Double-row-staggered spoon and belt type precise potato seeding device

A potato and seed metering technology, which is applied to potato planters, planting methods, applications, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effects of low labor intensity, high production efficiency, and long equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

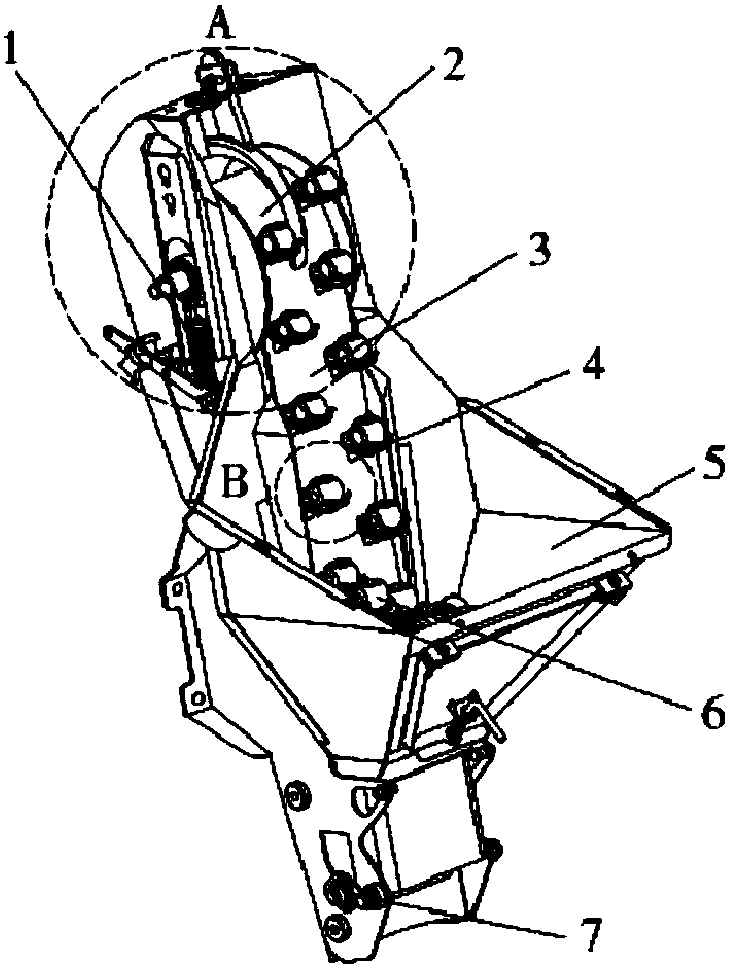

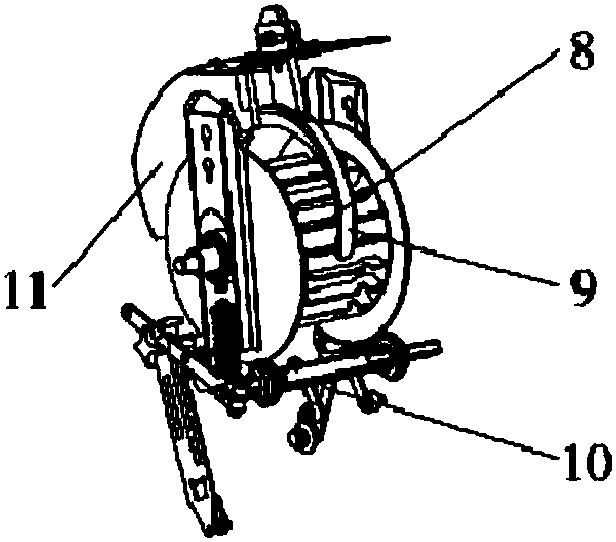

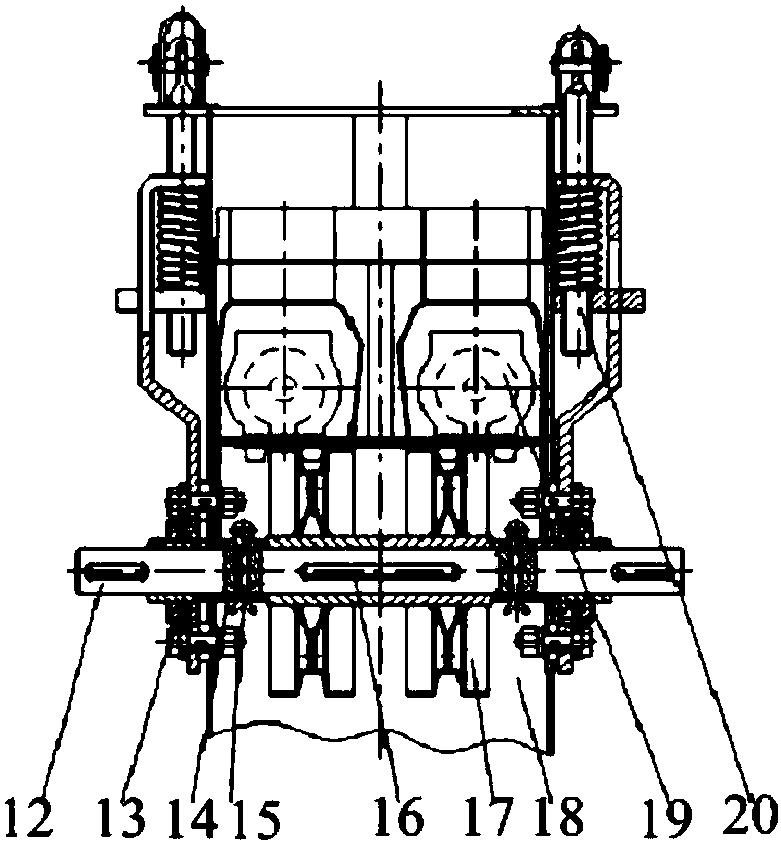

[0020] exist figure 1 and figure 2 Among them, including tensioning device, active drive assembly, flexible seed belt, seed taking concave spoon, anti-overhead seed filling box, potato seed, driven pulley, anti-entrainment diversion ejector, driving pulley, vibration cleaning Seed device, seed protection cover, in which the working process of the seed metering device is mainly divided into five series stages of filling, moving, clearing, guiding and throwing seeds; during normal operation, the potato seeds are filled to the seed under the action of gravity. In the seed box filling area, the flow state of the seed potatoes is controlled through the anti-overhead limit structure of the material of the seed filling box to avoid the phenomenon of seed potato arching, and the number of seed potatoes is controlled through the rubber flip cover on the top of the seed filling box (5) to ensure seed filling The seed potatoes in the area are dynamically balanced; the power is transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com