Microseismic/acoustic emission source localization method in complex structure with empty space

An acoustic emission source and complex structure technology, applied in positioning, measuring devices, instruments, etc., can solve the problems of poor positioning accuracy and achieve the effect of improved positioning accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

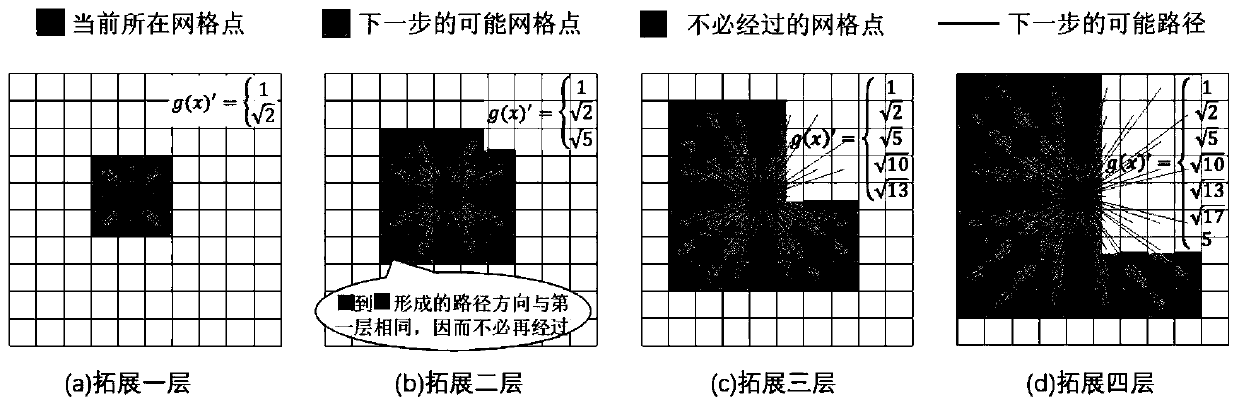

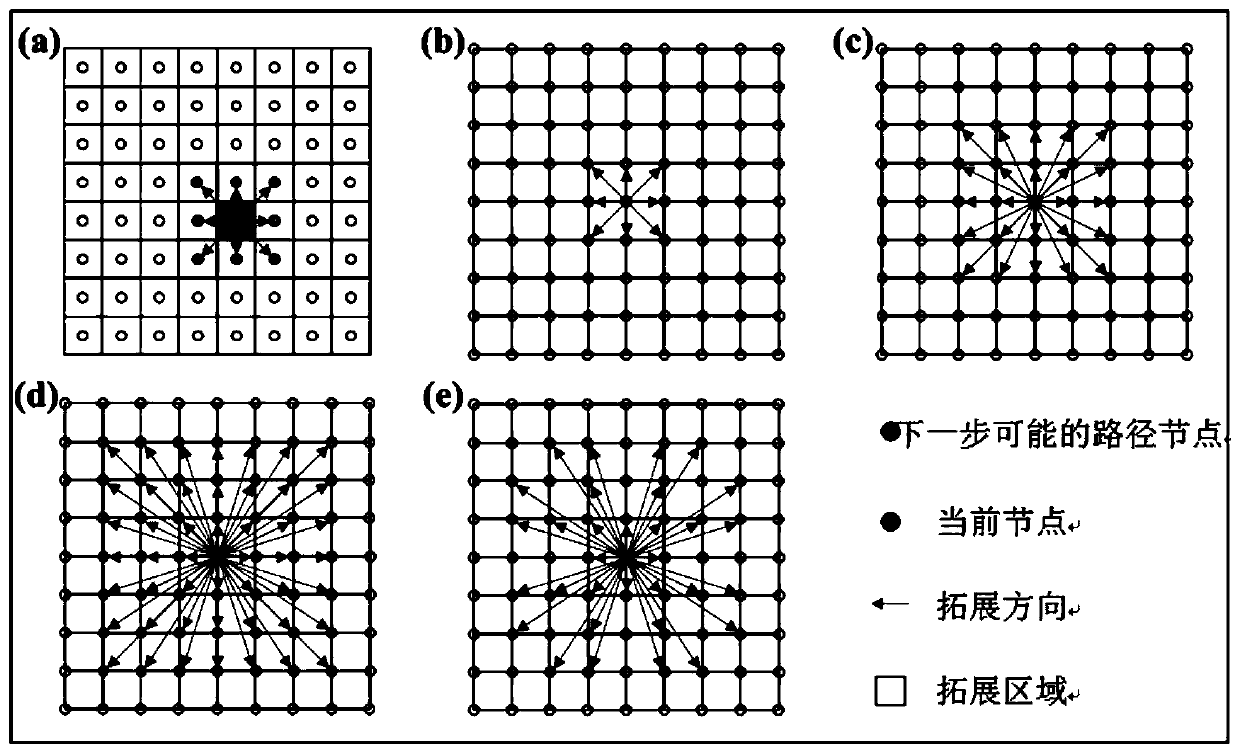

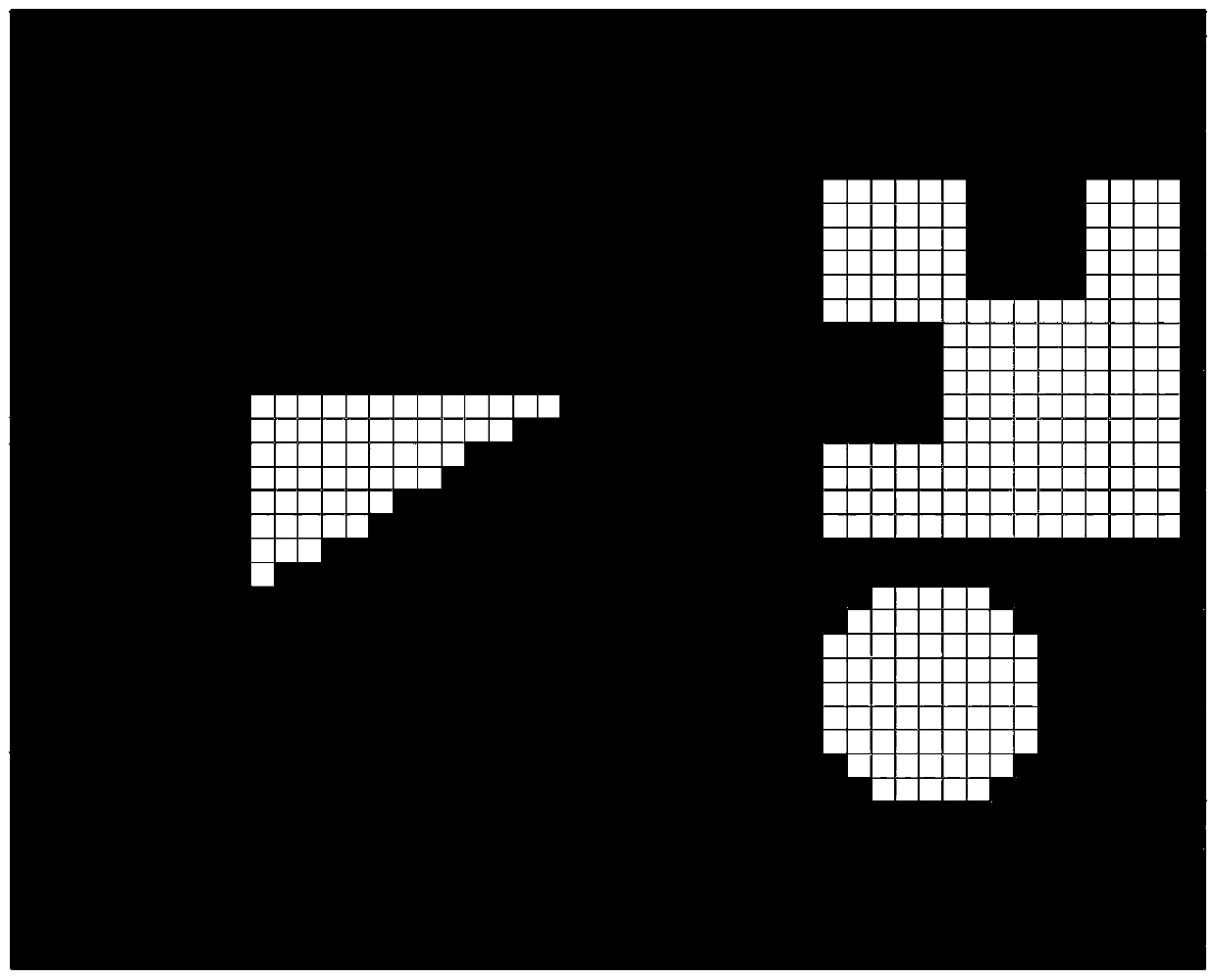

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be further described in detail with reference to the drawings and specific embodiments.

[0035] The invention discloses a method for locating a microseismic / acoustic emission source in a complex structure containing a void area, which includes the following steps:

[0036] Step 1: Environmental preparation;

[0037] Install one sensor at multiple different positions on the two-dimensional positioning area (install one sensor at each of the four different positions on the two-dimensional positioning area);

[0038] Step 2: Data collection;

[0039] Receive the P wave signal generated by the unknown real microseismic / acoustic emission source through the sensor, and record the kth sensor S k The actual time of receiving the P wave signal is Calculate two sensors S l And sensor S k The difference between the actual time when the P wave signal is received m is the total number of sensors that receive P wave signals;

[0040] Step 3: Calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com