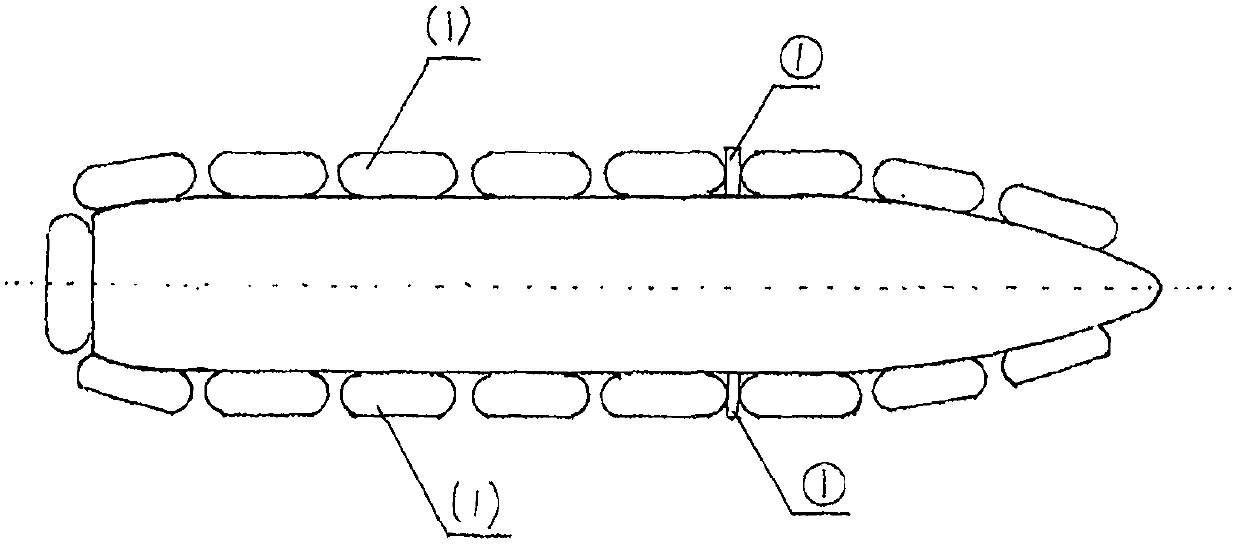

Automatic anti-sinking lifesaving system for ships

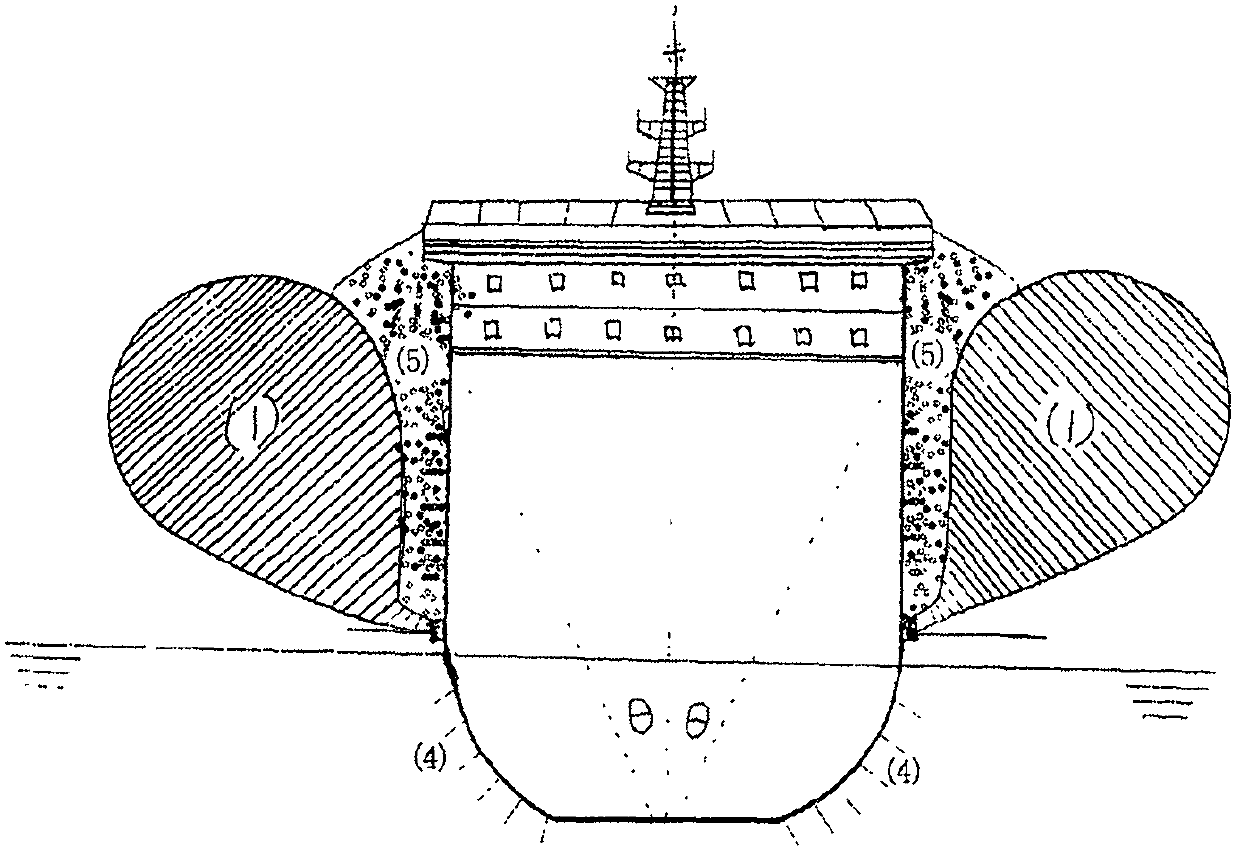

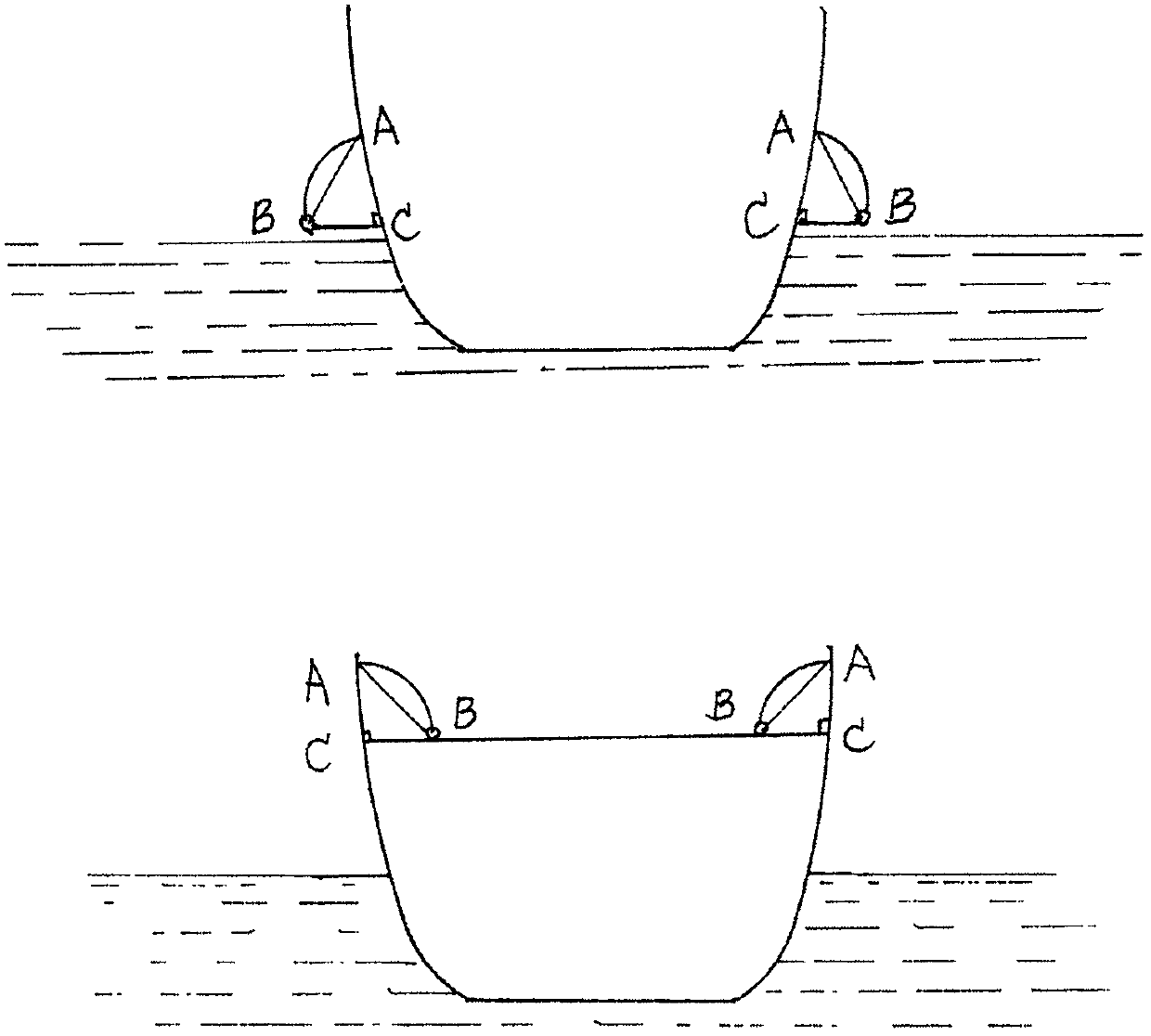

A ship and automatic technology, applied in the fields of shipbuilding, ship repair and ship accessories, can solve the problems of not preventing shipwreck accidents, increasing watertight compartments, increasing freeboard height, etc., to improve lateral stability and wind resistance, prevent Hull shaking, increase the effect of reserve buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] 1. First make a permanent floating body in the boat:

[0045] Make the inconvenient free space in the ship, the cabin partition interlayer or the place of no use value hollow. The shape and size are not limited. According to the outfitting requirements, any material can be used for the surface. If it is hollow, just inject it Low-density floating polyurethane foaming agent (referred to as PU rigid foam), making it a foam entity. If it is not hollow, directly spray a layer of PU hard foam on the surface with a high-pressure spraying machine. After foaming and hardening, it is not only anti-corrosion, heat preservation, sound insulation, but also has the best buoyancy, forming a permanent floating body. All pipe insulation layers, pipe galleries, partitions, and interlayers are also injected with foaming agents to form permanent floating objects. The fully enclosed watertight cabin that needs to be kept is also made into a simple hollow box, which is filled with PU hard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com