Reinforced concrete prefabricated overall-poured house structure and construction method thereof

A technology of reinforced concrete and houses, which is applied in the direction of building structure and construction, can solve the problems of poor connection stability between floor and wall panels, and achieve the goals of improving convenience and precision, improving the stability of fixed connections, and improving assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

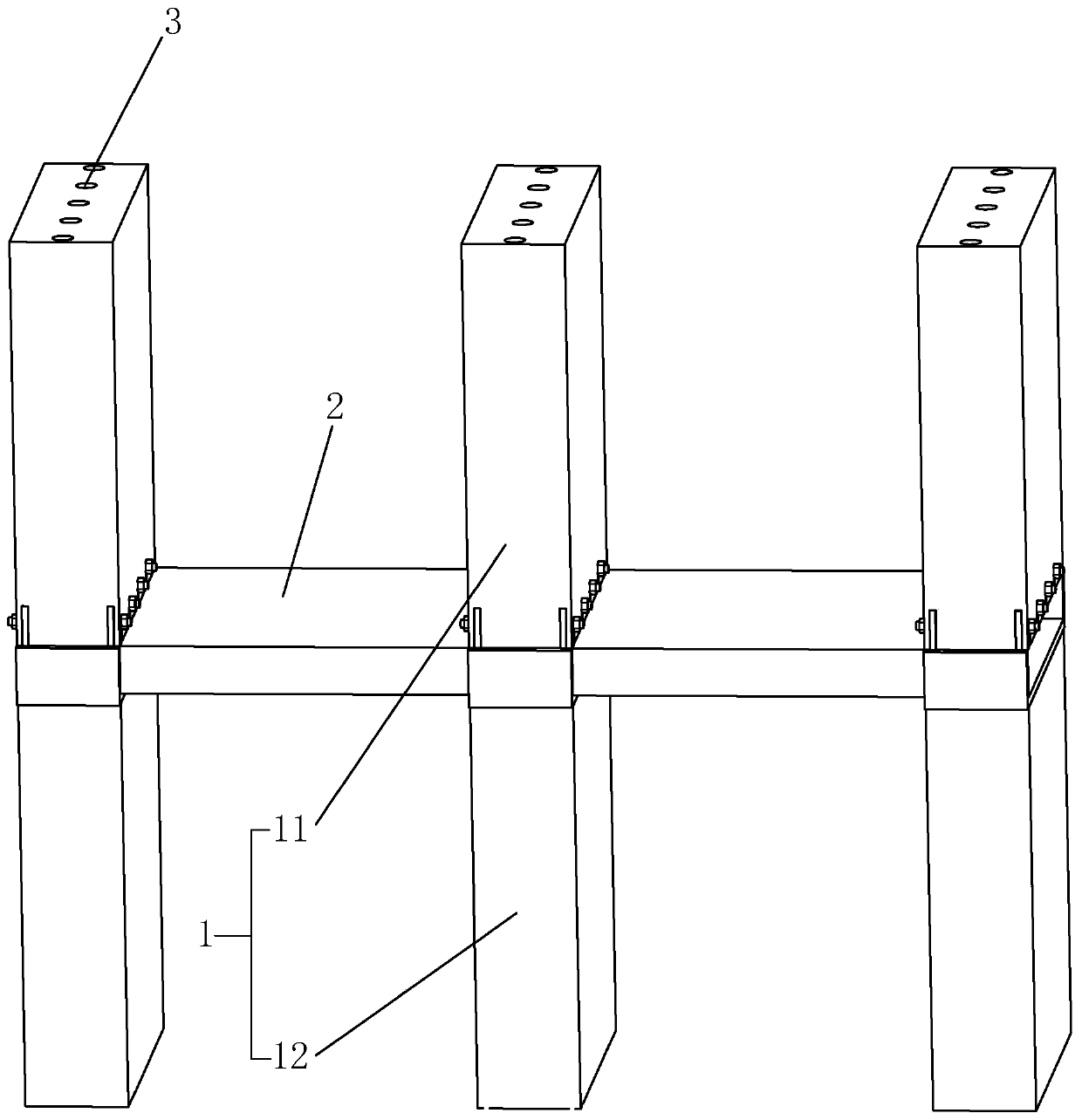

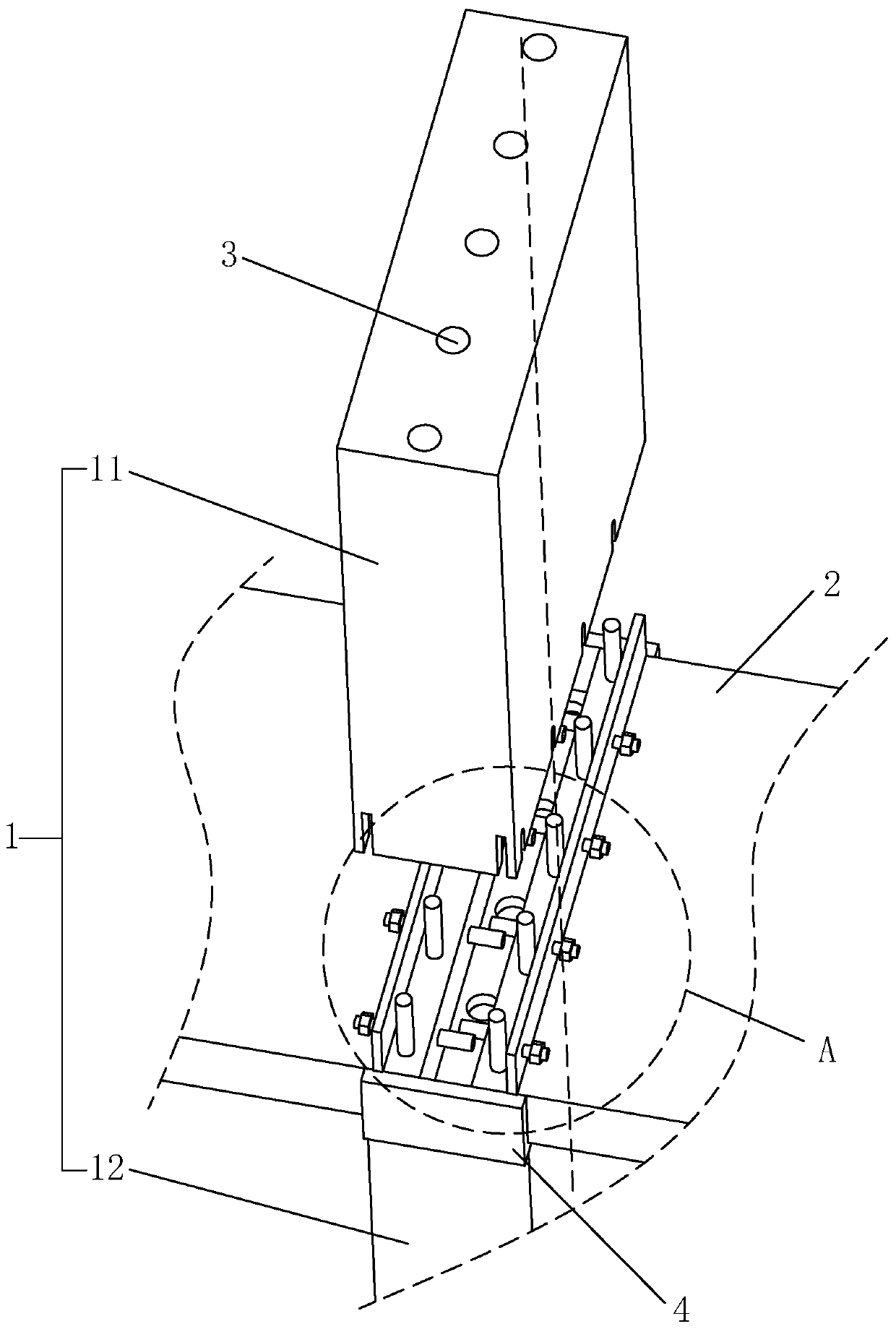

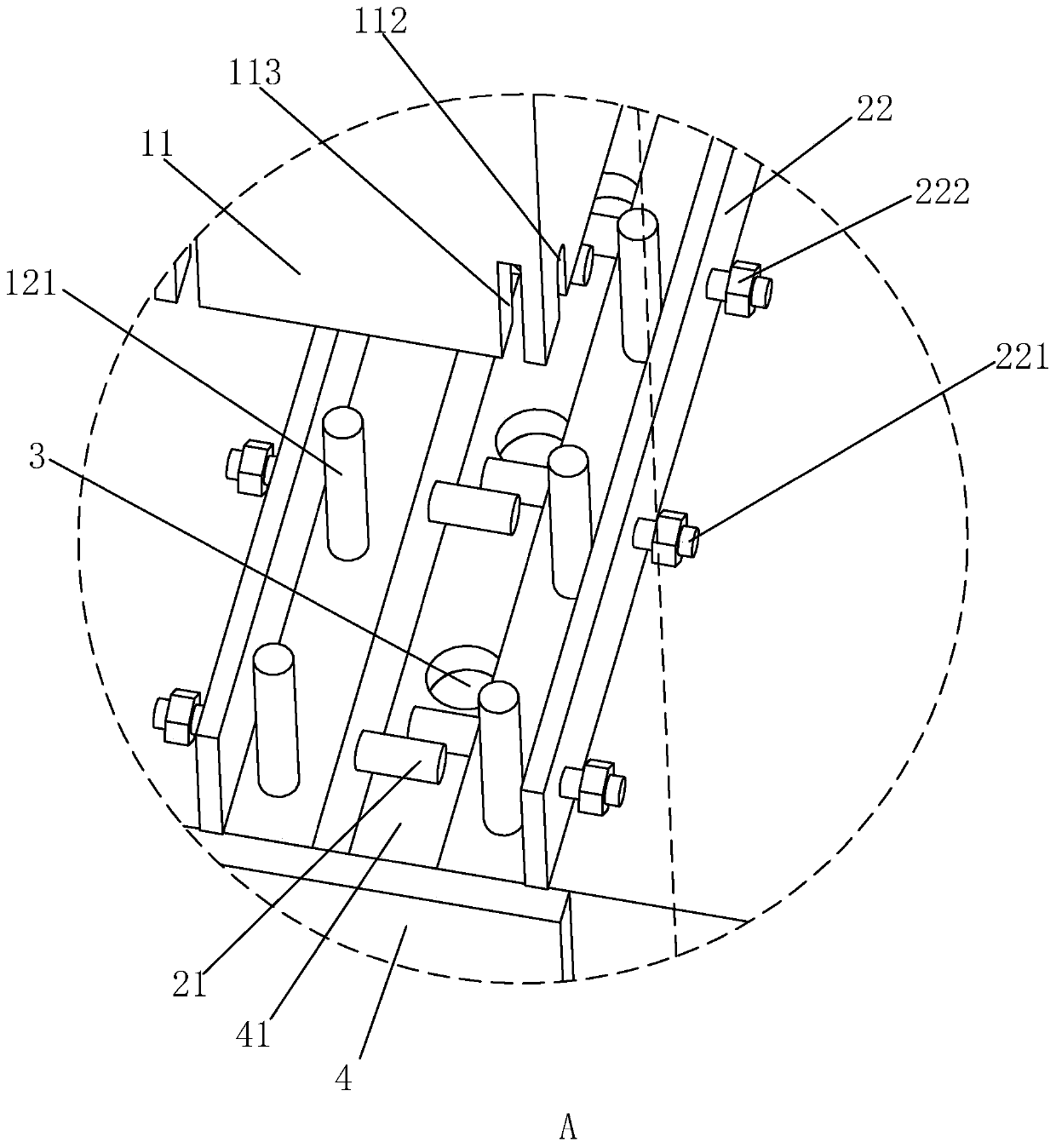

[0040] A reinforced concrete prefabricated integral pouring house structure and its construction method, such as figure 1 and image 3 As shown, it includes a wall panel 1 and a floor slab 2. The wall panel 1 includes an upper wall 11 and a lower wall 12. The lower wall 12 is