A kind of manufacturing method of large-area titanium-copper thin plate

A production method and technology of copper thin plate, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of high dissolution rate, uneven wall thickness, and inability to apply pressure to process, so as to ensure surface flatness and control dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

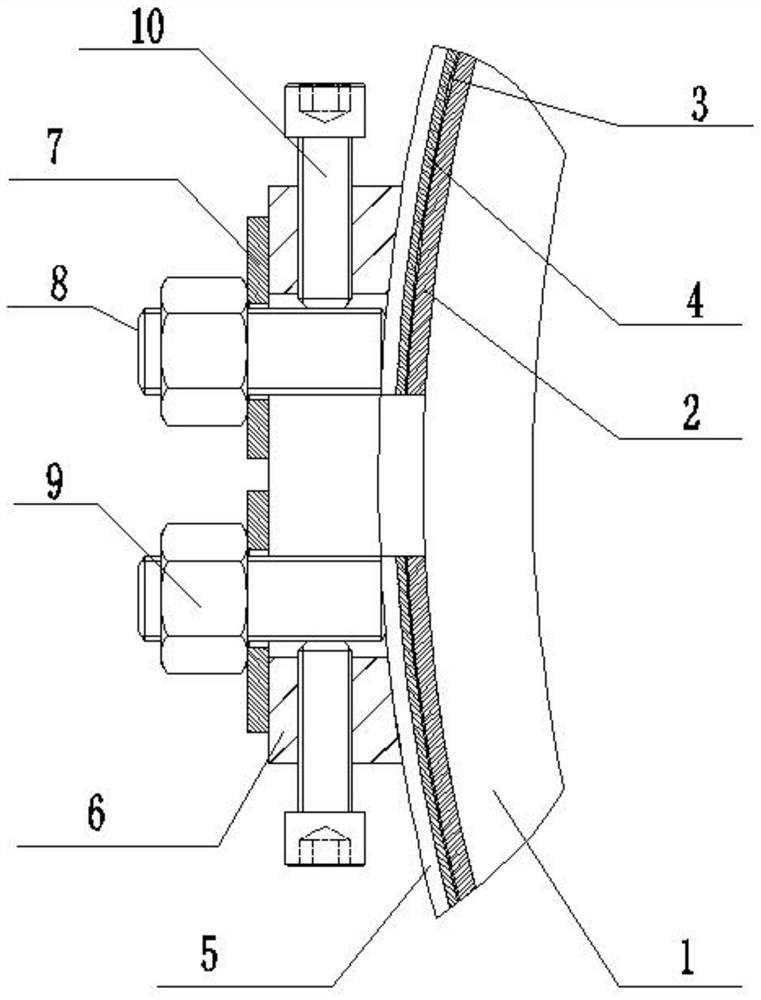

[0030] Cylindrical tensioning tool, reference Figure 1 to 3 The cylindrical tensioning tool includes a sleeve-shaped tensioning tool, the titanium sheet, the Ag solder, and the copper sheet are sequentially positioned in turn along the circumferential direction and mounted on the outer surface of the sleeve-shaped pull-up tool. The sleeve structure of the sleeve-shaped tensioning tool is provided with a pull-up of the tensioning member is applied to the outer to the inner to the titanium sheet, the Ag solder and the copper sheet are applied to the two ends of each layer of the sheet to apply pull in the circumferential direction.

[0031] Further, reference Figure 1 to 3 The cylindrical tensioning tool includes a cylindrical body 1, and the cylinder 1 of the present embodiment employs a cylindrical structure prepared by a material prepared by a material that is not easily deformed, and the cylinder is preferably prepared by stainless steel material; The outer sleeve of the body 1 ...

Embodiment 2

[0039] refer to figure 2 , A method of fabricating a large-area titanium bronze sheet includes the following steps:

[0040] (1) The titanium sheet 1 and the copper sheet 3 are cut and surface treatment; the thickness of the titanium copper sheet is ≤4 mm;

[0041] (2) Position the titanium sheet 1, the Ag solder 2, and the copper sheet 3, sequentially and mounted on the outer surface of the cylindrical tubular tubing tool, the AG solder 2 and the copper sheet 3 are sequentially covered in titanium The surface of the sheet 1; wherein the Ag solder is welded to the surface of the titanium sheet to form an Ag solder layer by the surface of the tinner spot.

[0042] (3) The tubular tubular tubular tubular tubular tubular tape in which the titanium sheet and the copper sheet is applied to the brazing furnace, and the temperature is 0.001 to 0.01Pa, vacuum brazing under conditions of 500 ° C to 900 ° C. 40-60min, then remove the tubular tensioning tool, which is a titanium copper compo...

Embodiment 3

[0054] refer to figure 2 , A large-area titanium bronze sheet fabrication, except that the reaction parameters in the brazing furnace are different from that of Example 2, and the trimness in the brazing furnace is 0.003Pa, the temperature is 500 ° C. The large area of the titanium bronze sheet was performed under conditions, and the composite time was 60 min. The binding ratio of large area titanium copper sheet prepared in this example is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com