Edge cutting and edgings discharge device for embroidery machinery

A technology of exporting device and embroidery machine, applied in embroidery machine, embroidery machine mechanism, auxiliary device and other directions, can solve the problems of wasting time and labor cost, edge trimming equipment failure, winding and other problems, and achieves convenient connection, easy disassembly and assembly, Avoid the effect of position shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings.

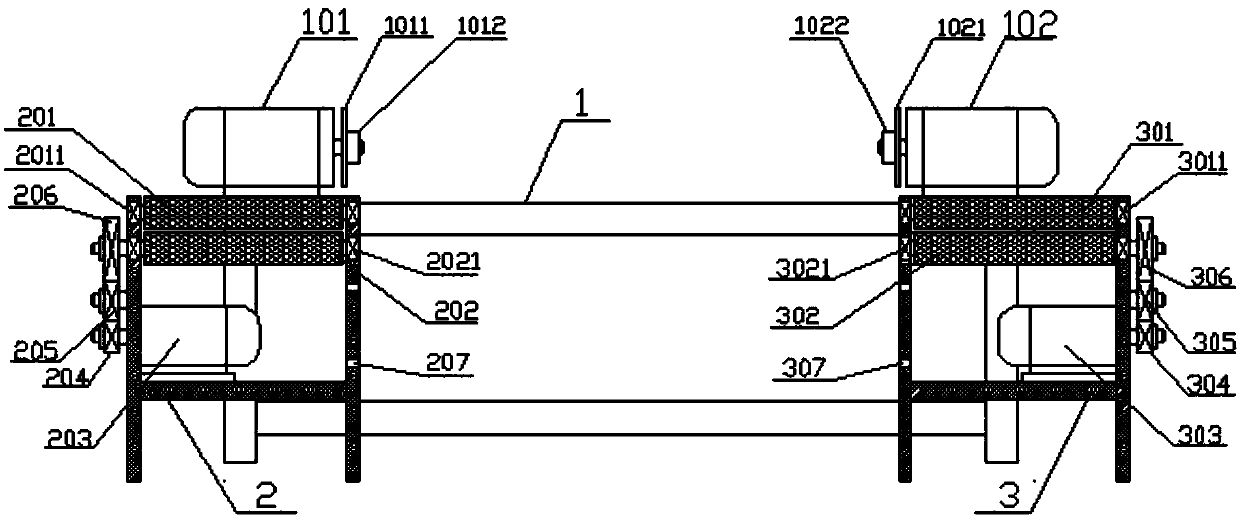

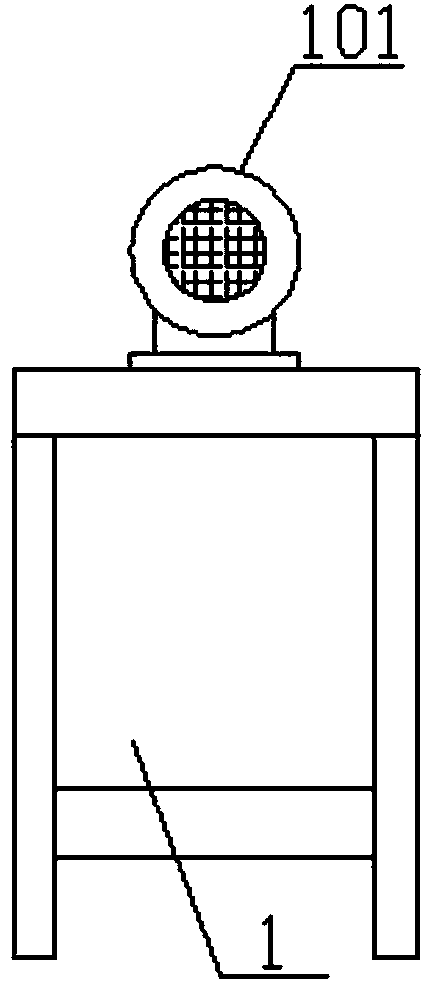

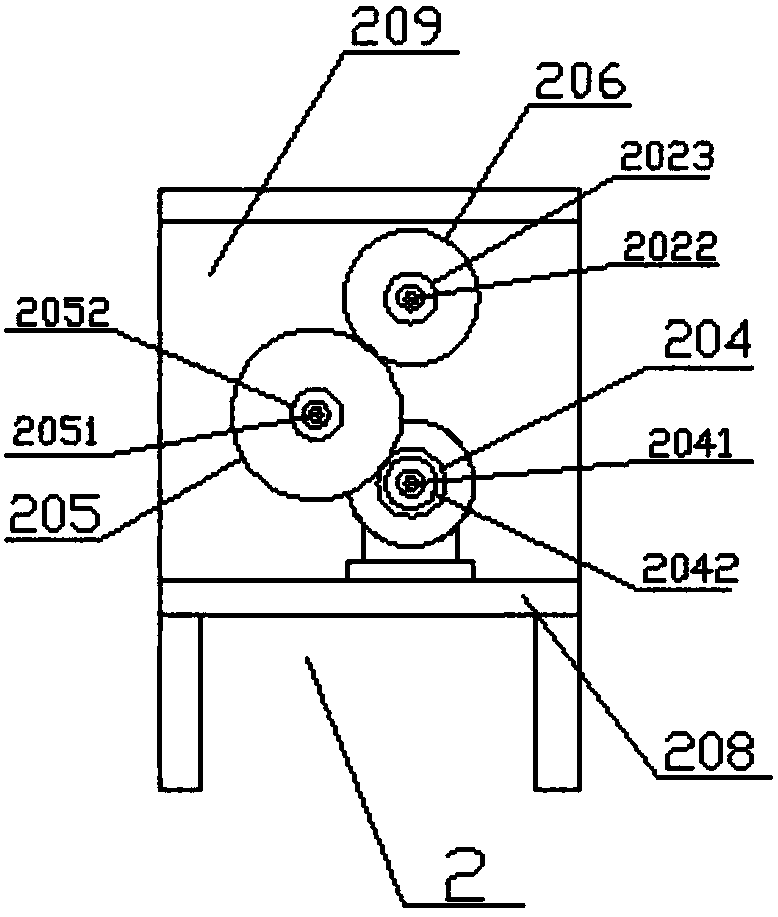

[0018] Such as Figure 1 ~ Figure 6 As shown, the edge trimming and edge strip leading-out device of the embroidery machine includes trimming frame 1, left leading-out device 2, right leading-out device 3, and both sides of the upper end of the trimming frame 1 are provided with a motor 101 and a motor 102 respectively. The first motor 101 shaft is provided with a cutter head 1011, and an external nut 1011 is used for locking, the motor second 102 shaft is provided with a cutter head two 1021, and the external nut two 1022 is used for locking. The left lead-out device 2 is provided with a number of fixing holes on the right side. One 207, a pressure roller 201 is set on the top, a roller 202 is set on the bottom, a platform 208 is set in the middle, and a side plate 209 is set on the left side. The two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com