Automobile trunk lid packaging box production technique

A luggage cover and production process technology, applied in packaging, transportation and packaging, machining/deformation, etc., can solve the problems of high labor intensity and low production efficiency of workers, and achieve reduced labor intensity, high production efficiency, and convenient folding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0036] like figure 1 Shown, a kind of automobile trunk lid packaging case production process, carries out according to the following steps:

[0037] S1: Making corrugated packaging board A

[0038] S11: Use an ink printing slotting machine to print a graphic logo on the corrugated cardboard, and press out the transverse crease A1 extending along the width direction and the longitudinal crease A3 extending along the length direction.

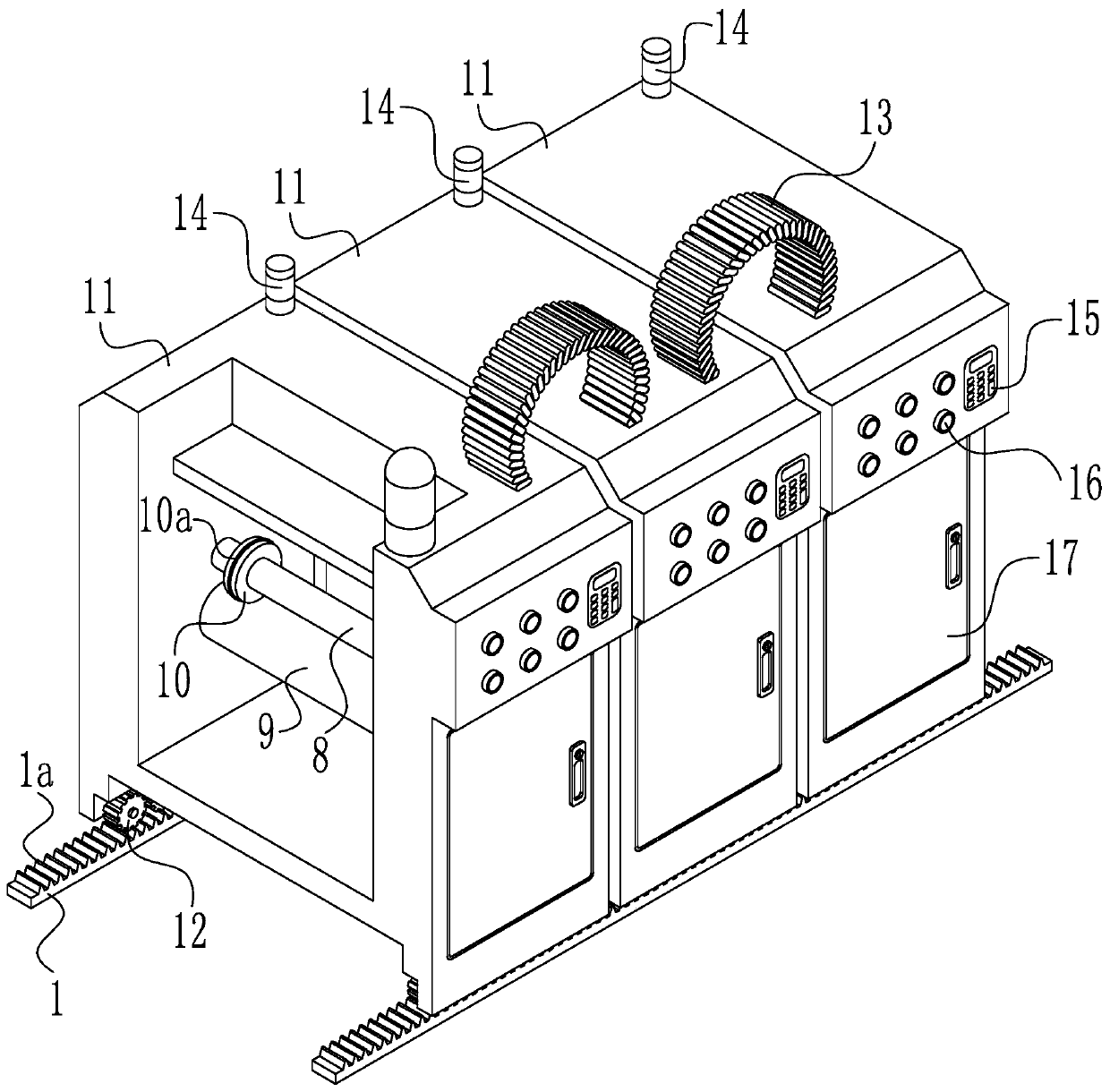

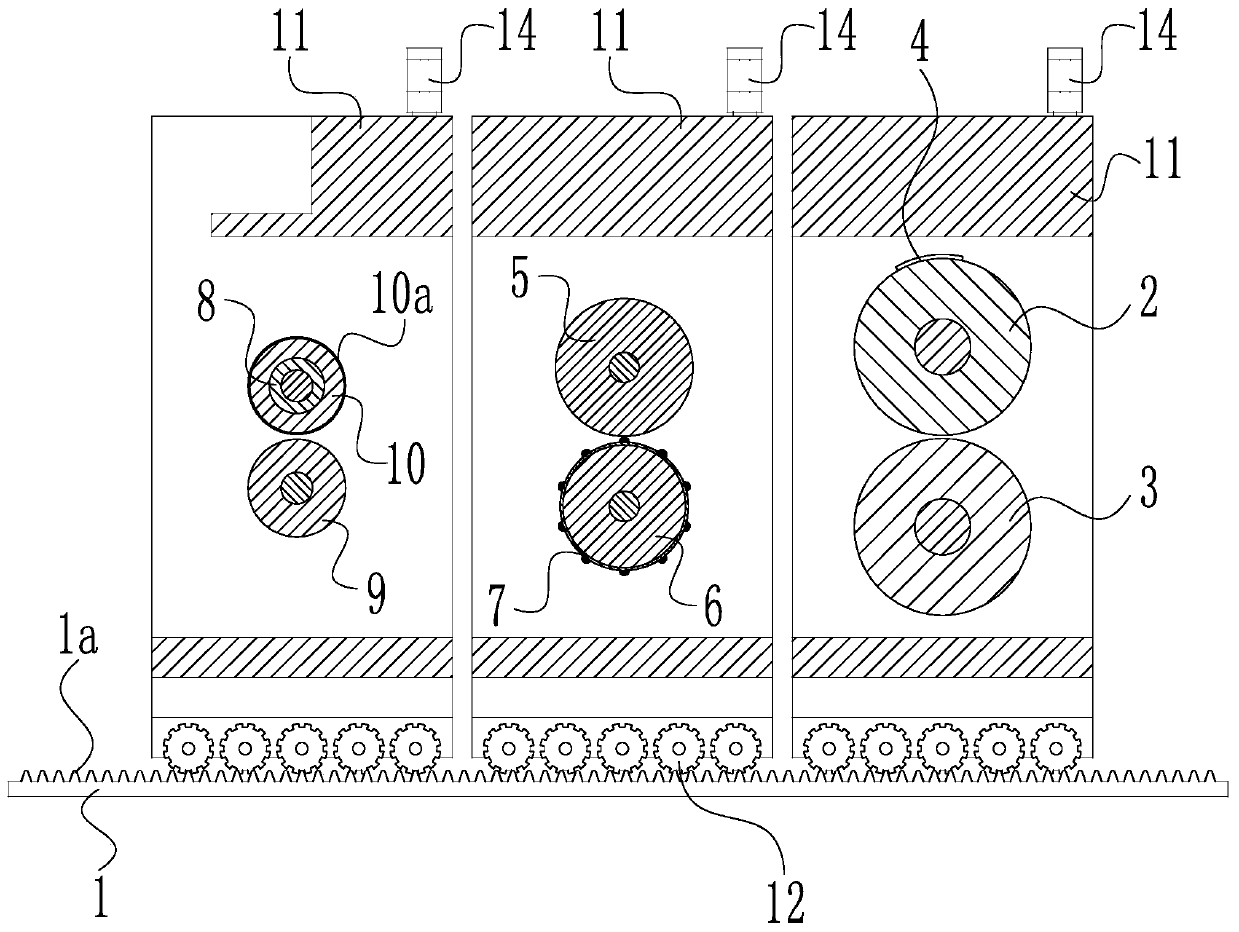

[0039] Specifically, see Figure 2 ~ Figure 4 , the ink printing slotting machine includes two ground rails 1 parallel to each other and a first-level printing module, a second-level indentation pressing module, and a third-level discharge module that can slide along the ground rails 1, and the first-level The printing module, the secondary indentation pressing module and the tertiary discharging module are arranged in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com