Proton exchange membrane fuel cell bipolar plate three-dimensional flow field

A proton exchange membrane, fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems affecting cell performance, large resistance of diffusion layer, large gas pressure drop, etc. , The effect of simplifying the battery system and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

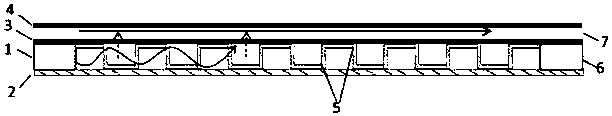

[0027] Such as figure 1 and 2 The schematic diagram of the three-dimensional flow field of the fuel cell bipolar plate with the function of baffle and water separation is shown, in which the three-dimensional flow field structure is formed by perforating and bending on a CNC punching machine to form the bending process of the perforated plate, specifically:

[0028] The three-dimensional flow field is located between the membrane electrode and the separator to form a sealed structure. The end surface of the flow channel is one or more tooth-shaped, and fluid holes are opened between the tooth root and the tooth top on both sides of each tooth.

[0029] The tooth-shaped end face is square. The teeth in the flow field are alternately arranged with convex and concave structures, forming the ridges and flow channels of the three-dimensional flow field.

[0030] The distance between the dedendum and the dedendum is 0.4mm, and the distance between any two adjacent dedendums or ded...

Embodiment 2

[0034] Such as image 3 and 4 A schematic diagram of the structure of the fluid holes in different directions of the three-dimensional flow field is shown, in which the three-dimensional flow field structure adopts the punching process of the perforated plate, specifically:

[0035] The three-dimensional flow field is located between the membrane electrode and the separator to form a sealed structure. The end surface of the flow channel is one or more tooth-shaped, and fluid holes are opened between the tooth root and the tooth top on both sides of each tooth.

[0036] The tooth-shaped end surface is an isosceles trapezoid. The teeth in the flow field are alternately arranged with convex and concave structures, forming the ridges and flow channels of the three-dimensional flow field.

[0037] The distance between the dedendum and the dedendum is 0.5mm, and the distance between any two adjacent dedendums or dedendums is 0.8mm (vertical distance); the diameter of the fluid hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com