New multi-wedge composite steel belt traction elevator system

An elevator system and composite steel technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of large traction machines, polluted machine rooms, and complicated maintenance, and can reduce building space and increase stickers. Combined area, simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

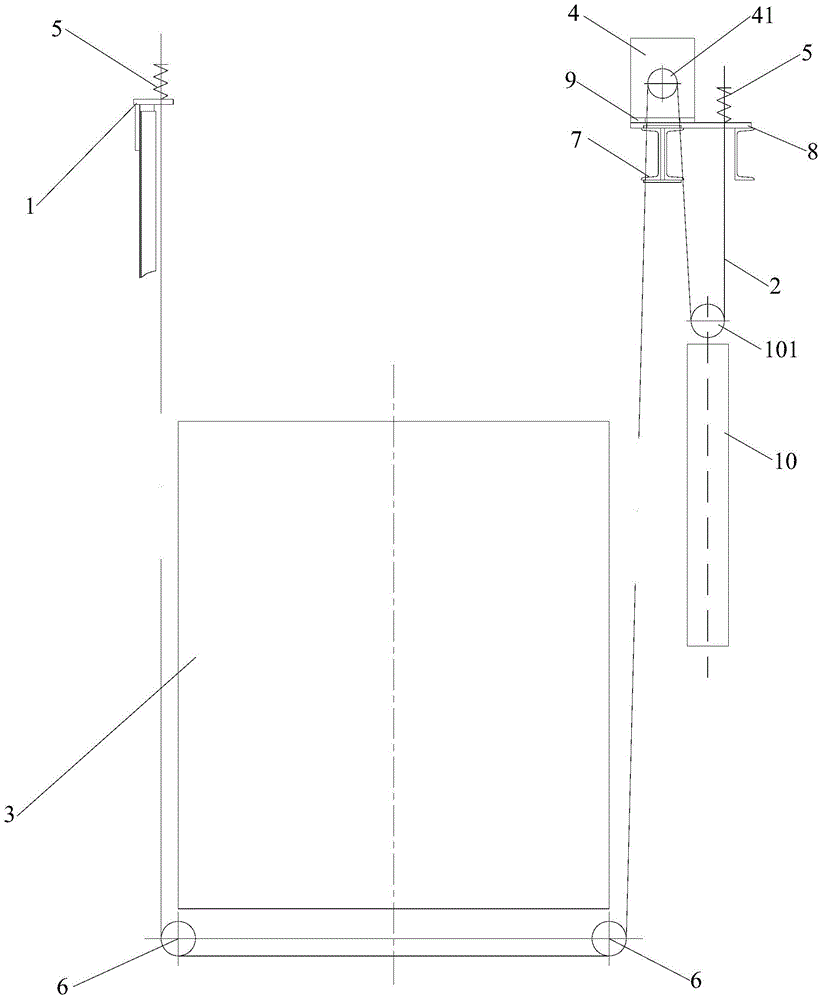

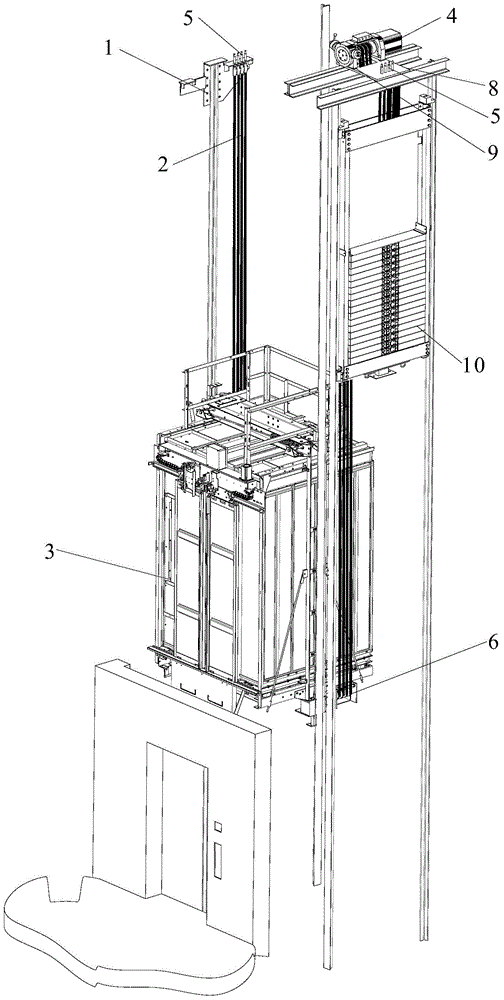

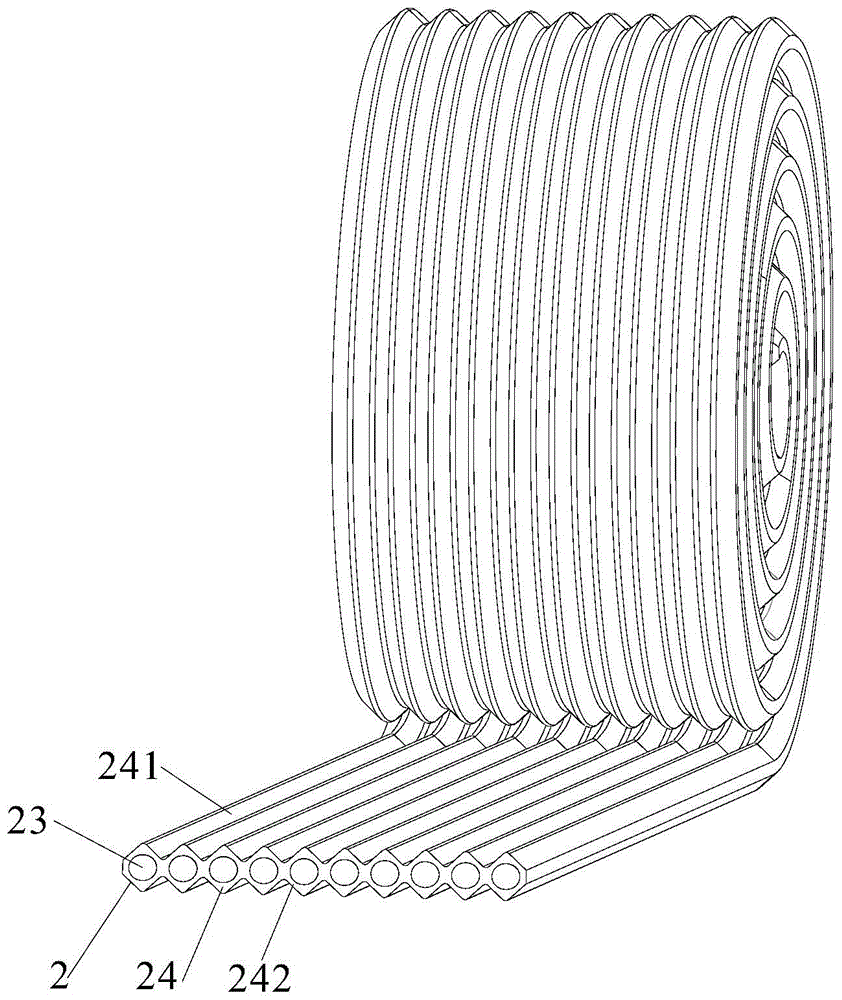

[0033] Such as Figure 1 to Figure 4The new multi-wedge composite steel belt traction elevator system of the illustrated embodiment includes a car side support 1, a multi-wedge composite steel belt 2, a car 3, a multi-wedge composite steel belt traction machine 4 and a counterweight balance system 10, The multi-wedge composite steel strip 2 includes a multi-wedge composite steel strip head end 21 and a multi-wedge composite steel strip end 22 . The head end 21 of the multi-wedge-shaped composite steel belt is connected to the side support frame 1 of the car, and the end 22 of the multi-wedge-shaped composite steel belt passes through the bottom of the car 3 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com