Filling method of almagate suspension

A suspension, aluminum-magnesium plus technology, applied in the field of pharmaceuticals, can solve problems such as stickiness, difficulty in filling and sealing precise control of filling volume, and achieve the effects of accurate filling volume, not easy to leak, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

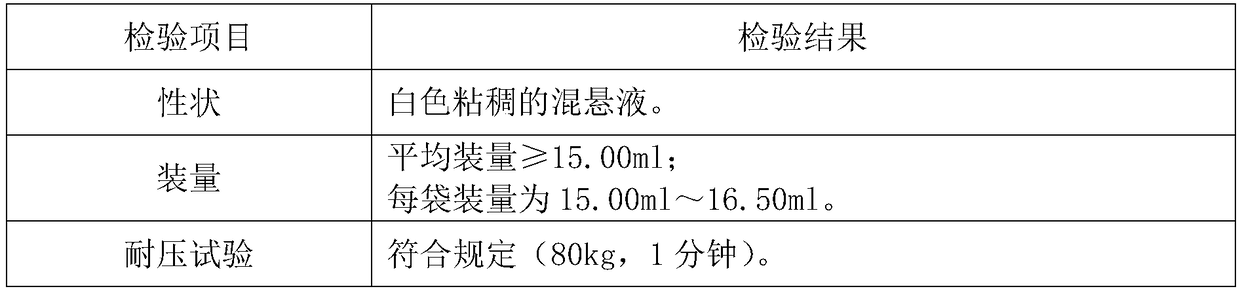

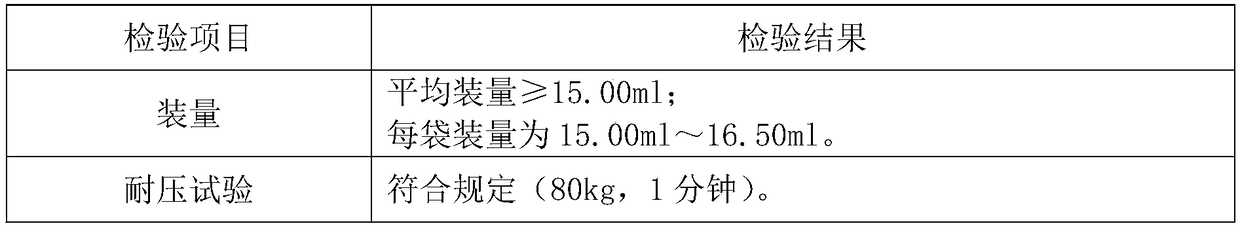

Examples

Embodiment 1

[0027] Filling of aluminum and magnesium suspension

[0028] (1) Move the feed liquid from the storage tank to the small storage tank;

[0029] (2) Open the potting and sealing machine, and the feed liquid passes through the initial feed liquid 6L of the filling port of the potting and sealing machine to be discarded;

[0030] (3) After confirming that the vertical and horizontal heating temperature of the sealing part in the filling and sealing machine reaches 160°C, turn on the ultraviolet lamp inside the machine, put the aluminum-plastic composite film into the pressure roller, and turn on the compressed air cooling device at the same time;

[0031] (4) Confirm that the length, bonding firmness, and indentation line of the aluminum-plastic composite film bag meet the regulations;

[0032] (5) Detect the relative density ρ of feed liquid, calculate the filling capacity of every bag of medicinal liquid according to the following formula: M=ρ*V; Wherein V is 15mL;

[0033] (...

Embodiment 2

[0037] Filling of aluminum and magnesium suspension

[0038] (1) Move the feed liquid from the storage tank to the small storage tank;

[0039] (2) Open the potting and sealing machine, and the feed liquid passes through the initial feed liquid 6L of the filling port of the potting and sealing machine to be discarded;

[0040] (3) After confirming that the vertical and horizontal heating temperature at the sealing part of the filling and sealing machine reaches 200°C, turn on the ultraviolet lamp inside the machine, put the aluminum-plastic composite film into the pressure roller, and turn on the compressed air cooling device at the same time;

[0041] (4) Confirm that the length, bonding firmness, and indentation line of the aluminum-plastic composite film bag meet the regulations;

[0042] (5) Detect the relative density ρ of feed liquid, calculate the filling capacity of every bag of medicinal liquid according to the following formula: M=ρ*V; Wherein V is 15mL;

[0043] (...

Embodiment 3

[0048] Filling of aluminum and magnesium suspension

[0049] (1) Move the feed liquid from the storage tank to the small storage tank;

[0050] (2) Open the potting and sealing machine, and the feed liquid passes through the initial feed liquid 6L of the filling port of the potting and sealing machine to be discarded;

[0051] (3) After confirming that the vertical and horizontal heating temperature at the sealing part of the filling and sealing machine reaches 180°C, turn on the ultraviolet lamp inside the machine, put the aluminum-plastic composite film into the pressure roller, and turn on the compressed air cooling device at the same time;

[0052] (4) Confirm that the length, bonding firmness, and indentation line of the aluminum-plastic composite film bag meet the regulations;

[0053] (5) Detect the relative density ρ of feed liquid, calculate the filling capacity of every bag of medicinal liquid according to the following formula: M=ρ*V; Wherein V is 15mL;

[0054] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com