Intelligent guiding transporting vehicle capable of stacking in multiple directions

A guided transport vehicle, intelligent technology, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of limited steering degree, inability to meet the needs of multi-directional stacking, etc., to achieve strong operability, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

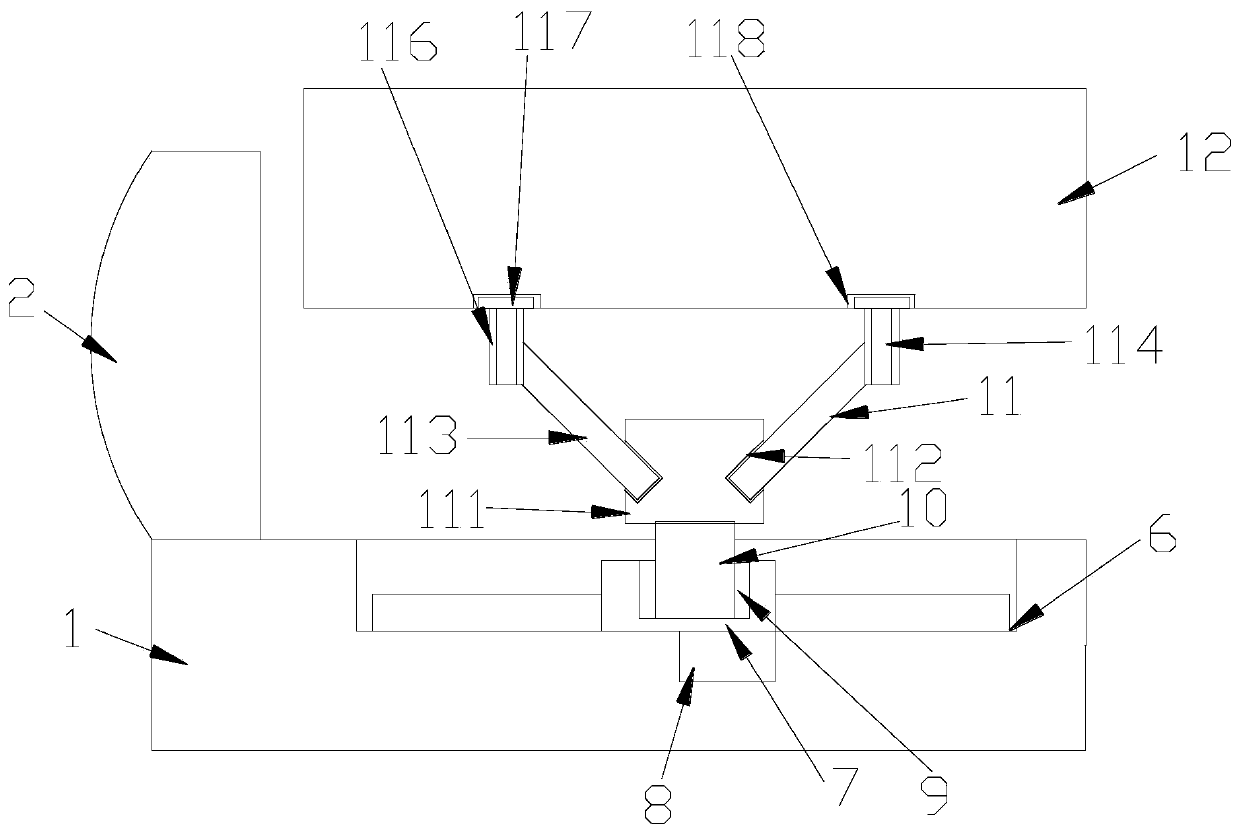

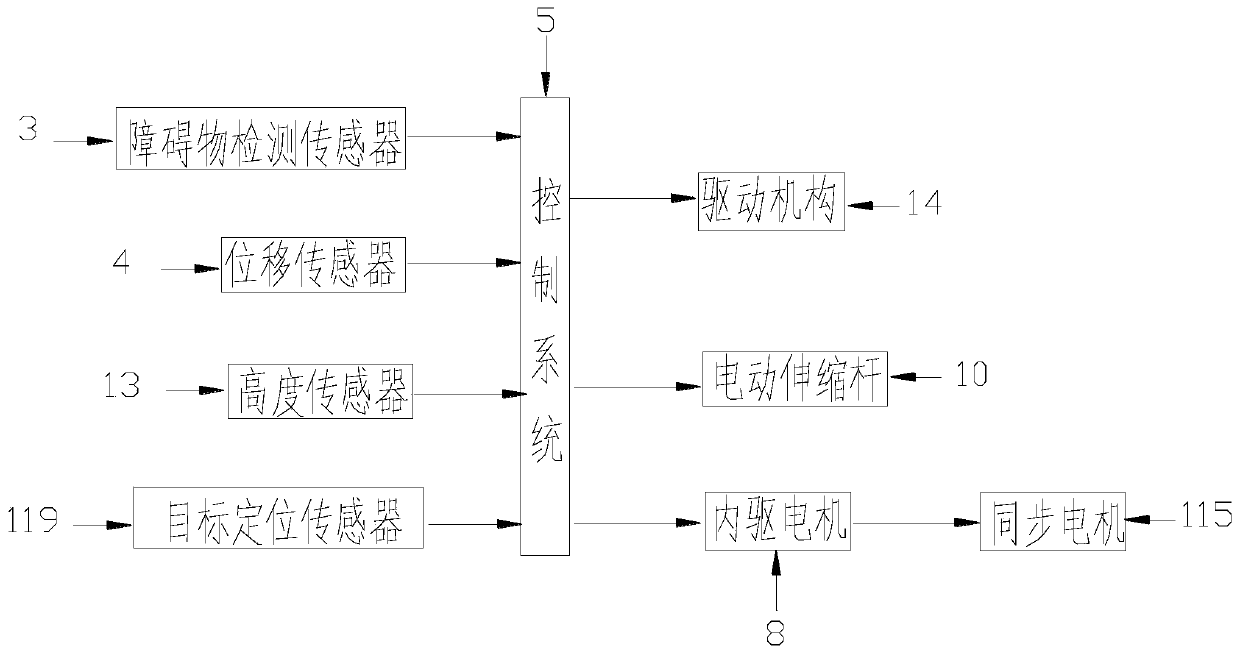

[0024] Example: such as Figure 1-2 As shown, the present invention provides an intelligent guided transport vehicle capable of multi-directional stacking, including a vehicle body 1, a cargo platform 12 and a reversing mechanism 11;

[0025] The front end of the car body 1 is provided with a front end 2, and the front end 2 is provided with an obstacle detection sensor 3 and a displacement sensor 4, and the obstacle detection sensor 3 and the displacement sensor 4 are connected to the control system 5; the car body 1 is provided with a mobile Track 6, the moving track 6 is provided with a mobile base block 7, and one side of the mobile base block 7 is provided with an internal drive motor 8, and the internal drive motor 8 is connected to the control system 5; the mobile base block 7 is provided with an embedded groove 9. An electric telescopic rod 10 is arranged in the embedded groove 9; a reversing mechanism 11 is installed on the top of the electric telescopic rod 10, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com