Impeller pulling device making impeller to be overhauled and maintained simply and conveniently

A puller and impeller technology, which is applied in the field of impeller repair and maintenance, can solve problems such as inconvenient operation and deformation of the impeller, and achieve the effects of ensuring the integrity rate, reducing production costs, and shortening the time for repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

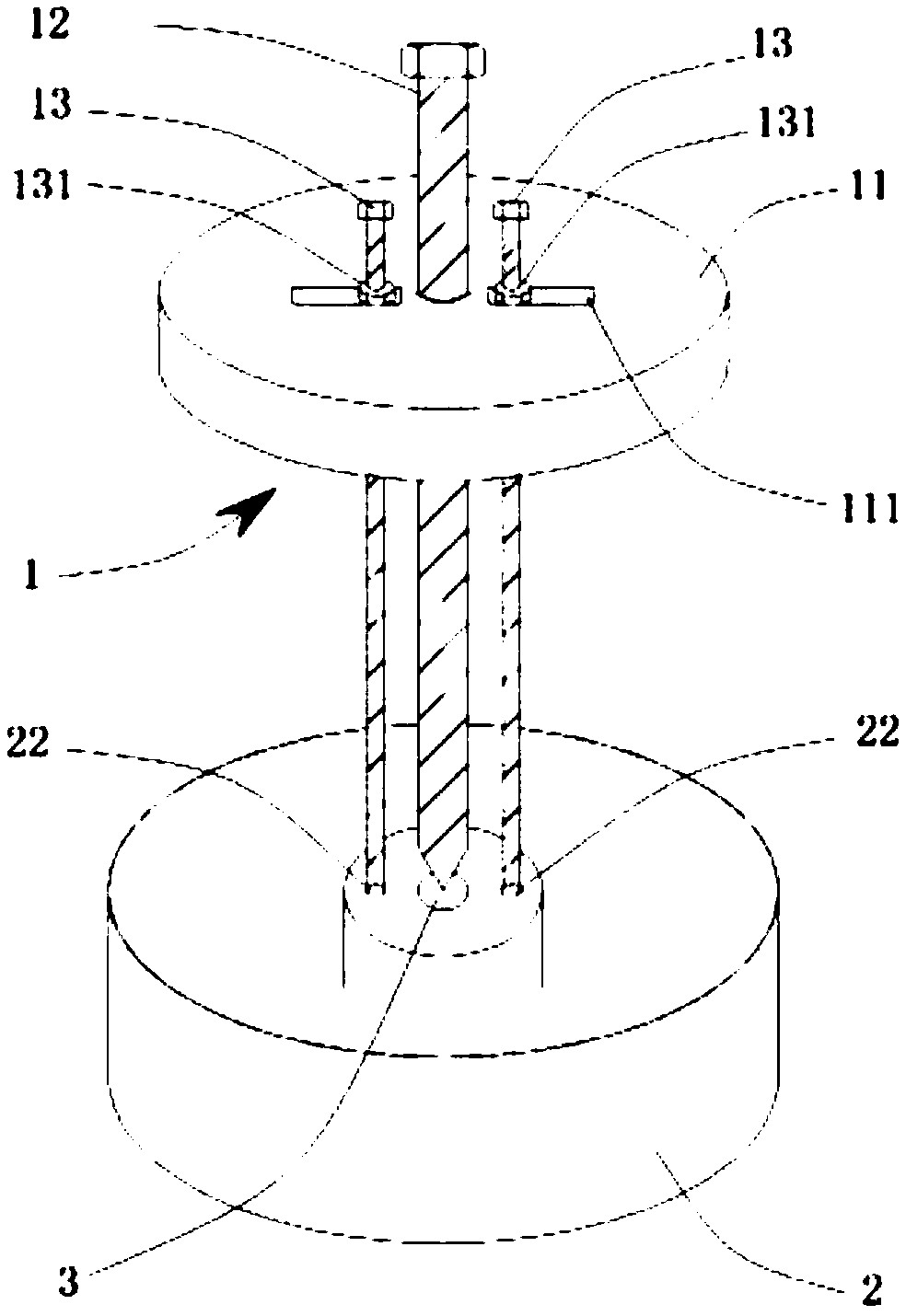

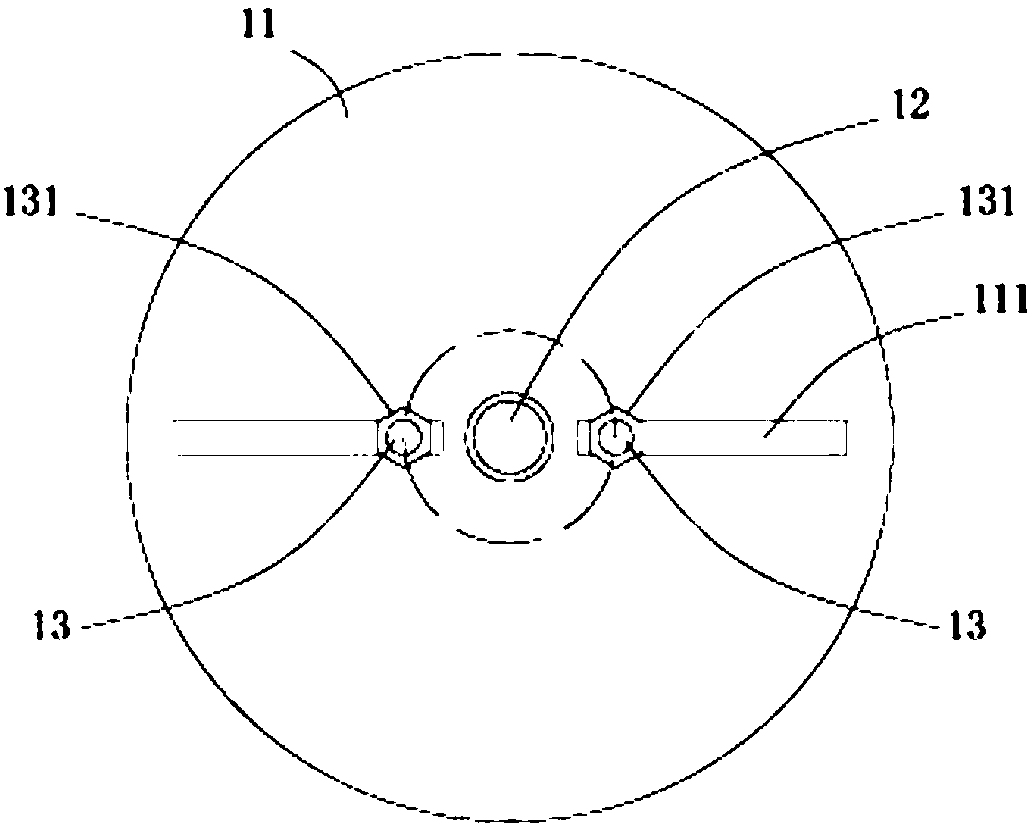

[0021] The present invention proposes a puller 1 which is convenient for maintenance and repair of the impeller, which is mainly used for disassembling the impeller 2 . For example, the impeller 2 of the disassembled centrifugal fan is pulled out from its shaft 3 . Wherein the central position of the impeller 2 is provided with a shaft hole, and the impeller 2 is provided with a plurality of loading and unloading holes 22 around the shaft hole, and the rotating shaft 3 that drives the impeller 2 to rotate is accommodated in the shaft hole. Such as figure 1 and figure 2 Shown, an embodiment of the puller 1 of the present invention. In Embodiment 1, the puller 1 includes a force receiving plate 11 , a lead screw 12 and a plurality of fixing bolts 13 .

[0022] Such as figure 1 and figure 2 As shown, in Embodiment 1, one end of the lead screw 12 passes through the force plate 11 to extend into the shaft hole of the impeller 2 and abut against the rotating shaft 3, and the ...

