Work method of kitchen garbage treatment device good in breaking effect

A technology of kitchen waste and processing device, which is applied in the direction of grain processing, etc., can solve the problems of waste odor discharge, influence indoor environment, garbage easily spilled, etc., and achieve the effect of reducing odor, improving processing effect, and improving cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

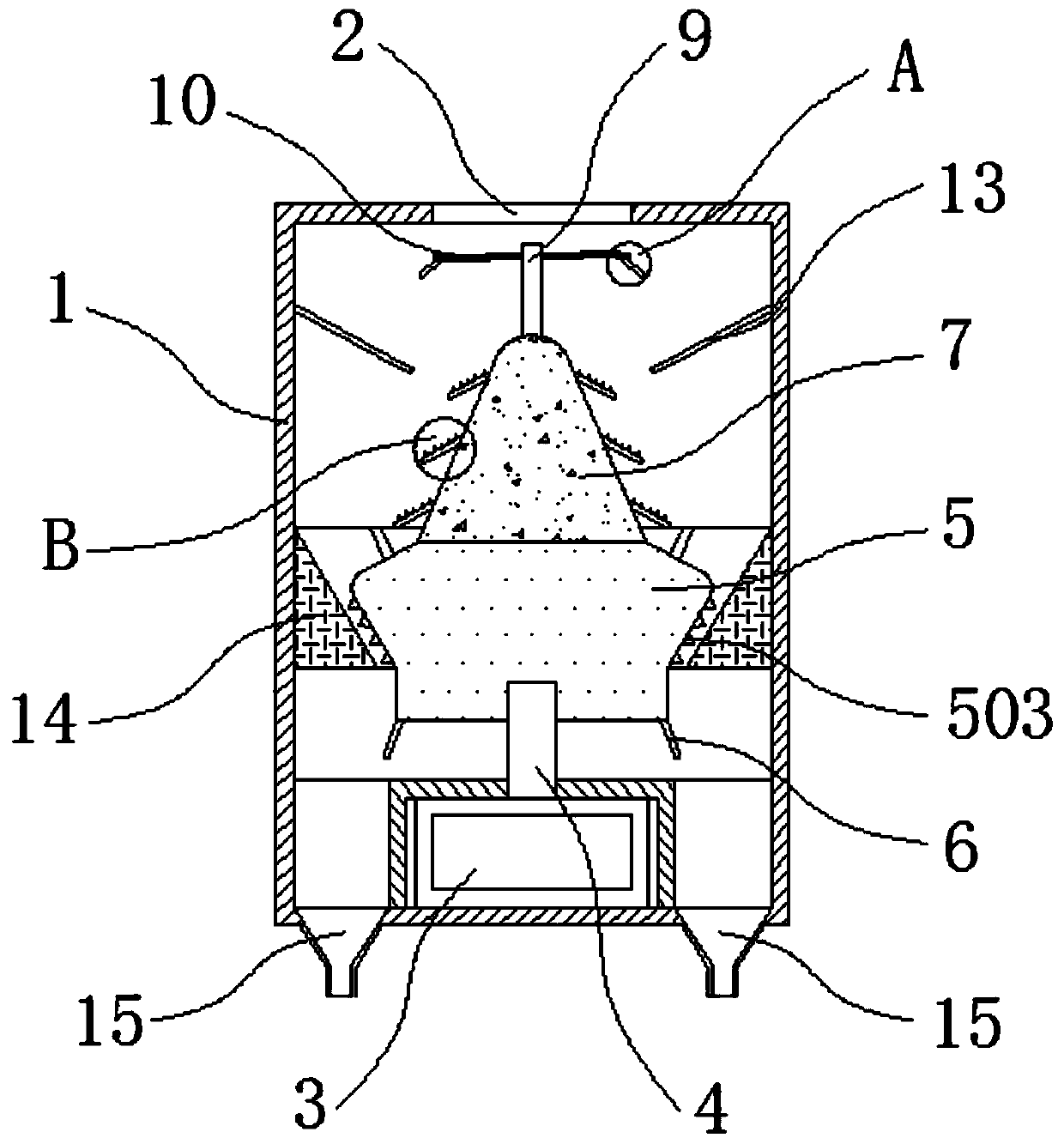

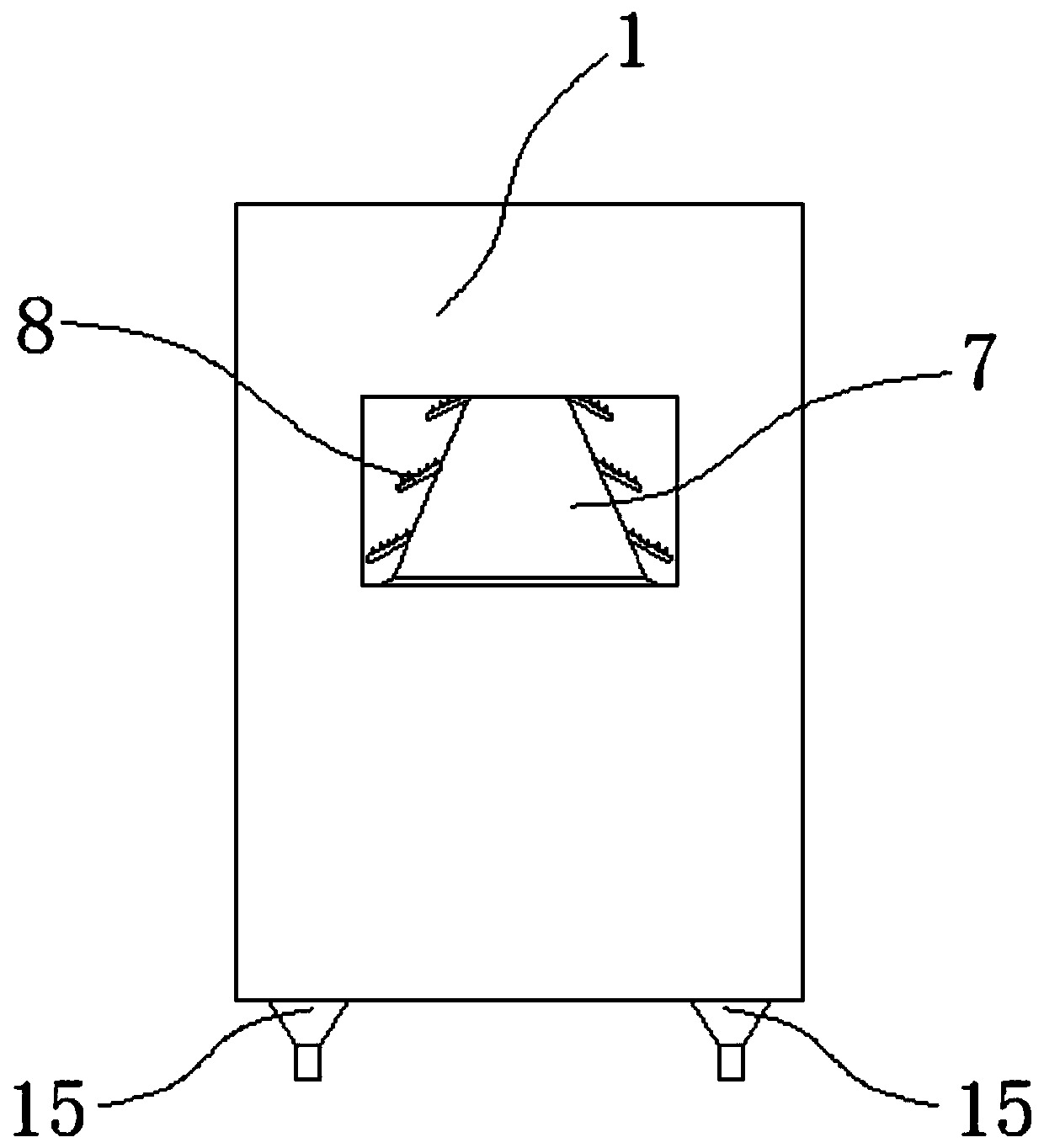

