Engineering machinery equipment data remote monitoring system

A remote monitoring system and equipment data technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high misoperation rate, slow measurement process, large reading error, etc., to break through geographical restrictions, facilitate quality management, improve The effect of management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

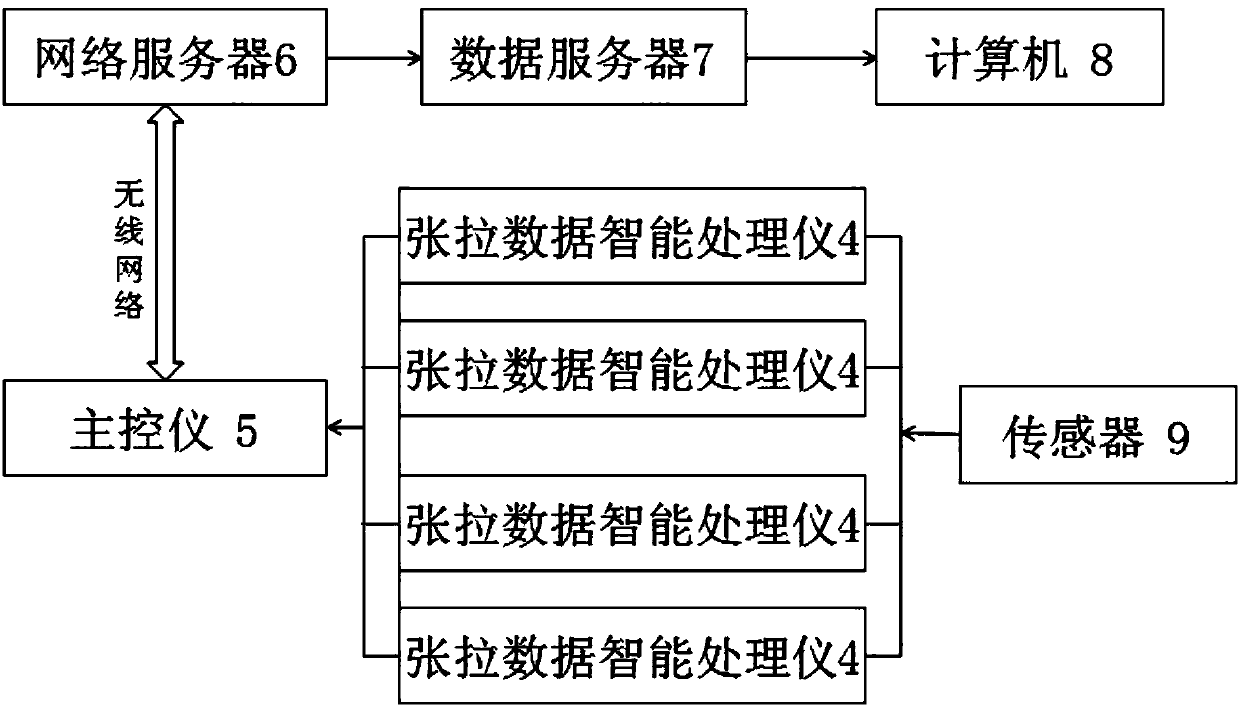

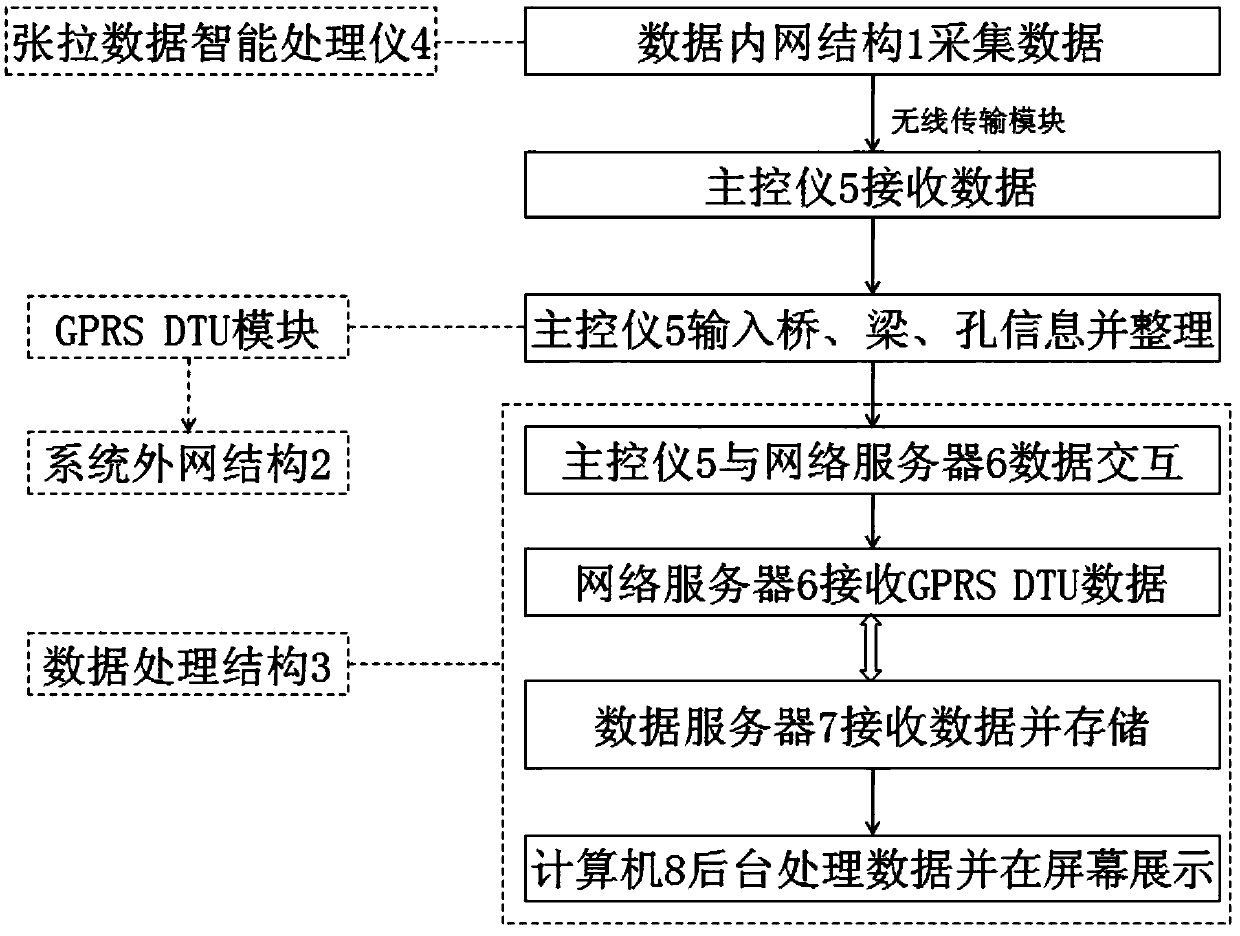

[0032] Such as Figure 1-2 A remote monitoring system for construction machinery and equipment data is shown, including a data intranet structure 1, which is used to collect data during the entire system's working process;

[0033] The system external network structure 2 is used to transmit the data collected by the data internal network structure 1;

