Heating device of flat glass furnace and use method thereof

A flat glass and heating device technology, which is applied to glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve the problems of energy loss, accelerated pool wall tile loss rate, etc., to reduce external loads, improve efficiency, and solve Joule heat The effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

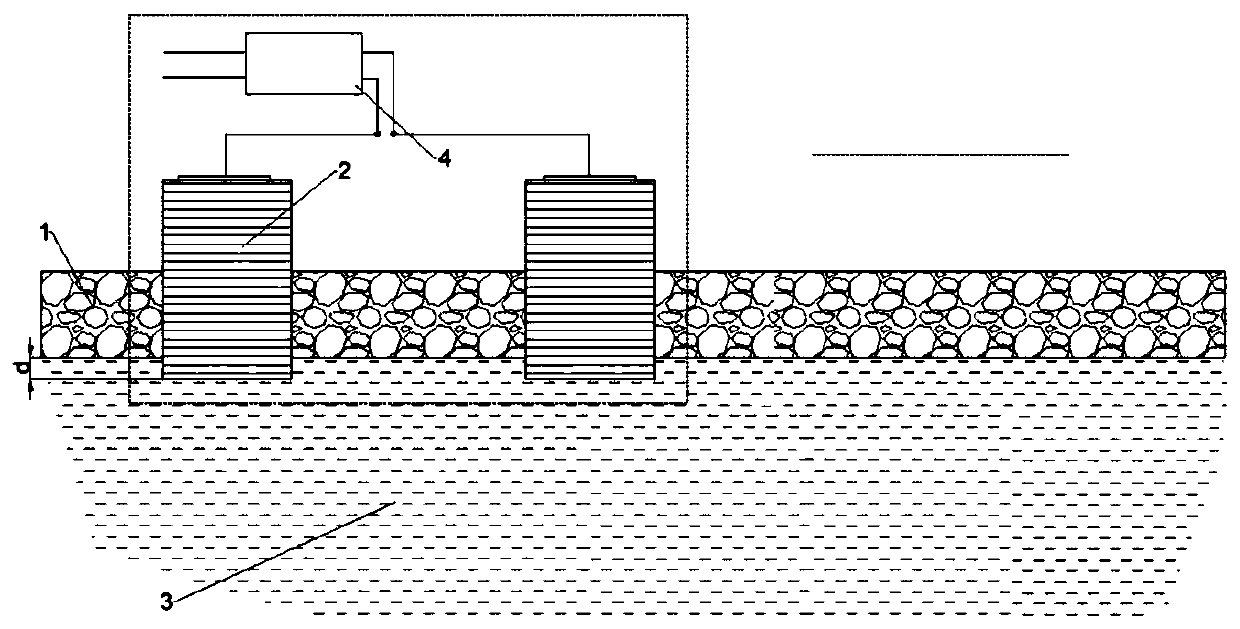

[0031] Such as figure 1 As shown, a heating device for a flat glass kiln of the present invention includes an electrode heating brick 2 and a power supply device 4; the electrode heating brick 2 is an even number, and all the electrode heating bricks 2 are set beyond the inner wall of the pool wall brick 1 of the kiln; Each power supply device 4 communicates with two electrode heating bricks 2. After the power supply device 4 is energized, the two electrode heating bricks 2 heat the glass liquid 3 in the kiln under the action of Joule heat to form a group of heating units, and the kiln is separated. into multiple sets of heating units. In this embodiment, the power supply device 4 is an AC-DC converter with AC input, that is, an AC / DC converter; after the electrode heating brick 2 exceeds th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com