Embodiment approach 2

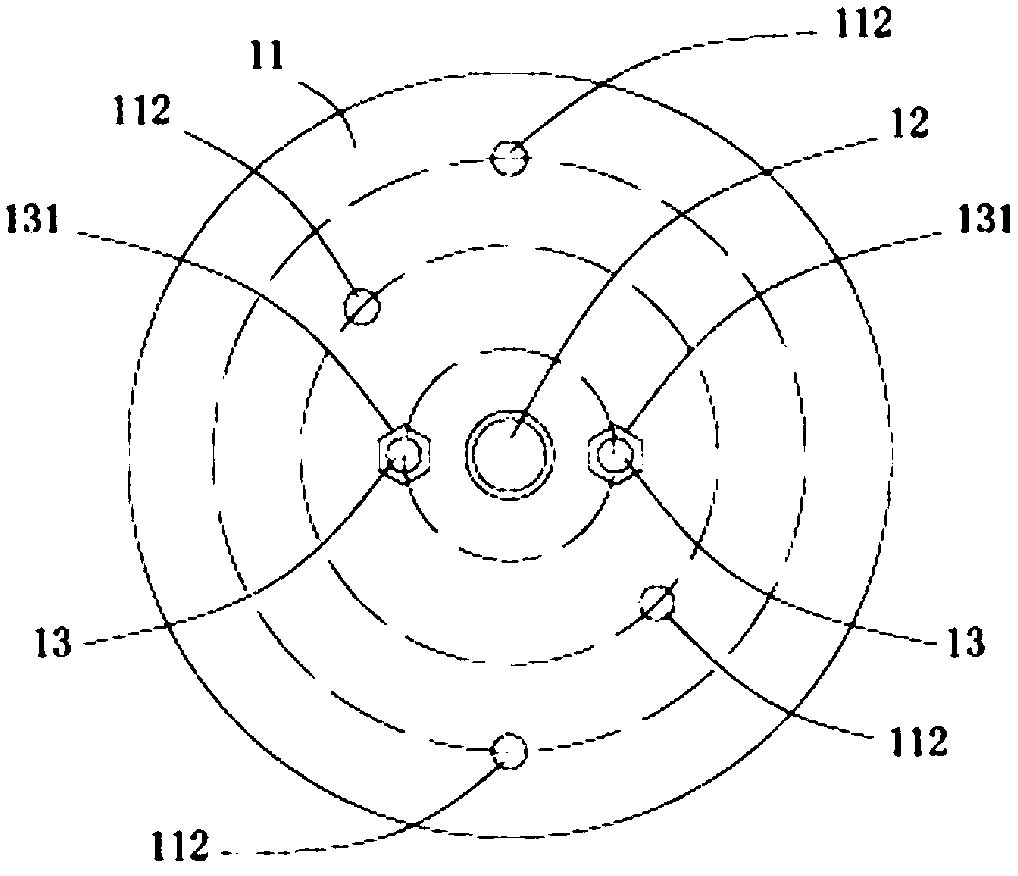

[0029] Another embodiment of the puller 1 of the present invention is substantially the same as Embodiment 1, the difference is: as image 3 As shown, in Embodiment 2, the adjustment groove 111 is replaced by a hole opened on the force receiving plate 11 . Specifically, a central hole with a screw thread is opened at the central position of the force plate 11 for passing the lead screw 12 and screwing it. In addition, a plurality of through holes 112 are opened in the circumferential position of the force receiving plate 11 for respectively passing through a plurality of fixing bolts 13 . It should be noted that, if image 3 As shown, the opening manner of the plurality of through holes 112 should correspond to the specific distribution positions of the loading and unloading holes 22 of the impeller 2 . Moreover, in order to make the puller 1 applicable to impellers 2 of various specifications, the distances between the through holes 112 opened on the force plate 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com