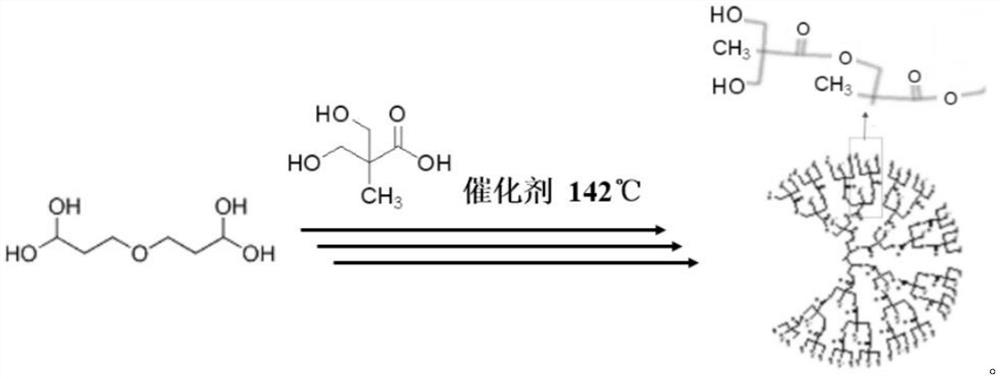

A high-strength environmentally friendly lightweight polyurethane foam using hyperbranched polyester polyol as a crosslinking agent and its preparation method

A technology of hyperbranched polyester and polyurethane foam is applied in the field of high-strength, environment-friendly and lightweight polyurethane foam and its preparation, and can solve the problems of high foam volatilization and poor foam strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) In the reaction device equipped with stirring, temperature control and nitrogen protection, keep the addition temperature at 142°C, add 3.3g of dipropylene glycol, 0.02g of PTSA, and 10.7g of dimethylolpropionic acid to the reaction vessel in sequence, to Stir and react at a speed of 600r / min for 3 hours; keep the reaction temperature and stirring speed constant, add 0.04g PTSA and 21.4g dimethylol propionic acid to the reaction vessel in turn, and react for 4.5 hours; keep the reaction temperature and stirring speed constant , sequentially add 0.08g PTSA, 42.8g dimethylol propionic acid to the reaction vessel, and react for 4.5 hours; after the reaction, pour out the product, return to room temperature and solidify, and grind the hyperbranched polyester polyol into powder.

[0029] (2) Add 222g combined polyol, 18g hyperbranched polyester polyol powder, 1.8g organosilicon foam stabilizer, 1.2g catalyst, 18g deionized water in the feed kettle, and hyperbranched polyo...

Embodiment 2

[0034] (1) In the reaction device installed with stirring, temperature control and nitrogen protection, keep the addition temperature at 142°C, add 3.3g of dipropylene glycol, 0.02g of PTSA, and 10.7g of dimethylol propionic acid to the reaction vessel in sequence, to Stir and react at a speed of 600r / min for 3 hours; keep the reaction temperature and stirring speed constant, add 0.04g PTSA and 21.4g dimethylol propionic acid to the reaction vessel in turn, and react for 4.5 hours; keep the reaction temperature and stirring speed constant , add 0.08g PTSA, 42.8g dimethylolpropionic acid to the reaction container in turn, and react for 5 hours; after the reaction, pour out the product, return to room temperature and solidify, and grind the hyperbranched polyester polyol into powder.

[0035](2) Add 198g combined polyol, 6g hyperbranched polyester polyol powder, 6g organosilicon foam stabilizer, 1.2g catalyst, 12g deionized water in the feed kettle, with the stirring speed of 650...

Embodiment 3

[0040] (1) In the reaction device equipped with stirring, temperature control and nitrogen protection, keep the addition temperature at 140°C, add 3.3g of dipropylene glycol, 0.02g of PTSA, and 10.7g of dimethylolpropionic acid to the reaction vessel in sequence, to Stir and react at a speed of 850r / min for 3 hours; keep the reaction temperature and stirring speed constant, add 0.04g PTSA and 21.4g dimethylolpropionic acid to the reaction vessel in turn, and react for 4.5 hours; keep the reaction temperature and stirring speed constant , sequentially add 0.08g PTSA, 42.8g dimethylol propionic acid to the reaction vessel, and react for 4.5 hours; after the reaction, pour out the product, return to room temperature and solidify, and grind the hyperbranched polyester polyol into powder.

[0041] (2) Add 240g combined polyol, 12.6g hyperbranched polyester polyol powder, 3g organosilicon foam stabilizer, 2.4g catalyst, 30g deionized water in the feed kettle, with the stirring speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com