Counterforce structure for transverse deviation rectification of ballastless track of roadbed section and manufacturing method thereof

A technology of ballastless track and manufacturing method, which is applied in the direction of track, track laying, track maintenance, etc., can solve problems affecting track smoothness, ballastless track structure deviation disease, complex and changeable environmental conditions, etc., to achieve convenient operation, The effect of high stability and flexible application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

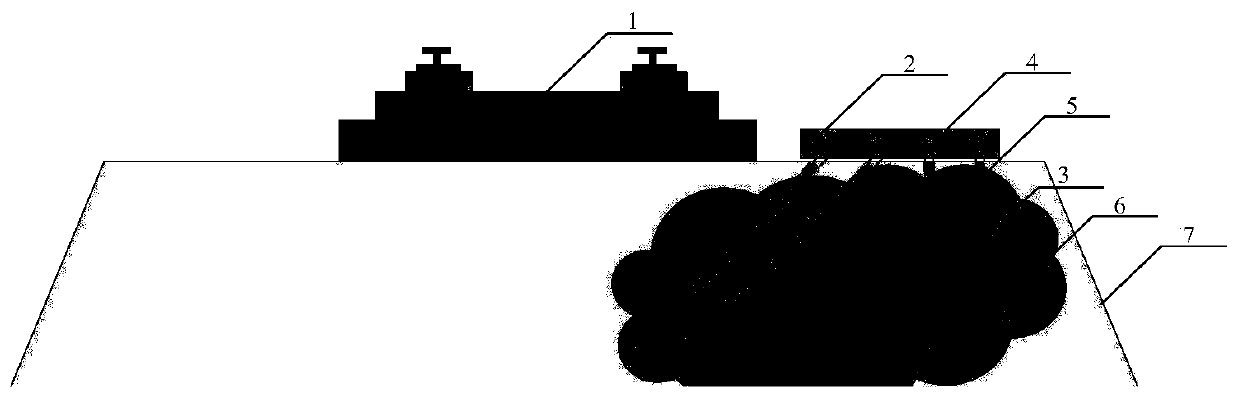

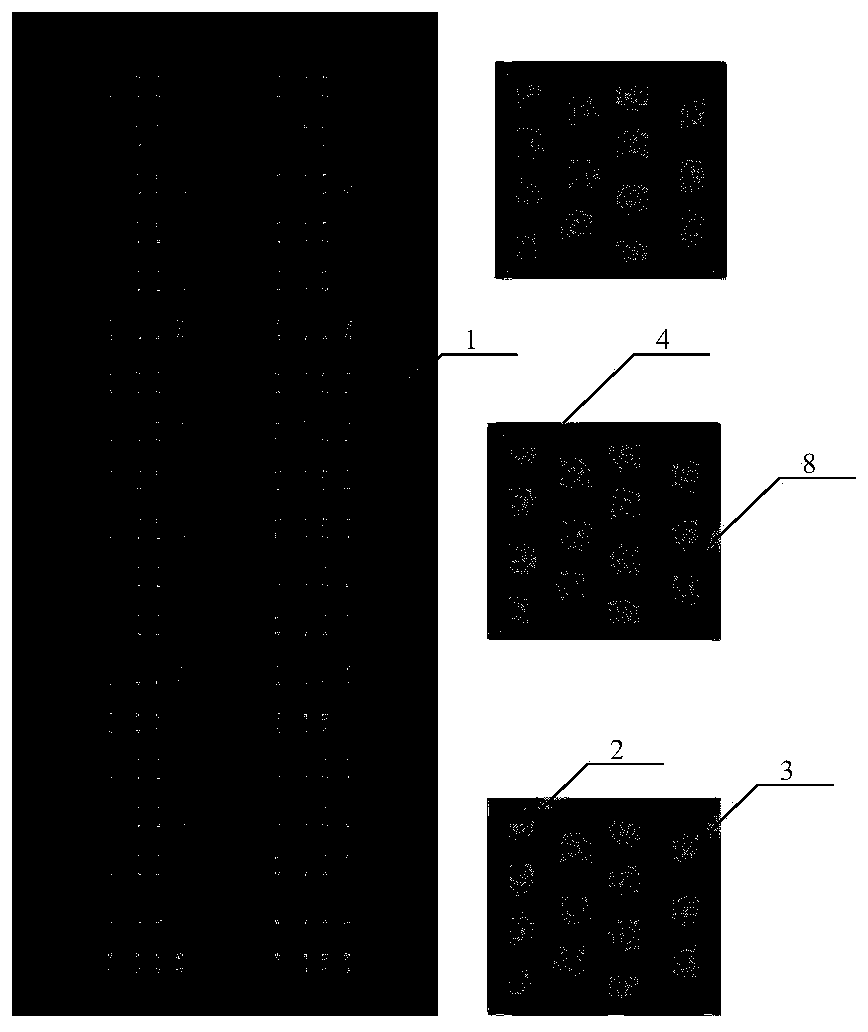

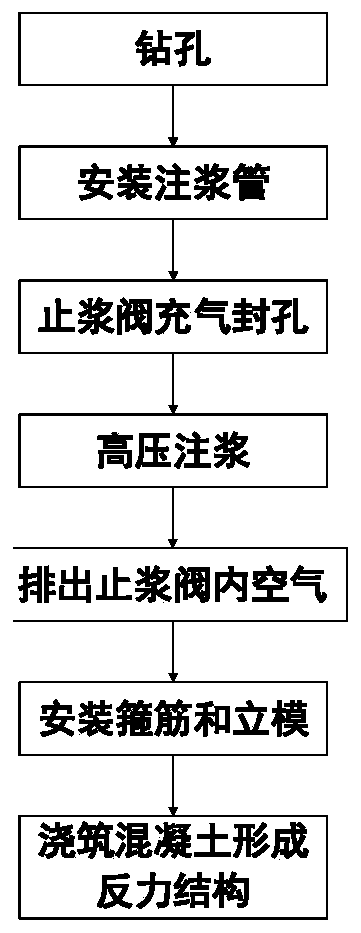

[0032] A method for manufacturing a reaction force structure for lateral deviation correction of ballastless track structures in conventional sections of subgrade sections, the method is used for deviation correction operations of ballastless track structures on operating lines, and mainly includes the following steps:

[0033] Step 1: Start the down-the-hole drill to drill the hole. The diameter of the hole is 30mm. It is divided into 4 rows along the line. The holes in each row are arranged in a plum blossom shape. The first and third rows are 4 grouting pipes. The second and third rows are three grouting pipes. The first row of holes is 300mm away from the ballastless track structure. The direction is 45°, oblique to the center of the line, the drilling depth is 3m, and the drilling depth of the straight hole is 2m;

[0034]Step 2: Install the grouting pipe, first install the oblique grouting pipe into the grouting hole, use an air compressor to inflate the grout valve, the...

Embodiment 2

[0039] A method for making a reaction force structure for lateral deviation correction of ballastless track structures in turnout areas, the method is used for deviation correction operations of ballastless track structures in turnout areas of operating lines, and mainly includes the following steps:

[0040] Step 1: Start the down-the-hole drill to drill the hole. The diameter of the hole is 30mm. It is divided into 4 rows of holes along the line. The holes in each row are arranged in a plum blossom shape. The length of each row of holes along the line is the length of the correction section. , the first row of holes is 300mm away from the ballastless track structure, the two rows of holes close to the line are inclined holes, the two rows of holes away from the line are vertical holes, the inclined holes are 40° from the horizontal direction, inclined to the center of the line, and the drilling depth 3m, straight hole drilling depth is 2m;

[0041] Step 2: Install the grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com