Novel elevator traction system

A new type of elevator traction technology, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve the problems of short service life and high maintenance costs of traction ropes or traction belts, and achieve maintenance cost savings and weight reduction Requirements, the effect of reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

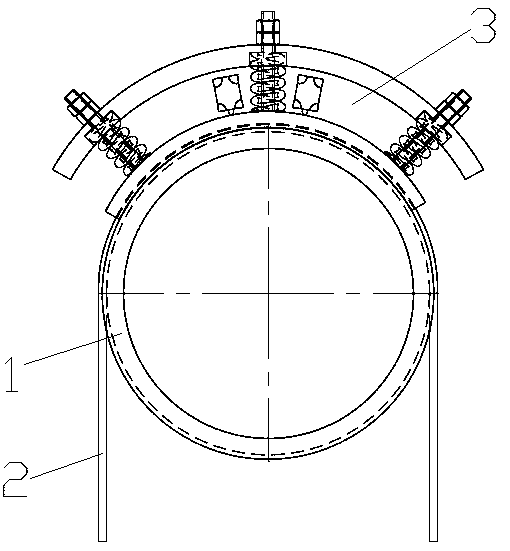

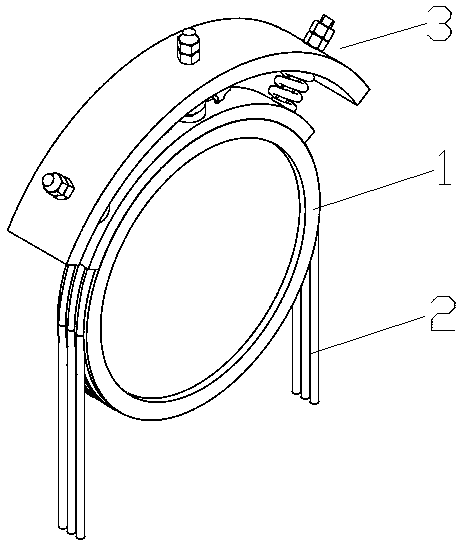

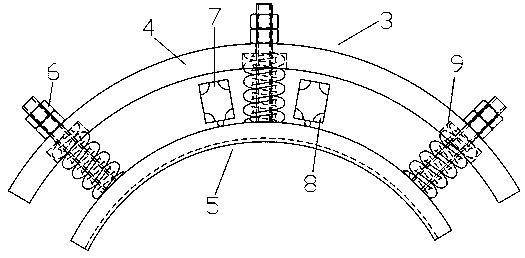

[0020] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-4 As shown, the new elevator traction system includes a traction wheel 1 and a traction rope or traction belt 2 wound on the traction wheel 1, and also includes a At least one pressure loading assembly 3, the pressure loading assembly 3 includes an arc-shaped support frame 4 and an adjustable pressure plate assembly 5 installed on the support frame 4, the support frame 4 and the traction The wheels 1 are concentrically arranged and their relative positions are fixed. The adjustable pressure plate assembly 5 includes an arc-shaped pressure plate 10, a plurality of installation rods 11 and a plurality of compressed elastic elements 12, each of the plurality of elastic elements 12 is respectively Sleeved on a corresponding one of the plurality of installation rods 11, the lower ends of the plurality of instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com