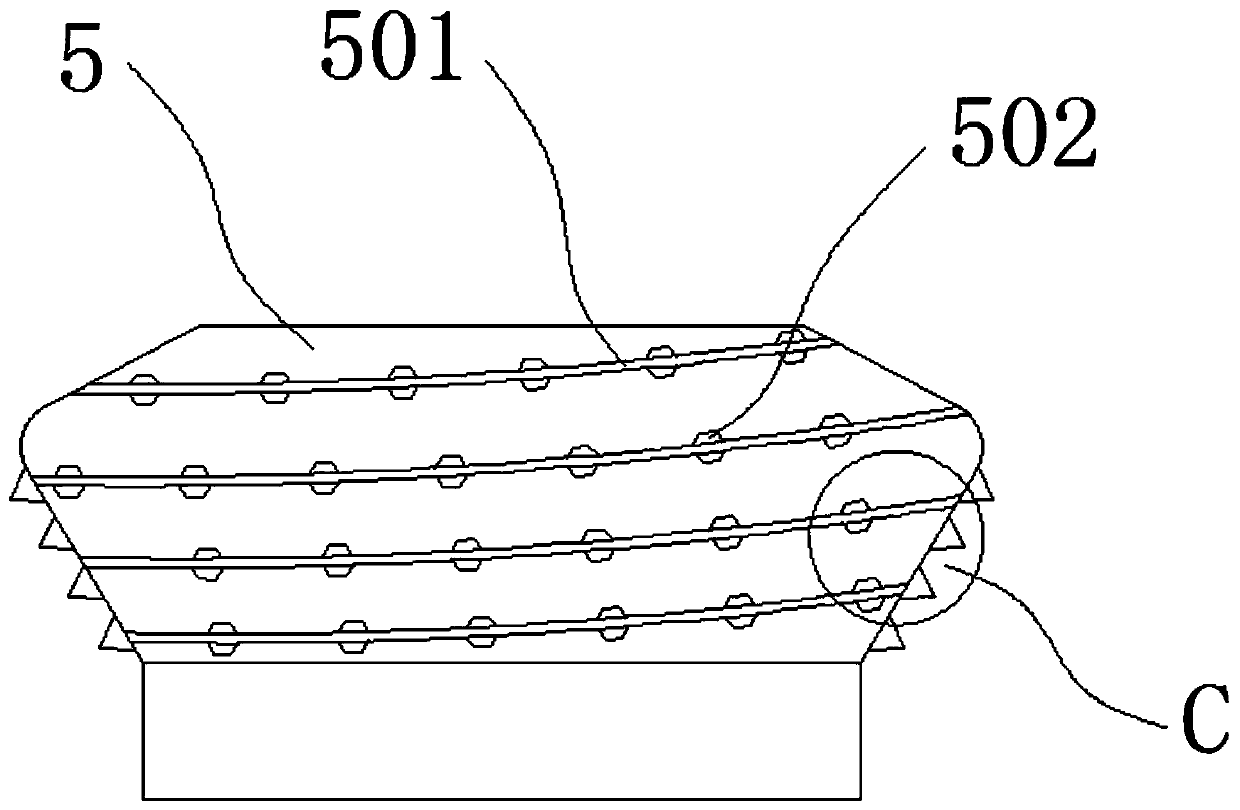

[0032] as attached figure 1 To attach Figure 7 Shown:

[0033] A kitchen waste treatment device with good crushing effect, comprising: a housing 1, a feed port 2, a motor 3, a connecting shaft 4, a crushing block 5, a spiral bar 501, a protrusion 502, a crushing knife 503, a guide plate 6, Conical head 7, crushing plate 8, cutting block 801, fixed rod 9, blade 10, weight 11, inclined plate 12, baffle plate 13, auxiliary block 14, arc bar 1401 and discharge port 15; shell 1 There is a feed port 2 on the top, a motor 3 is fixedly connected to the bottom of the inner wall of the housing 1, a connecting shaft 4 is connected to the top of the motor 3 in rotation, and a crushing block 5 is fixedly connected to the top of the connecting shaft 4, and the surface of the crushing block 5 is fixedly connected to There is a spiral strip 501, and the upper and lower sides of the spiral strip 501 are fixedly connected with protrusions 502, both sides of the crushing block 5 are fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com