Five-degree-of-freedom piezoelectric motion platform and its excitation method

A motion platform, degree of freedom technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of complex structure, limited travel, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

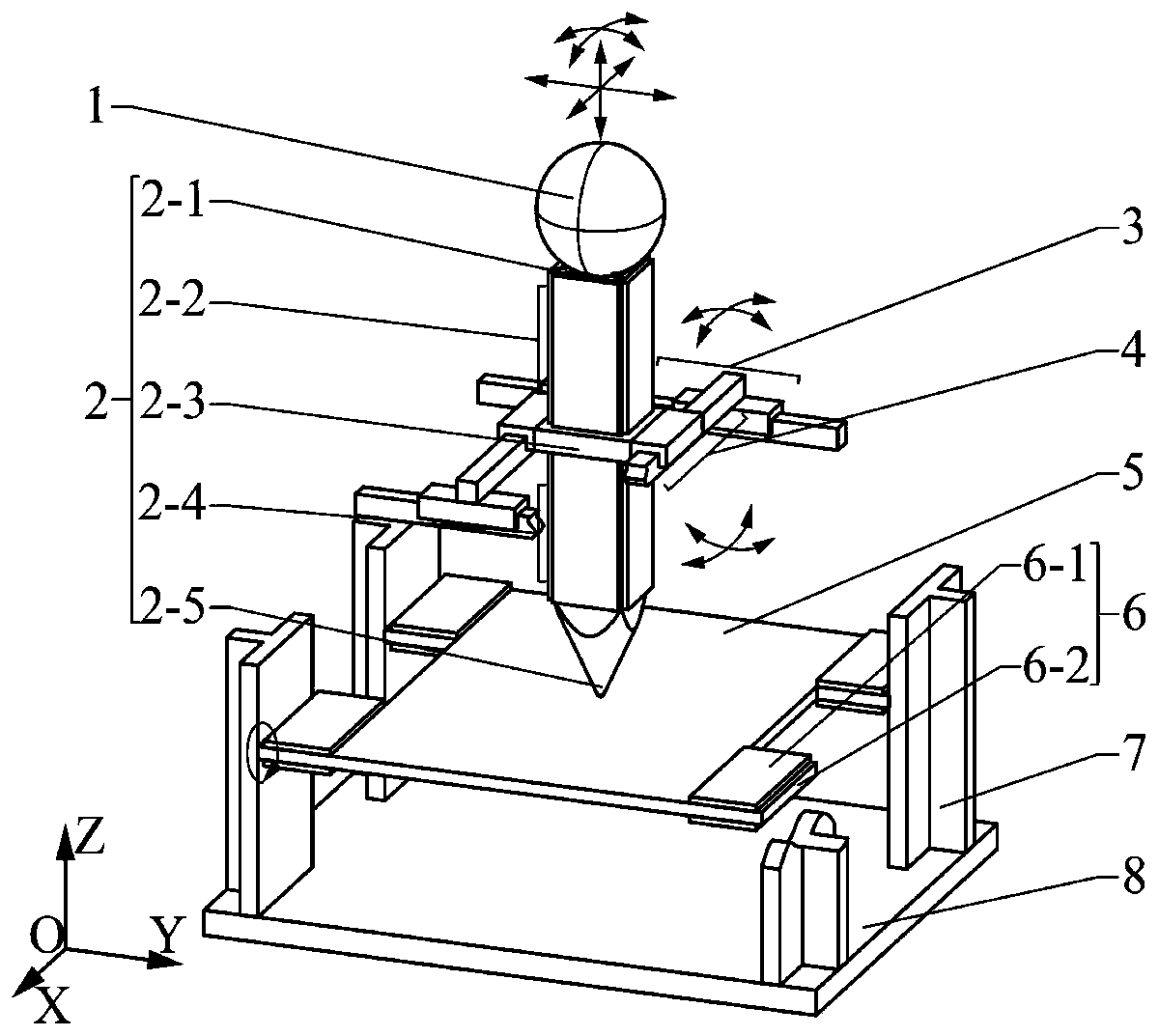

[0078] The following is attached with the manual figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 This embodiment will be further described in detail. This embodiment provides a figure 1 The ultra-precise five-degree-of-freedom piezoelectric motion platform shown. The motion platform includes a mover 1, a multi-output drive unit 2, a transverse guide rail 3, a longitudinal guide rail 4, a support plate 5, a single output drive unit 6, a lateral pressure plate 7 and a base 8; the multi-output drive unit 2 includes The upper side driving foot 2-1, the upper side two-way bending unit 2-2, the fixing clip 2-3, the lower side two-way bending unit 2-4 and the lower side driving foot 2-5; the single output