of the high-voltage cable. The tinfoil is in a strip shape with a width of 20 cm. The wrapping degree of tinfoil is 1cm, and the tinfoil is wrapped all the way to the inner lining. After winding, there is a margin of 30cm above and below the lead seal of the high-voltage cable.

[0040] Step 2. Wrap the inflatable bag on the outer layer of tin foil, and use the air pum...

Embodiment 2

[0053] Based on the same inventive concept, the present invention also provides a high-voltage cable seal lead water ingress corrosion detection device, the problem-solving principle of which is similar to the above-mentioned high-voltage cable lead seal water ingress corrosion detection method, and the repetition will not be repeated.

[0054] The high-voltage cable seal lead water ingress corrosion detection device includes:

[0055] The winding module is used to wind the first tinfoil at the lead seal of the high-voltage cable;

[0056] The blowing module is used to wrap the inflatable bag on the outer layer of the first tinfoil and blow air into the inflatable bag until the inflatable bag is fully inflated, then stop injecting gas;

[0057] The deflation module is used to release the gas in the inflatable bag, and take out the first tinfoil for standby;

[0058] The winding module is also used to wind the second tinfoil at the lead seal of the high-voltage cable;

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com