[0034] Data processing structure 3, used for data processing and display;

[0035] The data intranet structure 1 includes several stretching data intelligent processors 4;

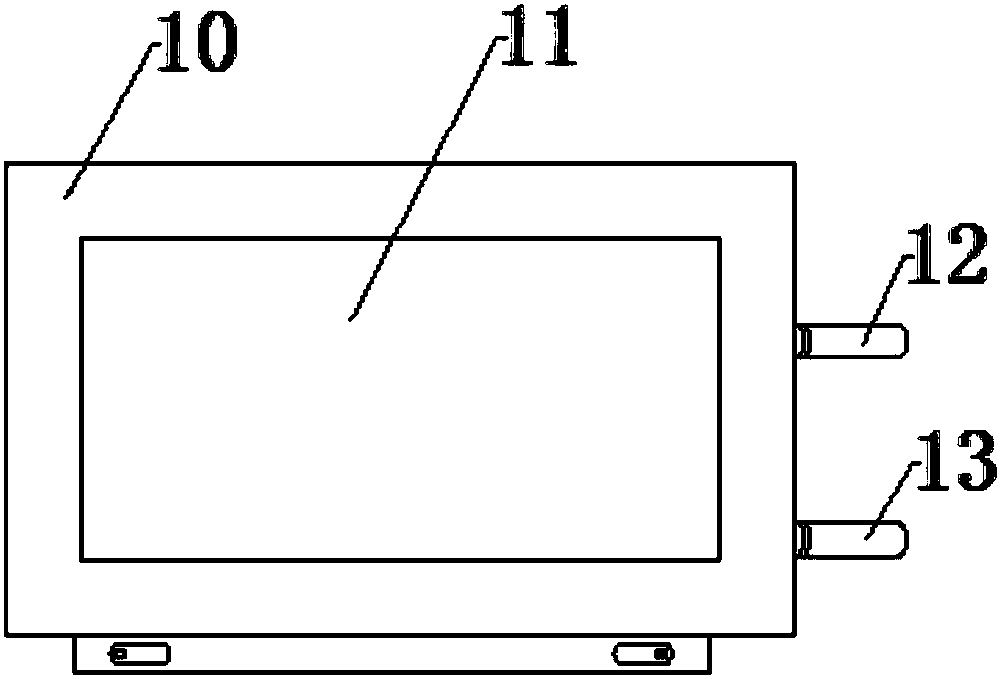

[0036] Further, the external network structure 2 of the system includes a GPRS DTU module embedded in the main control instrument 5; the main control instrument 5 adopts a 7-inch large screen for data input according to the site environment and operation requirements, which greatly improves the basic information of the bridge. The input efficiency is also made of aluminum alloy withholding structure.

[0037] Further, the data processing structure 3 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com