Cloth feeding mechanism and additional feeding mechanism of digital printing machine

A digital printing machine and additional technology, applied in printing, typewriter, thin material processing and other directions, can solve the problems of bonding and fixing product defects, affecting printing quality, inaccurate control of constant tension, etc., to achieve cost-effective and competitive Quite good, the effect of saving human, material and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

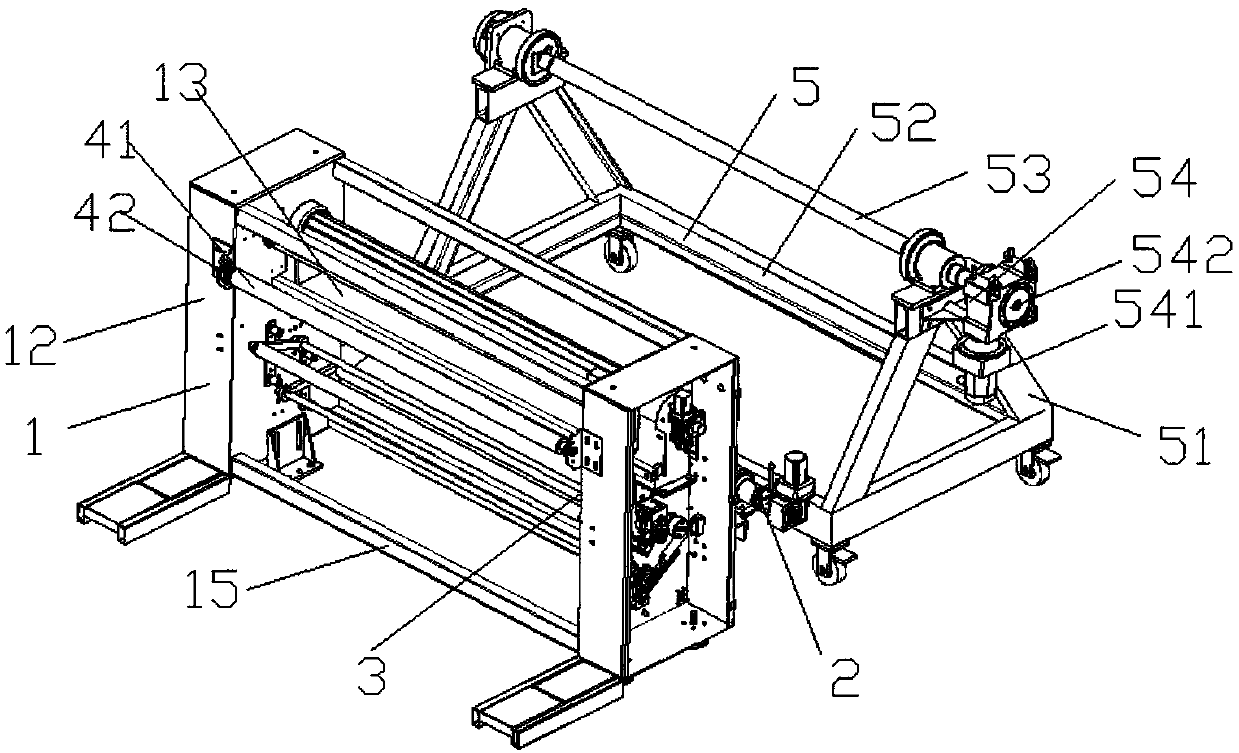

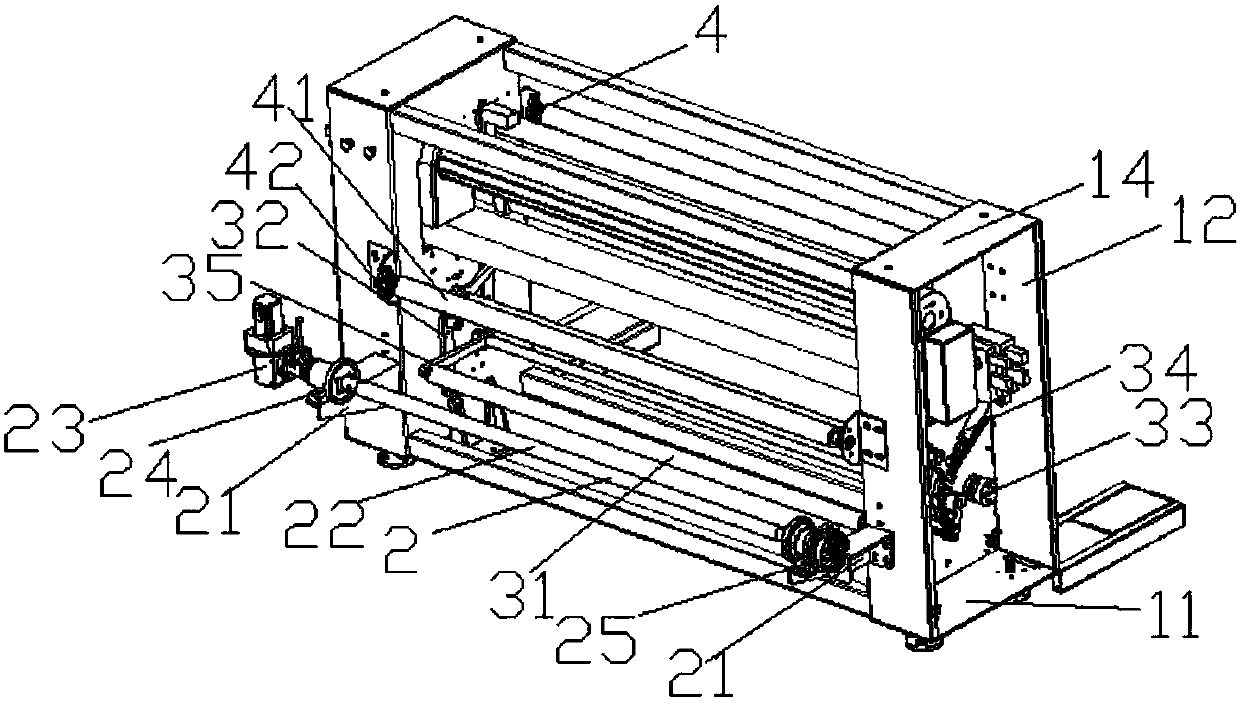

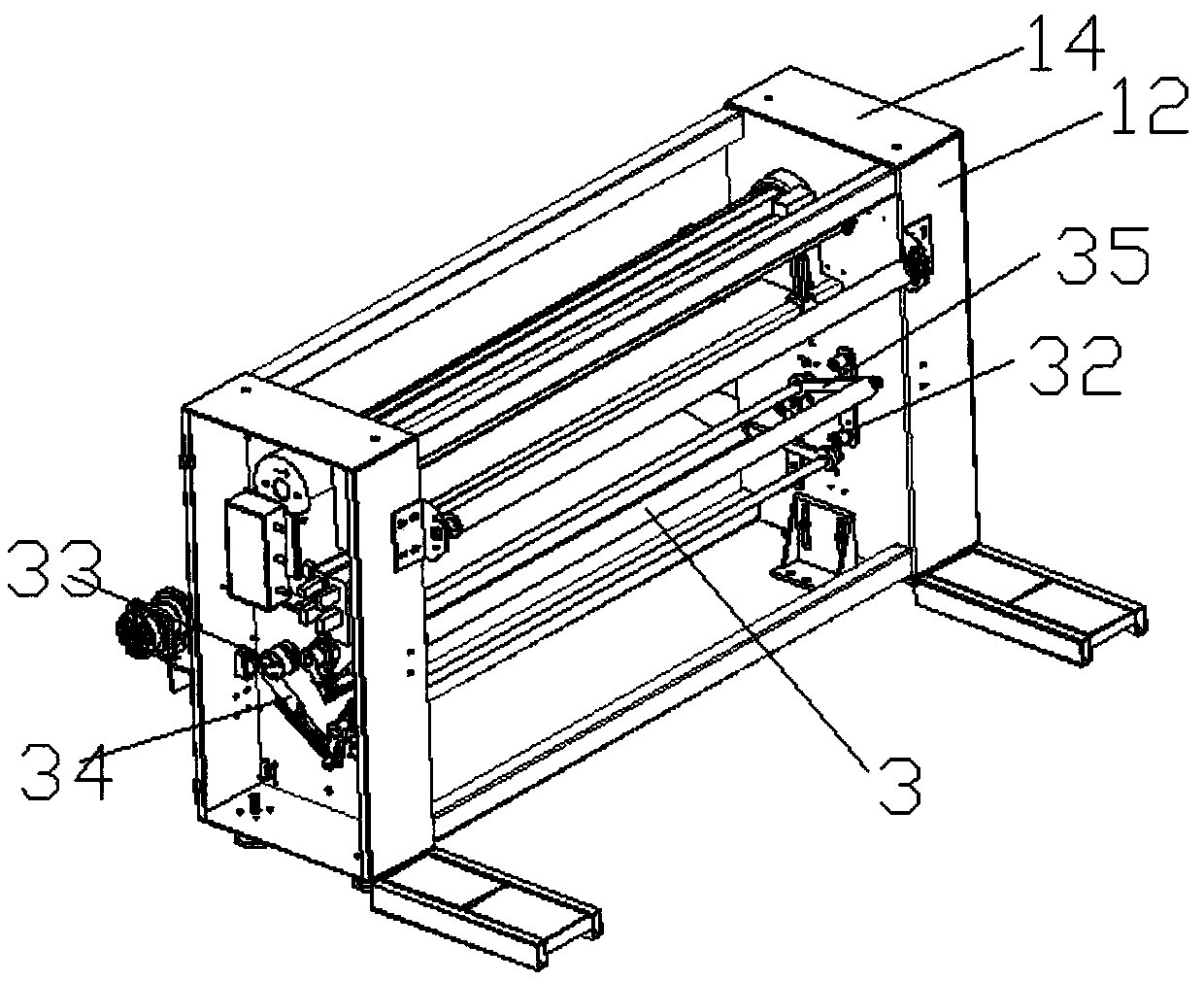

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Referring to accompanying drawing, the present invention comprises the frame 1 that is made up of bottom plate 11, side plate 12, cover 13, horizontal plate 14, square pipe 15, and frame 1 is fixed by two groups of tops by horizontal plate 14, and bottom is fixed by bottom plate 11. The connected side plate 12 is composed of a square tube 15 and a cover 13 after two groups are arranged oppositely. It is characterized in that: the frame 1 is provided with a horizontally arranged feeding mechanism 2, a constant tension mechanism 3, and a guide roller. Agency 4;

[0020] The feeding mechanism 2 is composed of a feeding mechanism base 21, an air expansion roller 22, a motor mechanism 23, a clutch 24 and a braking mechanism 25;

[0021] Described constant tension mechanism 3 is made of constant tension rotating roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com