Floating body platform capable of carrying out underwater explosion damage test in large water area

A floating platform and underwater explosion technology, which is applied in the field of underwater explosion and damage tests, can solve problems such as cable breakage, test data acquisition errors, and many uncontrollable factors, so as to reduce impact force, reduce acquisition errors, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

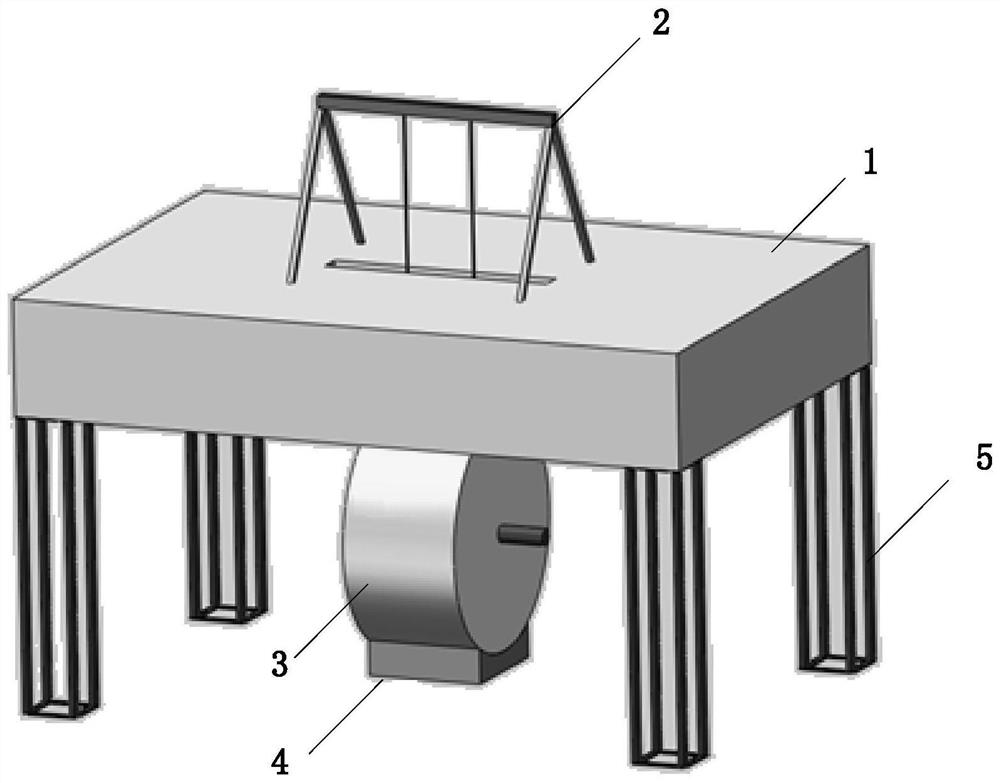

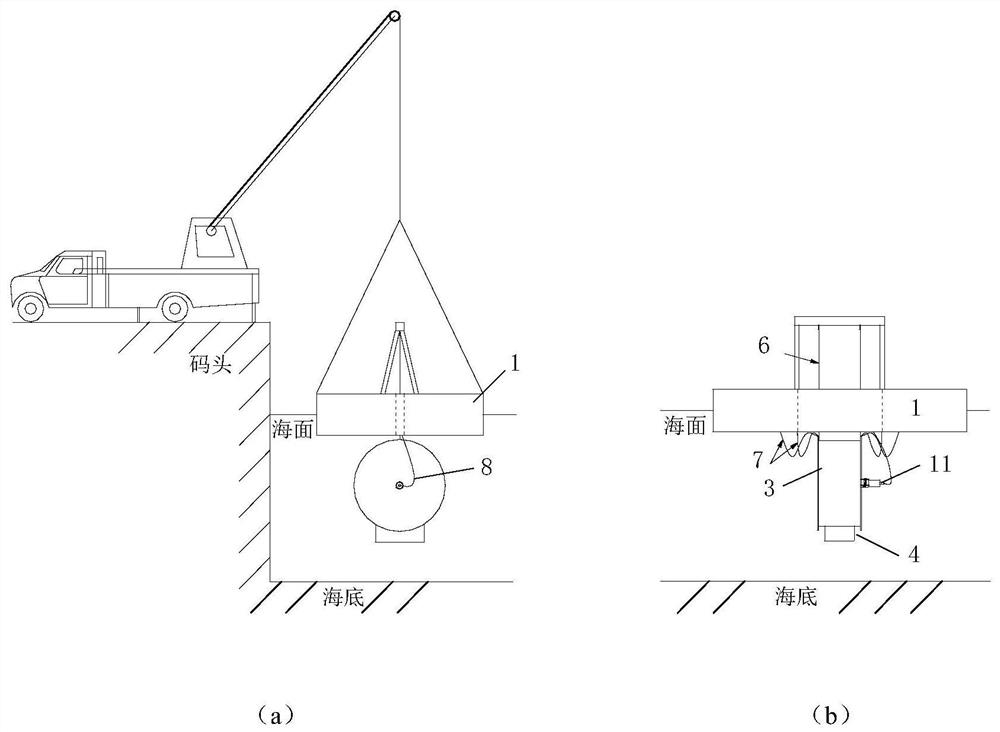

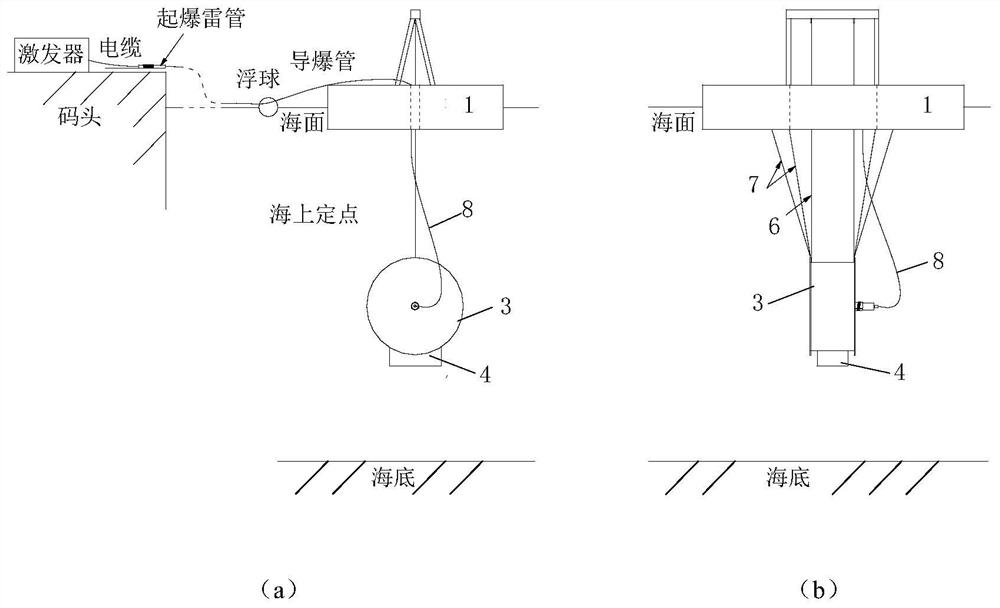

[0031] The invention provides a floating body platform capable of carrying out underwater explosion damage tests in large water areas, such as Figure 1-3 As shown, the floating body platform includes a floating body platform body 1 , a hanger 2 , an elevator, a target 3 , a ballast part 4 , an assembly base 5 , a hoisting steel cable 6 , a load-bearing steel cable 7 and a restricted detonating cord 8 .

[0032] The hanger 2 is installed in the middle of the floating body platform body 1, and one end of the hoisting steel cable 6 is fixed on the hanger, and the other end passes through the gap on the floating body platform body below the hanger to connect to the target 3. In this embodiment, a square gap is provided in the center of the floating body platform for lifting and lowering the steel cables. Elevator is used for controlling hoisting steel cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com