Anti-static Coal Mine Underground Power Box Unwinding Device Through Ladder Knives Scratching

An underground power and anti-static technology, applied in the field of coal mines, can solve problems such as affecting the safe operation of equipment, damage to the skin of the wire body, and inability to discharge dust, and achieve the effects of improving service life, preventing static electricity and preventing agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

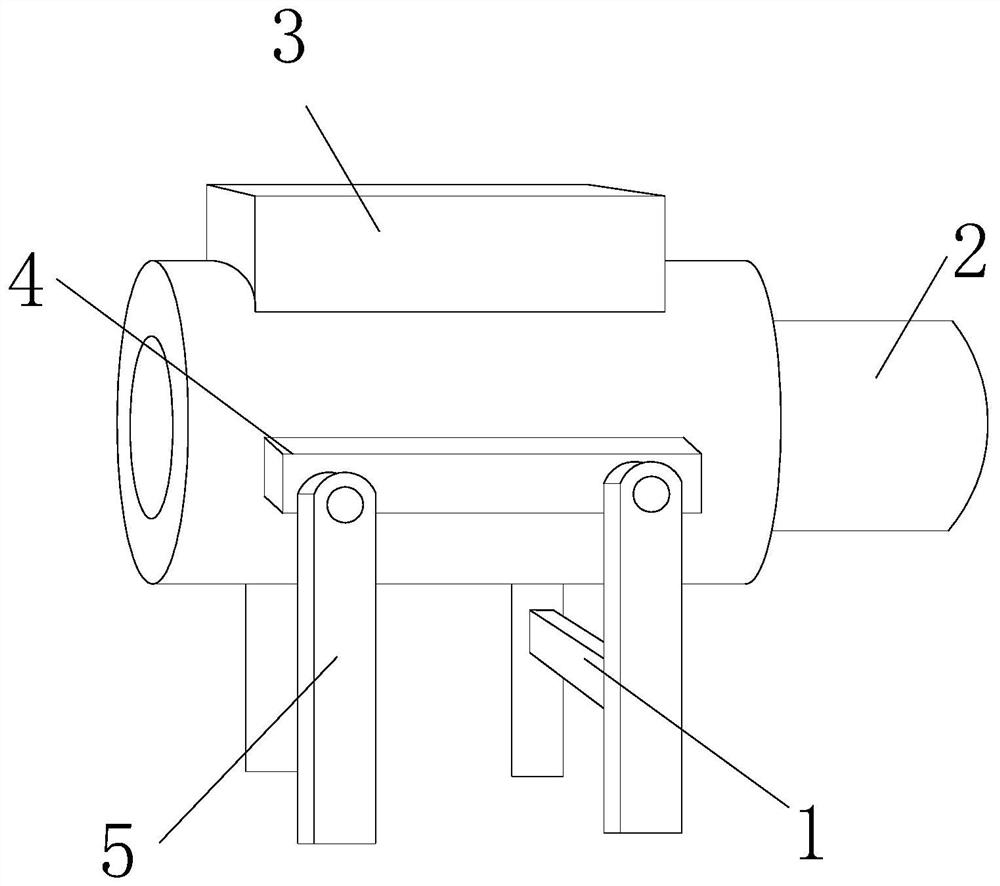

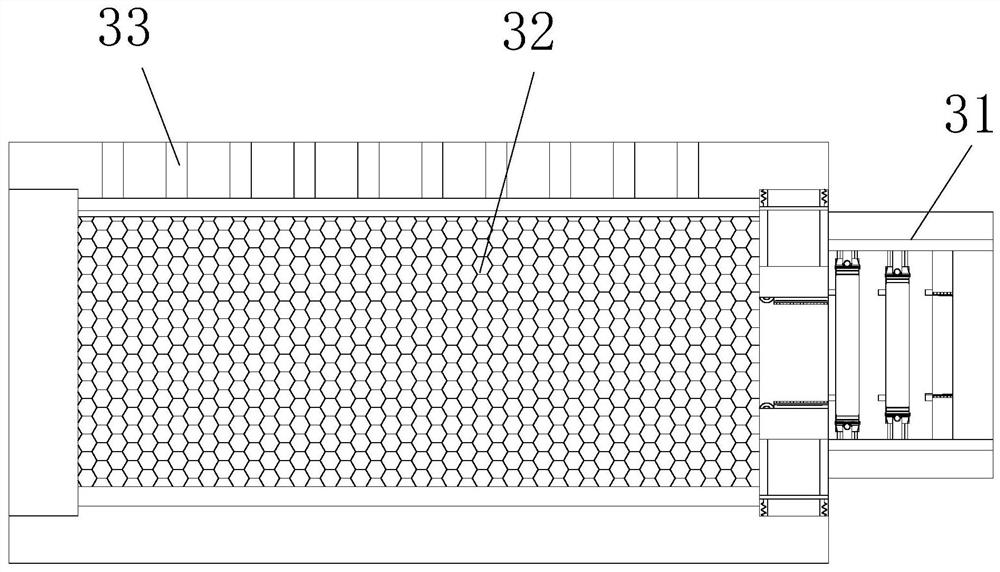

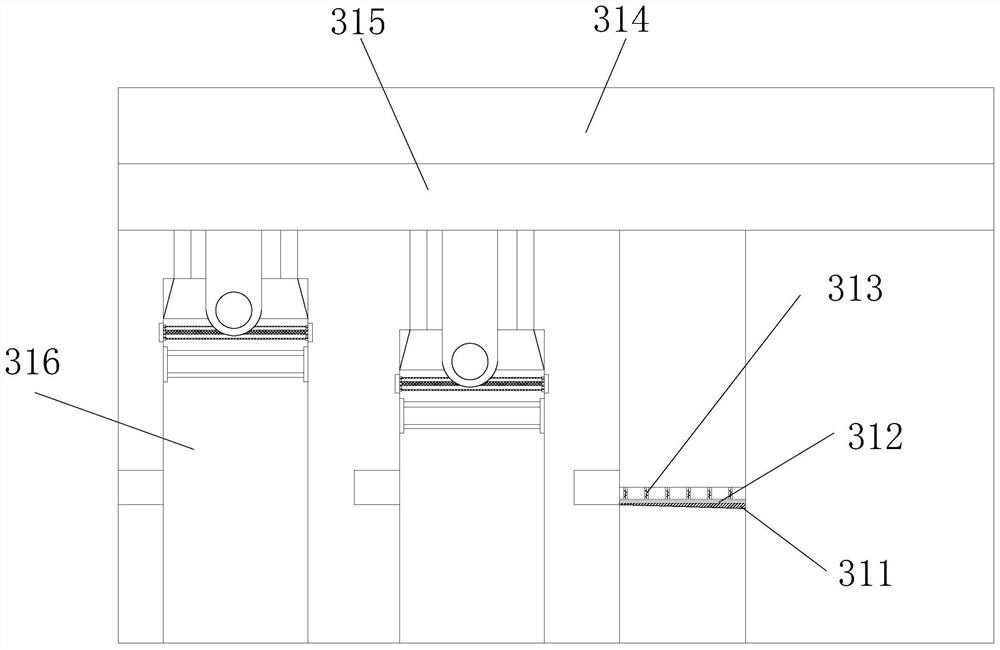

[0029] see figure 1 , the present invention provides an anti-static coal mine power box unwinding device through step-type tool grinding, and its structure includes: a reinforcing rib 1, an output pipe 2, a movable wire unwinding device 3, a mounting seat 4, and a supporting foot 5. The installation The seat 4 is located on the outer end surface of the movable thread withdrawing device 3 and is fixedly connected with the movable thread withdrawing device 3 at the same time, the output pipe 2 is located on the right end surface of the movable thread withdrawing device 3 and the two are connected through each other, and the supporting foot 5 is located on the mounting seat 4 The outer end surface of the outer side is hingedly connected with the mounting seat 4 at the same time, the reinforcing rib 1 is arranged on the inner side end surface of the supporting foot 5 and is fixedly connected with the supporting foot 5 at the same time, and the movable line retreating device 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com