Split type stator forming tool

A molding tooling, split technology, applied in the field of machinery, can solve the problems of large volume and large volume of the servo motor, achieve the effect of simple structure, guarantee productivity, and ensure 100% qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

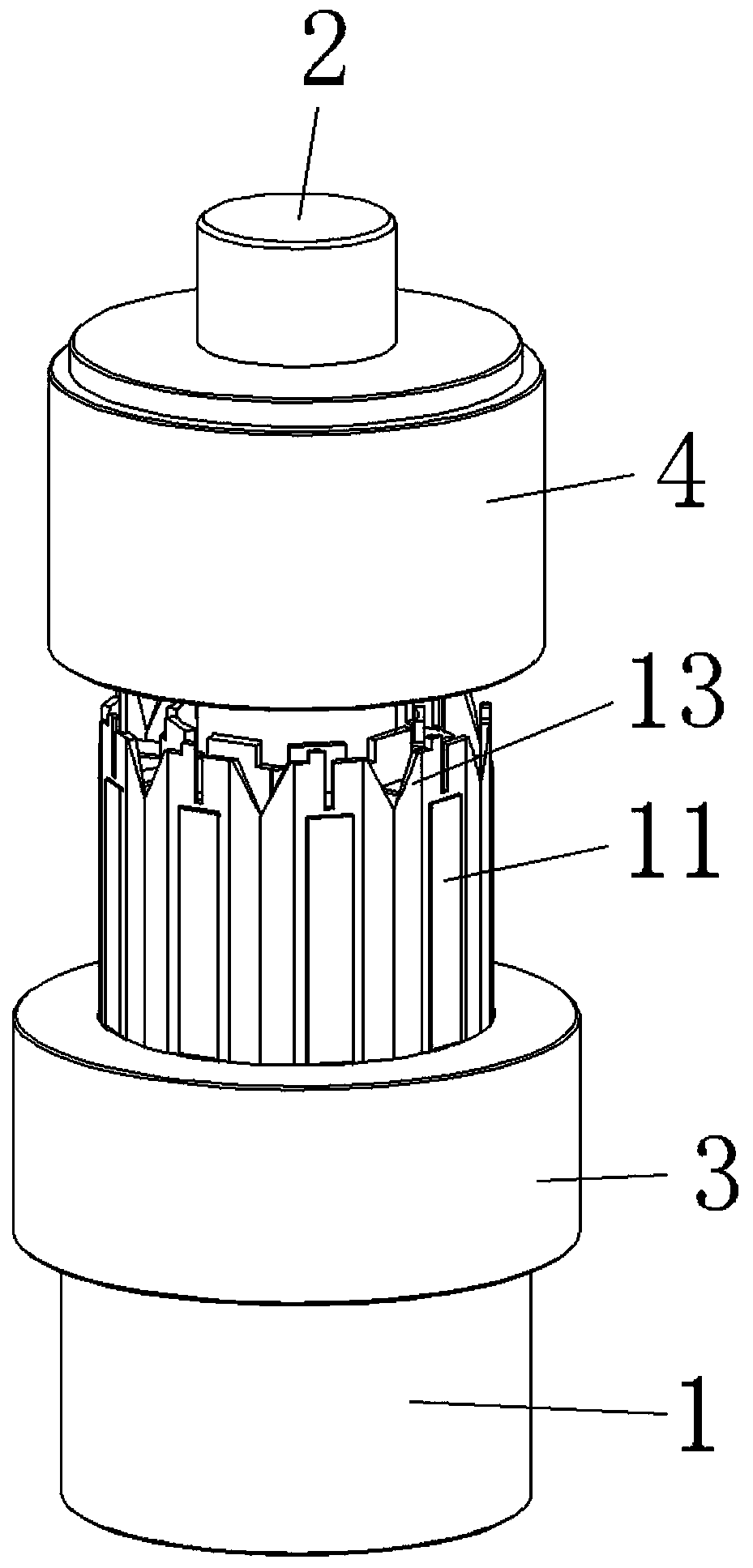

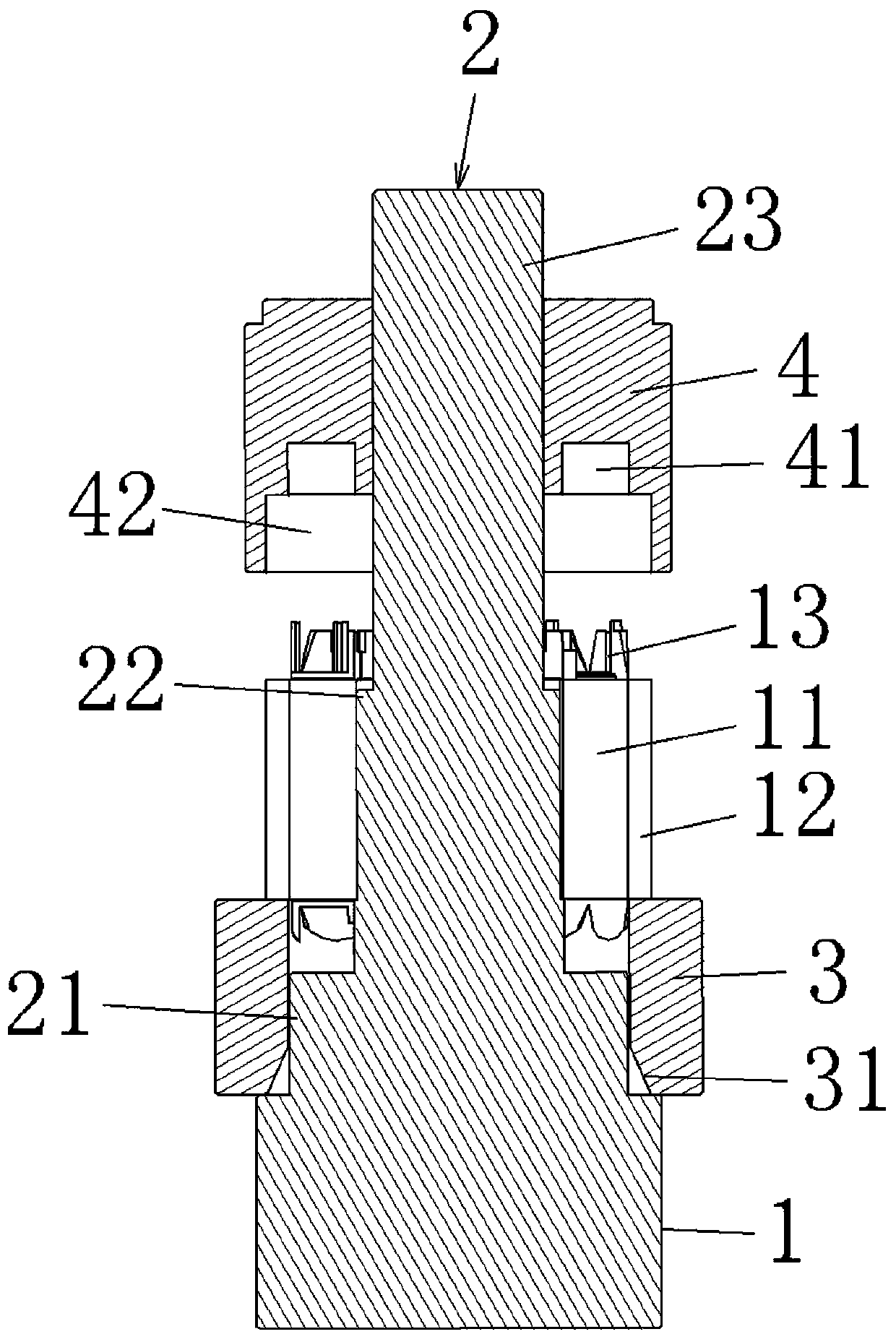