directly fixed to the ground and perpendicular to the ground during prefabrication. The lower wall 12 includes spaced apart Multiple floor slabs 2 are also provided with multiple floor slabs 2, and the tops of every two adjacent lower walls 12 are erected with a floor slab 2. In the gap, the upper wall 11 is located directly above the lower wall 12 and the upper wall 11 and the lower wall 12 are parallel to each other, and the upper wall 11 and the lower wall 12 are provided with a plurality of pouring holes 3 vertically penetrating themselves. The bottom of the upper wall 11 abuts against the end positions of two adjacent floor slabs 2. The upper surface of the floor slabs 2 is fixedly provided with a p...

Embodiment 2

[0047] A construction method for a reinforced concrete prefabricated cast-in-place house structure, the specific method of which is as follows:

[0048] S1: The floor 2 and wall 1 are prefabricated. The steel bars at both ends of the floor 2 pass through the floor 2 horizontally to form connecting steel bars 21. The steel bars at both ends of the floor 2 pass through the floor 2 vertically to form fixed steel bars 121. During prefabrication, direct pouring is fixed connection with the ground;

[0049] S2: Put the floor 2 in the installation groove 41 at the top of the lower wall 12, so that there is a gap between the two adjacent floors 2 at the top of the same lower wall 12 close to each other, and then place the adjacent floors 2 The connecting steel bars 21 are welded together;

[0050] S3: Move the prefabricated upper wall 11 to the top of the floor 2 through hoisting, and the upper wall 11 is located directly above the lower wall 12, so that the fixed steel bar 121 is fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com