Horizontal type orange slitting device

An orange and horizontal lying technology, which is applied in the field of horizontal lying orange cutting devices, can solve the problems of inconvenient eating, inconvenient cleaning, time-consuming and labor-intensive of orange petals, and achieves a small occupied space, convenient storage, and quick cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

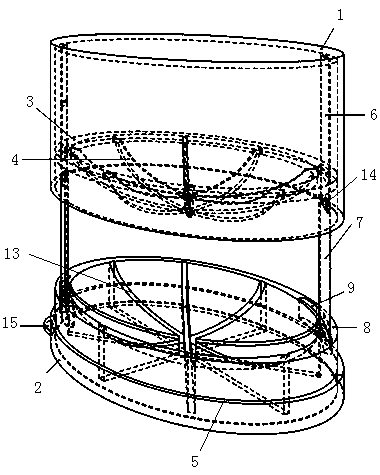

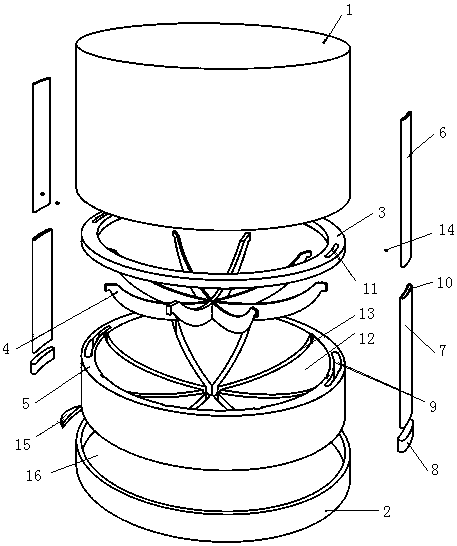

[0026] A horizontal orange cutting device, such as figure 1 and figure 2 , including the slitting knife frame 3 and the slitting knife group, the slitting knife group is located on the slitting knife frame 3, such as image 3 , also includes upper cover 1, positioning assembly, blade groove 13, base 5 and bottom cover, upper cover 1 is arranged on the top of lower cover 2, upper cover 1 adopts upper cover 1 whose section is oval, and upper cover 1 is provided with In the cutting chamber, the slitting knife holder 3 is located in the slitting chamber, and the slitting knife holder 3 is connected to the middle part of the inner side of the upper cover 1, the base 5 is arranged on the bottom cover, and the two sides of the base 5 are provided with lower guide holes 9, Such as Figure 4 , the positioning assembly includes an upper positioning rod 6, a lower positioning rod 7 and a bracket 8, the two sides of the base 5 are respectively provided with a bracket 8, and the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com