Anti-bending synchronous and symmetrical automatic grinder device and use method thereof

An automatic grinding machine and anti-bending technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine tool parts, etc., can solve the problems of reduced processing accuracy and inability to meet processing accuracy, and achieve the goal of ensuring processing accuracy requirements, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

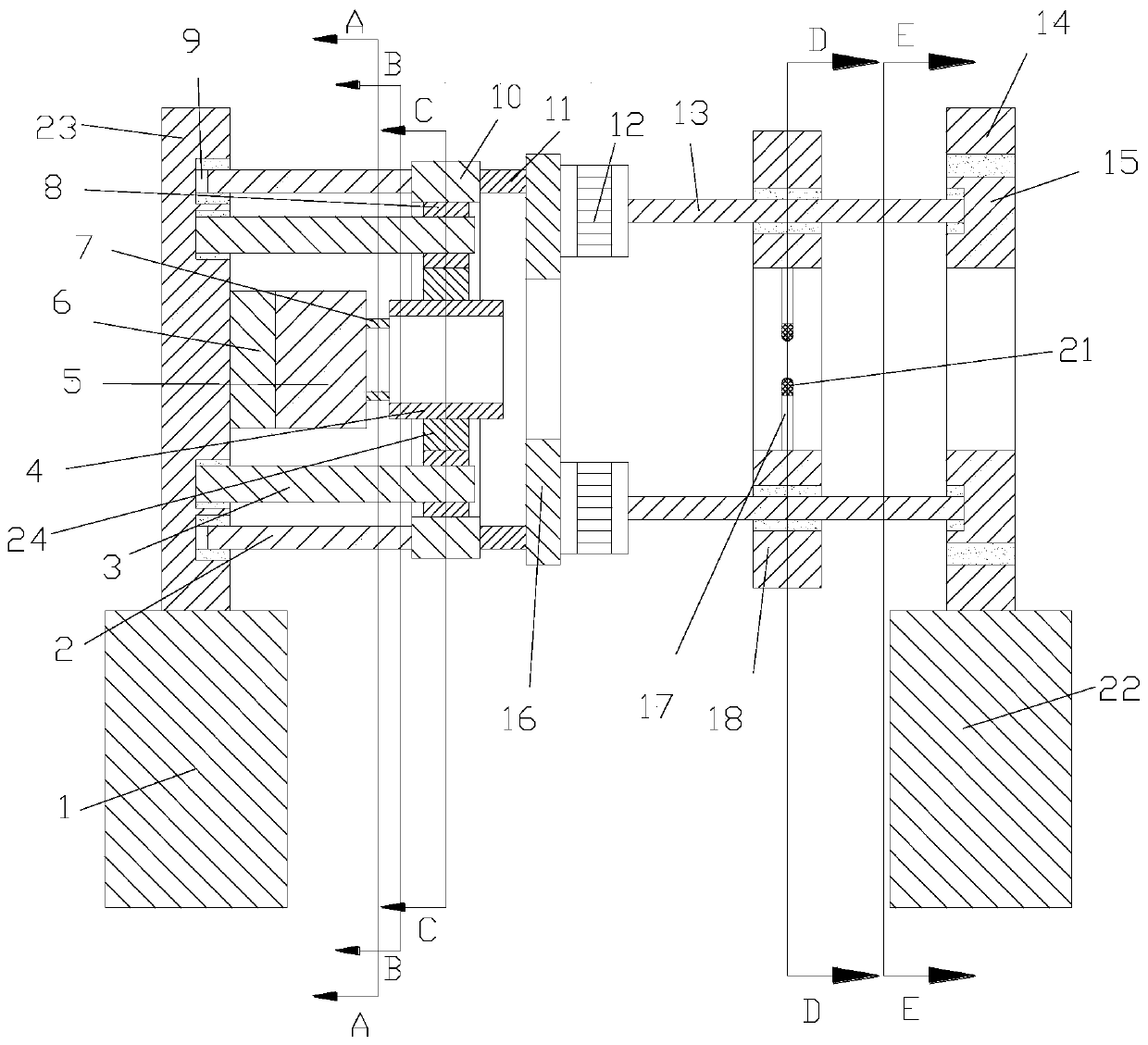

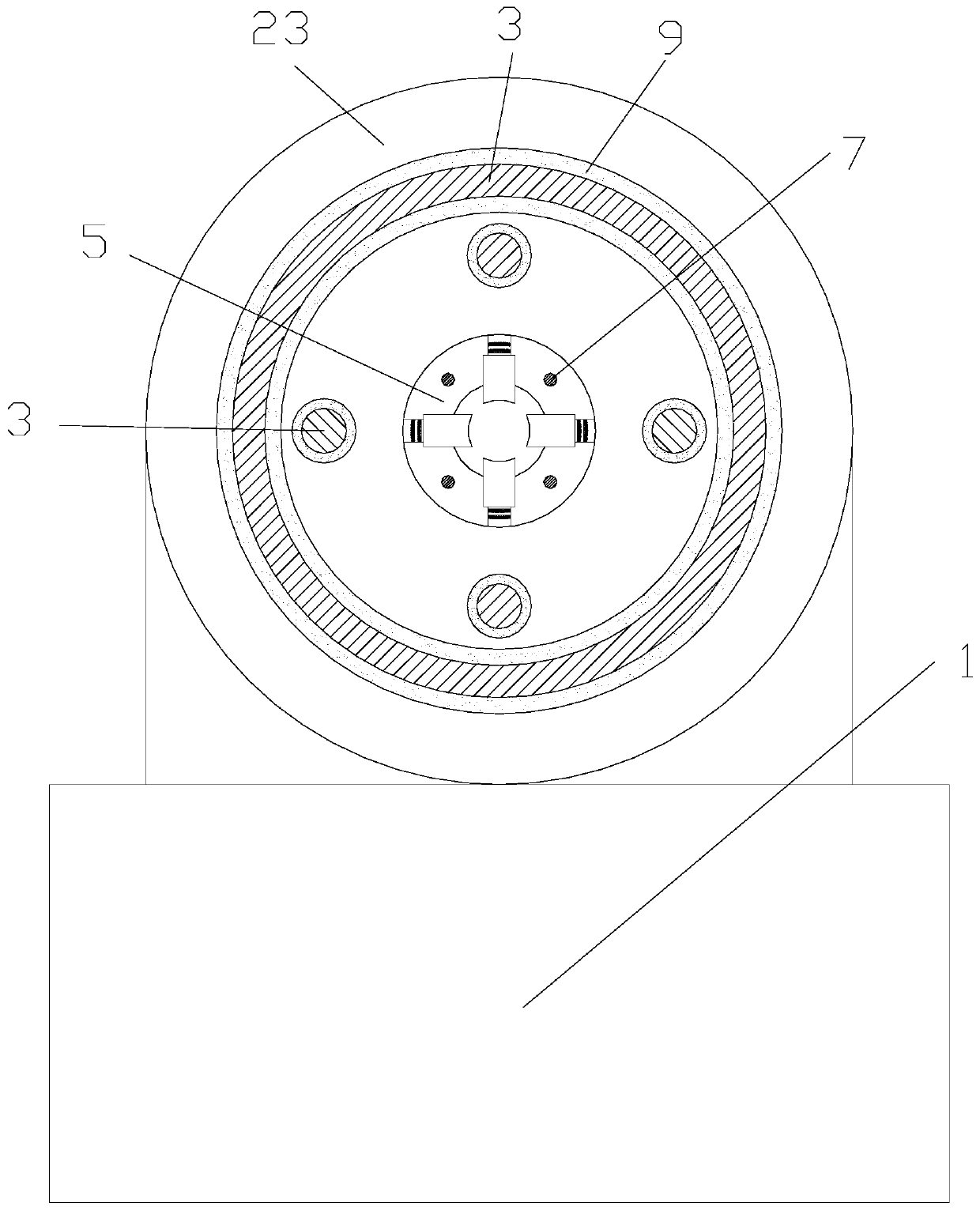

