Method for preparing low-density TPU bead foam by extrusion foaming based on coupling modification of polytetrafluoroethylene and talc powder

A kind of polytetrafluoroethylene, extrusion foaming technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

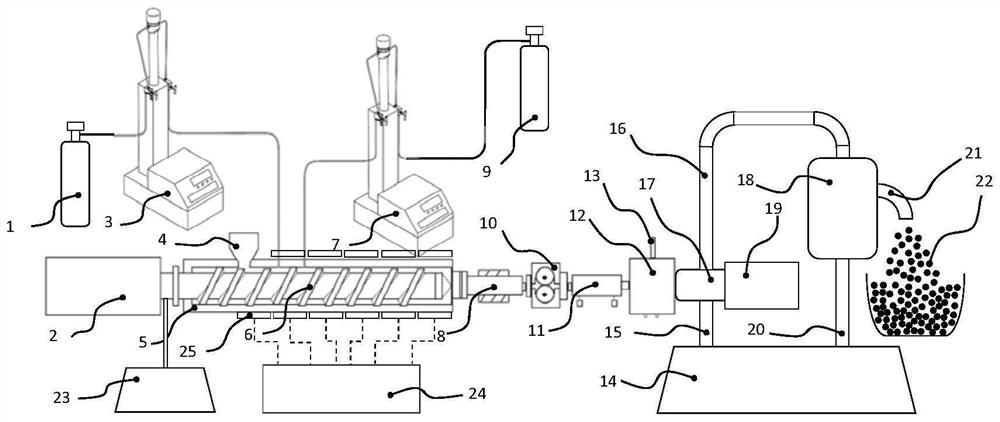

Method used

Image

Examples

Embodiment 1

[0059] The raw material is polyester TPU with a hardness of 80A and a density of 1.20g / cm 3 (@23 ℃), the addition amount is 87.7wt%; The mesh number of PTFE solid powder is 100 mesh, and the addition amount is 2wt% (mass fraction); The mesh number of talcum powder is 3000 mesh, and the addition amount is 4wt%; The critical fluid I is carbon dioxide with a purity of 99.9%, and the supercritical fluid II is nitrogen with a purity of 99.5%. The injected amount of carbon dioxide is 6.0wt%, and the injected amount of nitrogen is 0.3wt%.

[0060] The twin-screw temperature is set to 180°C; the barrel temperature of the twin-screw extruder is set to 60°C–160°C–180°C–180°C–180°C–180°C–180°C–180°C–180°C from the hopper to the extrusion port ℃–180℃–170℃–170℃, the screw speed is 30 rpm; the temperature of the static mixer is set to 150℃; the control pressure of the gear pump is set to 12.5MPa, and the temperature of the gear pump is set to 150℃ ; The temperature of the melt cooler is se...

Embodiment 2

[0063] The raw material is polyether TPU with a hardness of 85A and a density of 1.20g / cm 3 (@23 ℃), the addition is 87.8wt%; The order number of PTFE solid powder is 400 orders, and the addition is 6wt%; The order number of talcum powder is 5000 orders, and the addition is 2wt%; Supercritical fluid I is Carbon dioxide with a purity of 99.9%, supercritical fluid II is nitrogen with a purity of 99.5%; the injected amount of carbon dioxide is 4.0wt%, and the injected amount of nitrogen is 0.2wt%.

[0064] The twin-screw temperature is set at 200°C; the barrel temperature of the twin-screw extruder is set at 60°C–160°C–180°C–200°C–200°C–200°C–200°C–200°C–190°C from the hopper to the extrusion port ℃–190℃–180℃–180℃, the screw speed is 40 rpm; the temperature of the static mixer is set to 160℃; the control pressure of the gear pump is set to 16MPa, and the temperature of the gear pump is set to 160℃; The temperature of the melt cooler is set to 140°C; the temperature of the extrus...

Embodiment 3

[0067] The raw material is polyether TPU with a hardness of 95A and a density of 1.20g / cm 3 (@23 ℃), the addition is 89.6wt%; The order number of PTFE solid powder is 1000 orders, and the addition amount is 3wt%; The order number of talcum powder is 5000 orders, and the addition amount is 5wt%; Supercritical fluid I is Carbon dioxide with a purity of 99.9%, supercritical fluid II is nitrogen with a purity of 99.5%; the injected amount of carbon dioxide is 2.0wt%, and the injected amount of nitrogen is 0.4wt%.

[0068] The twin-screw temperature is set to 220°C; the barrel temperature of the twin-screw extruder is set to 60°C–160°C–200°C–210°C–220°C–220°C–220°C–220°C–210°C from the hopper to the extrusion port ℃–200℃–180℃–180℃, the screw speed is 25 rpm; the temperature of the static mixer is set to 170℃; the control pressure of the gear pump is set to 20MPa, and the temperature of the gear pump is set to 170℃; The temperature of the melt cooler is set to 145°C; the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com