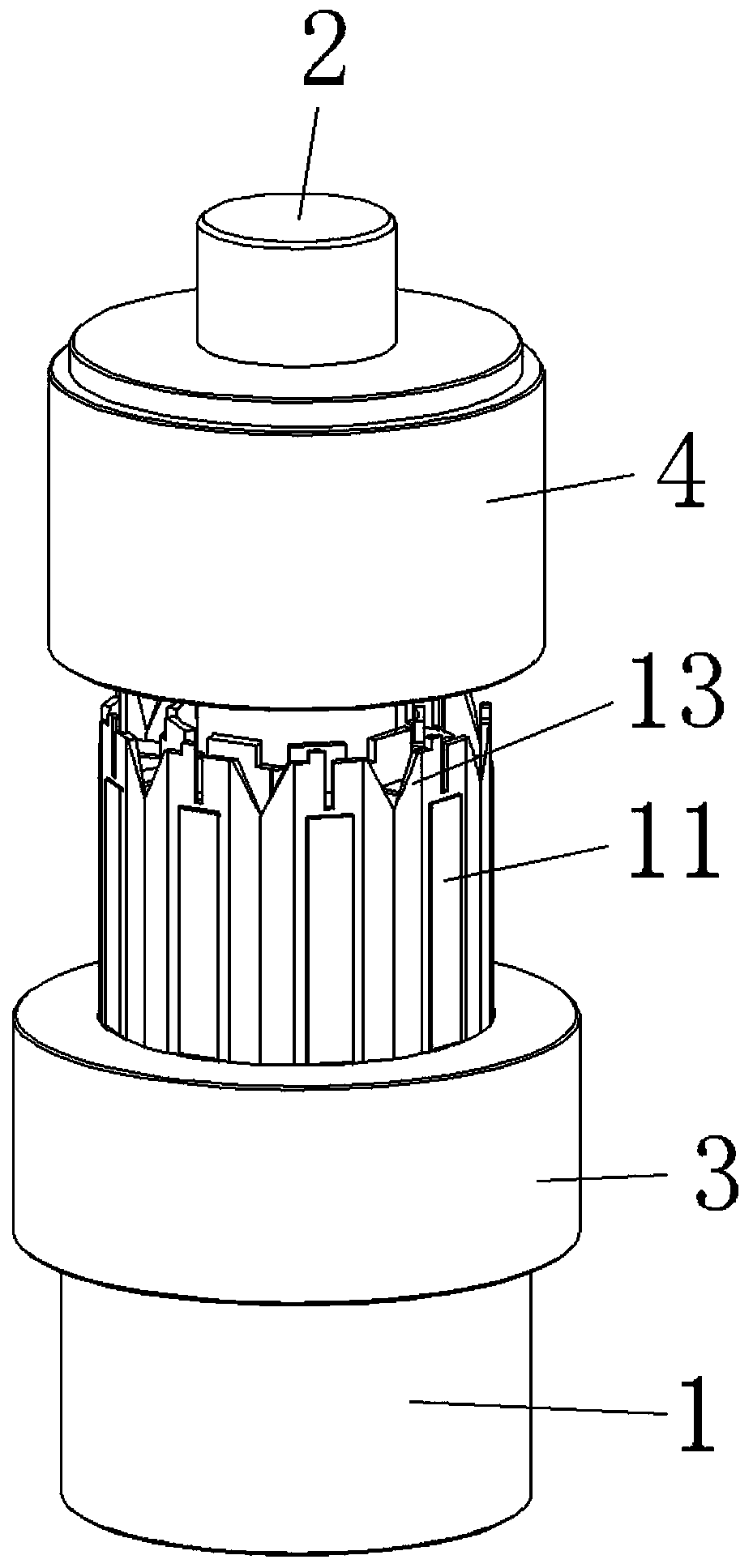

[0018] This split stator forming tooling, such as figure 2 As shown, the split stator includes an inner ring 11, a skeleton 13 for winding enameled wire and an outer ring 12, wherein figure 1 The outer ring 12 is not shown. Such as figure 1 As shown, the split-type stator forming tooling includes a cylindrical base 1, a mandrel 2 vertically arranged at the center of the base 1, a cushion mold 3 and a lower die 4 that are sequentially set on the outside of the mandrel 2, because the base 1 The weight is heavy and plays a stabilizing role. The mandrel 2 is used to put the split stator wound with enameled wires, and acts as a guide for it. The upper end of the cushion mold 3 is a plane, and the outer ring 12 can stably res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com