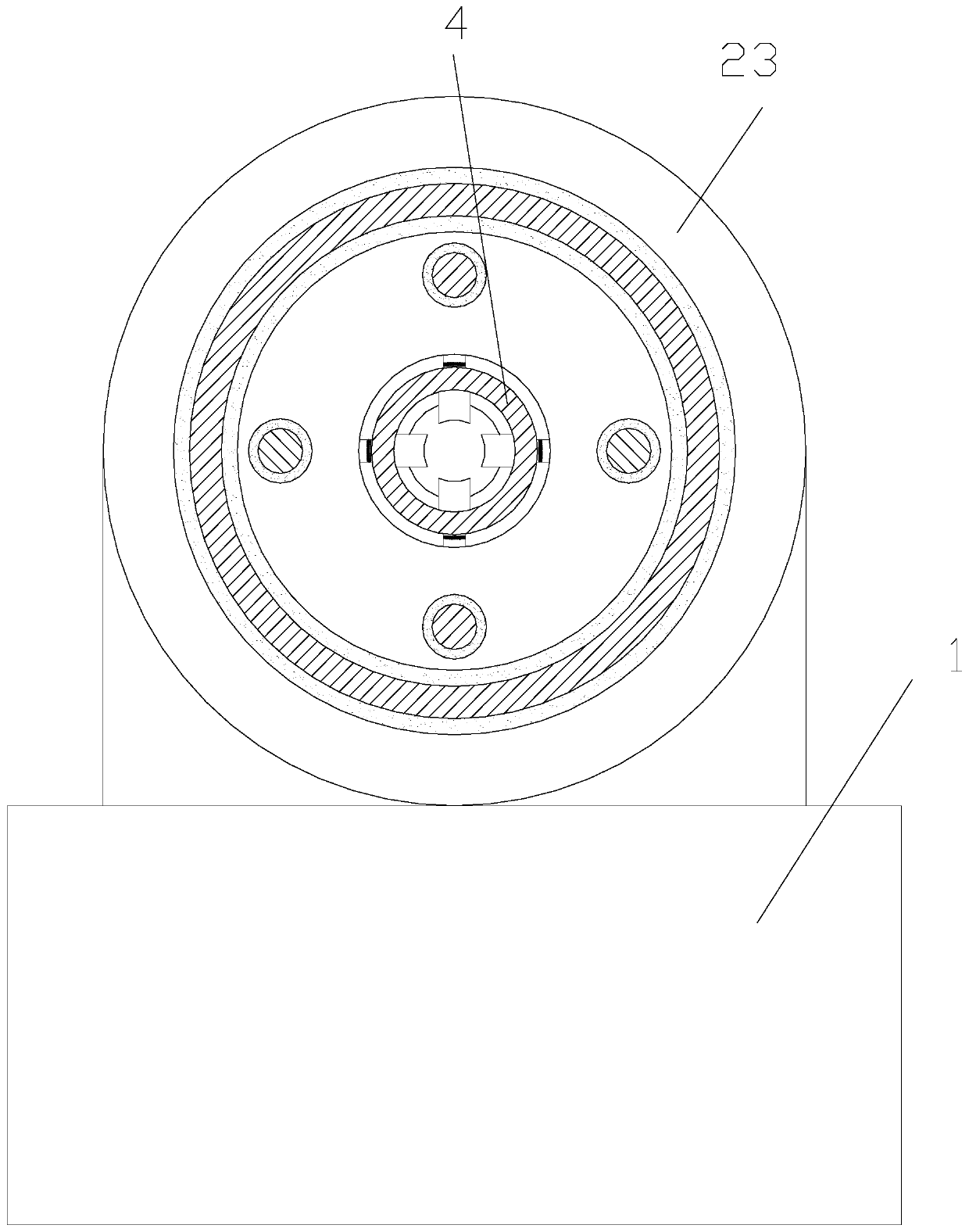

[0017] Refer to attached figure 1 , 2 , 3, 4, 5: This anti-bending synchronous symmetrical automatic grinder device in this embodiment includes a base-1, and a disc plate-23 is fixedly installed on the top of the base-1, and the middle part of the right end of the disc plate-23 A chuck motor 6 is installed, and the right end of the chuck motor 6 is equipped with a four-jaw chuck 5, and the right end of the disc plate-23 is provided with an annular groove 9 whose right end communicates with the outside world, and the inner diameter of the annular groove 9 is much larger than the four jaws. The diameter of the chuck 5, the inside of the annular groove 9 is movably connected with a cylinder one 2 whose right end extends to the front of the four-jaw chuck 5, and the right end of the cylinder one 2 is fixedly equipped with an internal gear ring 10, and the four-jaw chuck 5. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com