Distributed all-electric drive system and grouping control method

An electric drive system and control method technology, applied in electric vehicles, control drive, power management and other directions, can solve problems such as in-depth research on multi-axle special vehicle group drive control strategies, and achieve easy chassis scale expansion, easy wheelbase adjustment, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

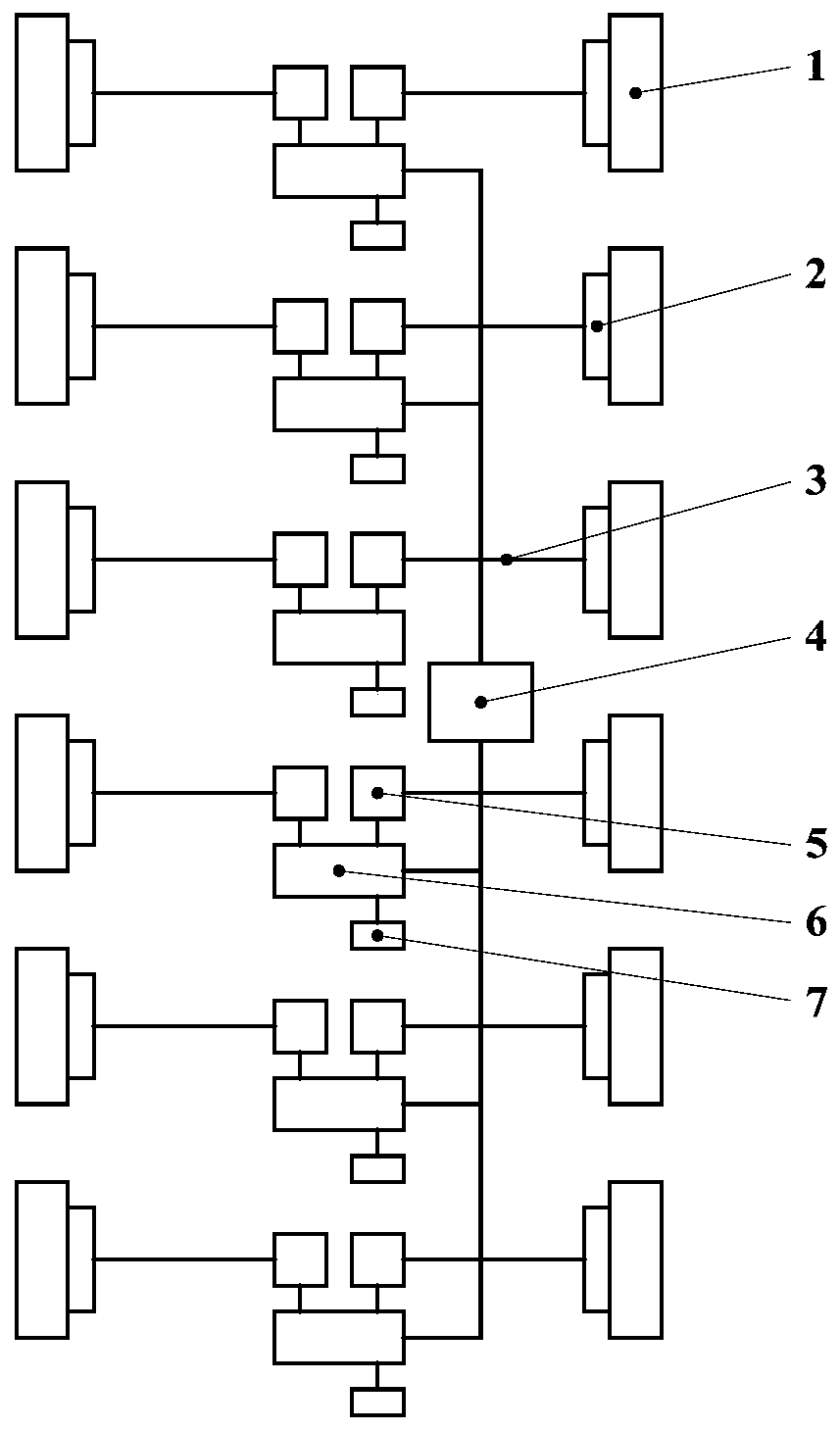

[0039] like figure 1 As shown, the present invention proposes a distributed all-electric drive system, including: a plurality of modular electric drive devices and a drive controller 4; each modular electric drive device includes a wheel 1, a wheel set 2, a wheel drive Axis 3, motor 5 and integrated motor controller 6;

[0040] Each group of modular electric drive devices is equipped with an integrated motor controller 6, and all integrated motor controllers 6 are interconnected with the drive controller 4 to realize the reading of the working state of the motor 5 and the transmission of control signals; the drive controller 4 sends corresponding The control signal is sent to each integrated motor controller 6, and each integrated motor controller 6 drives the motor 5 in the modular electric drive device to work according to the recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com