Molding method of chew type pet food

A technology of pet food and molding method, which is applied in the field of pet food, can solve the problems of low production efficiency, easy adhesion to molds, low product bite resistance, etc., and achieve the effects of improving production efficiency, ensuring quality, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

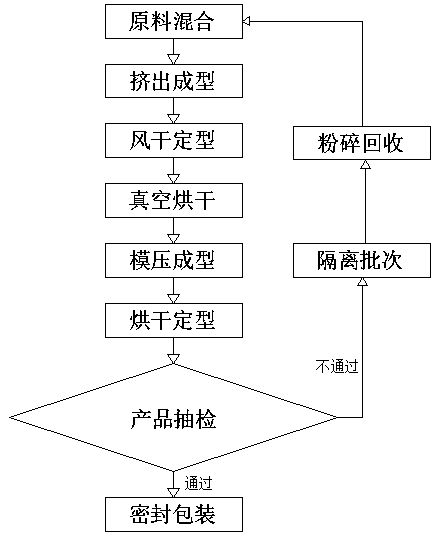

[0025] Embodiment 1, with reference to figure 1 , a molding method for chewing pet food, comprising the following steps:

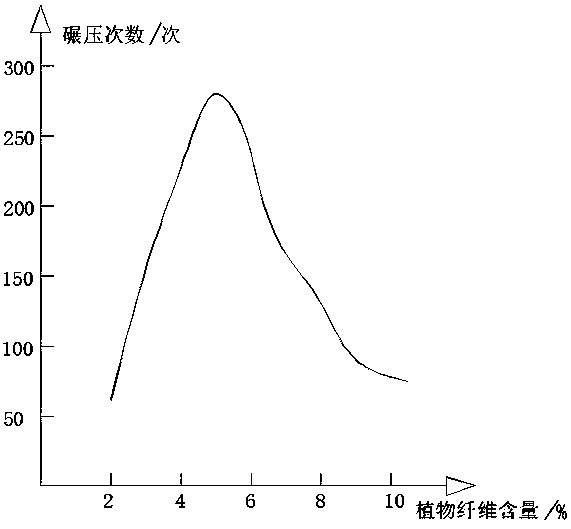

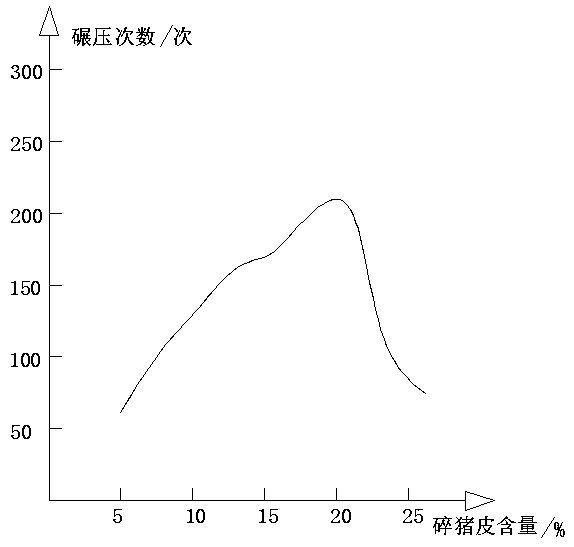

[0026] S1: Raw materials are mixed according to 16% of edible glue, 20% of shredded pigskin, 40% of shredded cowhide, 4% of vegetable protein, 10% of moisturizing agent, 2% of plant fiber and 5% of additives. Internal mixer is mixed into mud, obtains raw material mud A;

[0027] S2: extrusion molding, and then put the raw material A into the food extruder, and extrude it into rubber strips;

[0028] S3: Air-drying and setting, place a blower device at the outlet of the food extruder, and air-dry the extruded rubber strip;

[0029] S4: Vacuum drying, and then place the strips in a vacuum oven for drying until the moisture content reaches 31-33%, and the drying temperature is controlled between 53°C and 75°C;

[0030] S5: Molding, molding the rubber strip after vacuum drying to obtain a semi-finished product B;

[0031] S6: drying and shaping, and then p...

Embodiment 2

[0035] Embodiment 2, with reference to figure 1 , a molding method for chewing pet food, comprising the following steps:

[0036] S1: Raw materials are mixed according to 16% of edible glue, 20% of shredded pigskin, 40% of shredded cowhide, 4% of vegetable protein, 10% of moisturizing agent, 4% of plant fiber and 5% of additives, mixed by chopping machine, and passed Internal mixer is mixed into mud, obtains raw material mud A;

[0037] S2: extrusion molding, and then put the raw material A into the food extruder, and extrude it into rubber strips;

[0038] S3: Air-drying and setting, place a blower device at the outlet of the food extruder, and air-dry the extruded rubber strip;

[0039] S4: Vacuum drying, and then place the strips in a vacuum oven for drying until the moisture content reaches 31-33%, and the drying temperature is controlled between 53°C and 75°C;

[0040] S5: Molding, molding the rubber strip after vacuum drying to obtain a semi-finished product B;

[00...

Embodiment 3

[0045] Embodiment 3, with reference to figure 1 , a molding method for chewing pet food, comprising the following steps:

[0046] S1: Raw materials are mixed according to 16% of edible glue, 20% of shredded pigskin, 40% of shredded cowhide, 4% of vegetable protein, 10% of moisturizing agent, 6% of plant fiber and 5% of additives, mixed by chopping machine, and passed Internal mixer is mixed into mud, obtains raw material mud A;

[0047] S2: extrusion molding, and then put the raw material A into the food extruder, and extrude it into rubber strips;

[0048] S3: Air-drying and setting, place a blower device at the outlet of the food extruder, and air-dry the extruded rubber strip;

[0049] S4: Vacuum drying, and then place the strips in a vacuum oven for drying until the moisture content reaches 31-33%, and the drying temperature is controlled between 53°C and 75°C;

[0050] S5: Molding, molding the rubber strip after vacuum drying to obtain a semi-finished product B;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com