driving unit 6 includes a press The electric ceramic sheet 6-1 and the middle driving foot 6-2; the upper driving foot 2-1, the upper bidirectional bending unit 2-2, the fixing clip 2-3, the lower bidirectional bending unit 2-4 and the lower The side drive legs 2-5 ar...

specific Embodiment 2

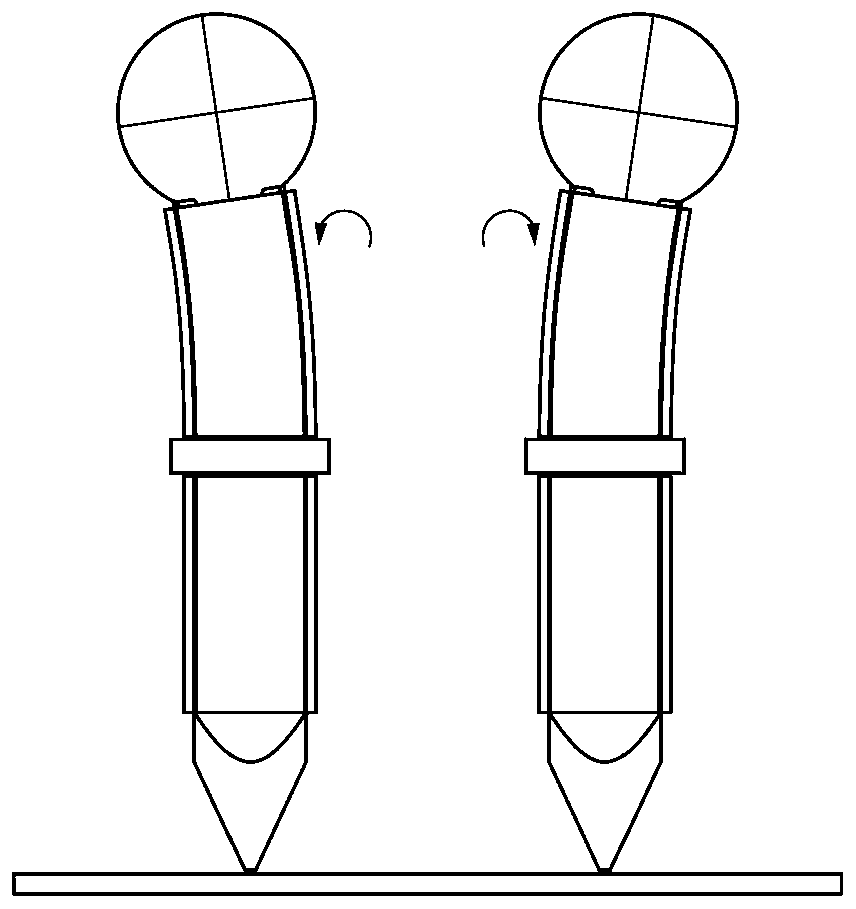

[0083] The following is attached with the manual figure 1 , Figure 6 , Figure 7 , Figure 8 This embodiment will be described in further detail. This embodiment provides a figure 1 The excitation method of the ultra-precision five-degree-of-freedom piezoelectric motion platform is shown. This excitation method can realize the ultra-precision four-degree-of-freedom movement of the mover 1 with a large output stroke, including linear motion along the Y-axis direction and the X-axis direction and orbiting The rotational movement in the Y-axis direction and the X-axis direction can realize nanoscale resolution by adjusting the amplitude and application time of the excitation voltage signal.

[0084] The excitation method for realizing the two-way linear motion of the mover 1 along the Y-axis direction includes the following steps:

[0085] The first step: press the mover 1 on the upper driving foot 2-1, and adjust the pressing force between the two, press the lower driving ...

specific Embodiment 3

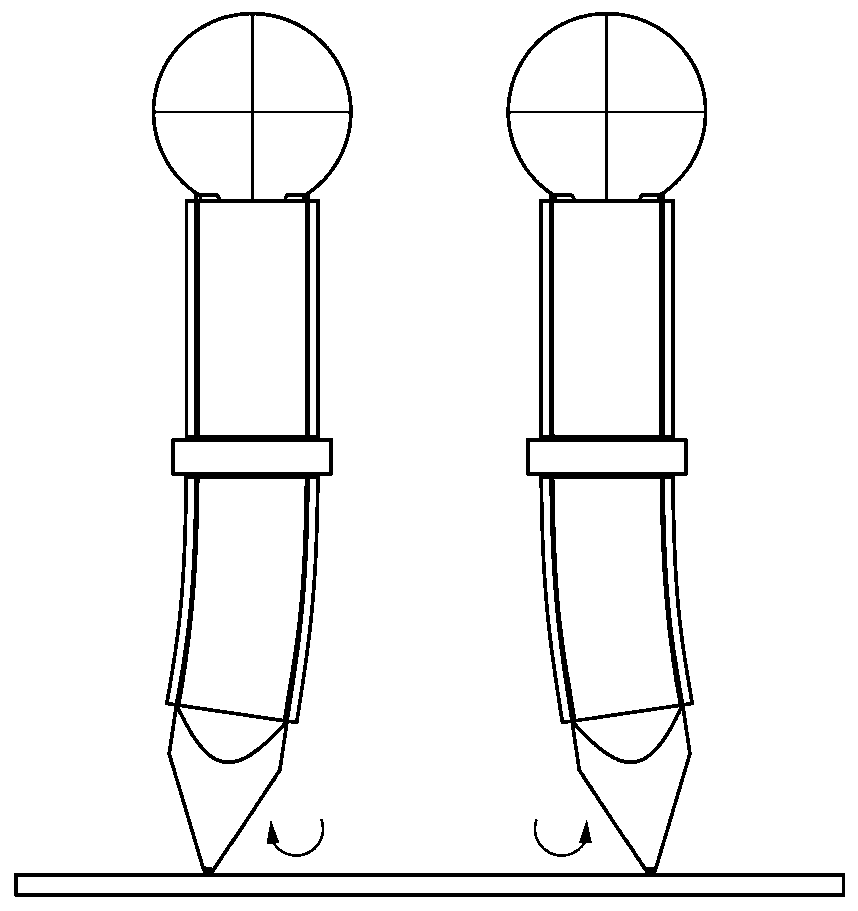

[0123] The following is attached with the manual figure 1 , Figure 9 , Figure 10 , Figure 11 This embodiment will be described in further detail. This embodiment provides a figure 1 The excitation method of the ultra-precision five-degree-of-freedom piezoelectric motion platform is shown. This excitation method can realize the ultra-precision single-degree-of-freedom lifting motion of the mover 1 with a large output stroke, that is, the linear motion along the Z-axis direction. By adjusting the excitation voltage signal The amplitude and application time can achieve nanoscale resolution.

[0124] The excitation method for realizing the two-way linear motion of the mover 1 along the Z-axis direction includes the following steps:

[0125] The first step: press the mover 1 on the upper driving foot 2-1, and adjust the pressing force between the two, press the lower driving foot 2-5 on the support plate 5, and adjust the two Press the middle driving foot 6-2 against the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com